Combined impeller

A combined, impeller technology, used in non-variable volume pumps, components of pumping devices for elastic fluids, machines/engines, etc., can solve problems such as difficult positioning, insufficient strength, and easy deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

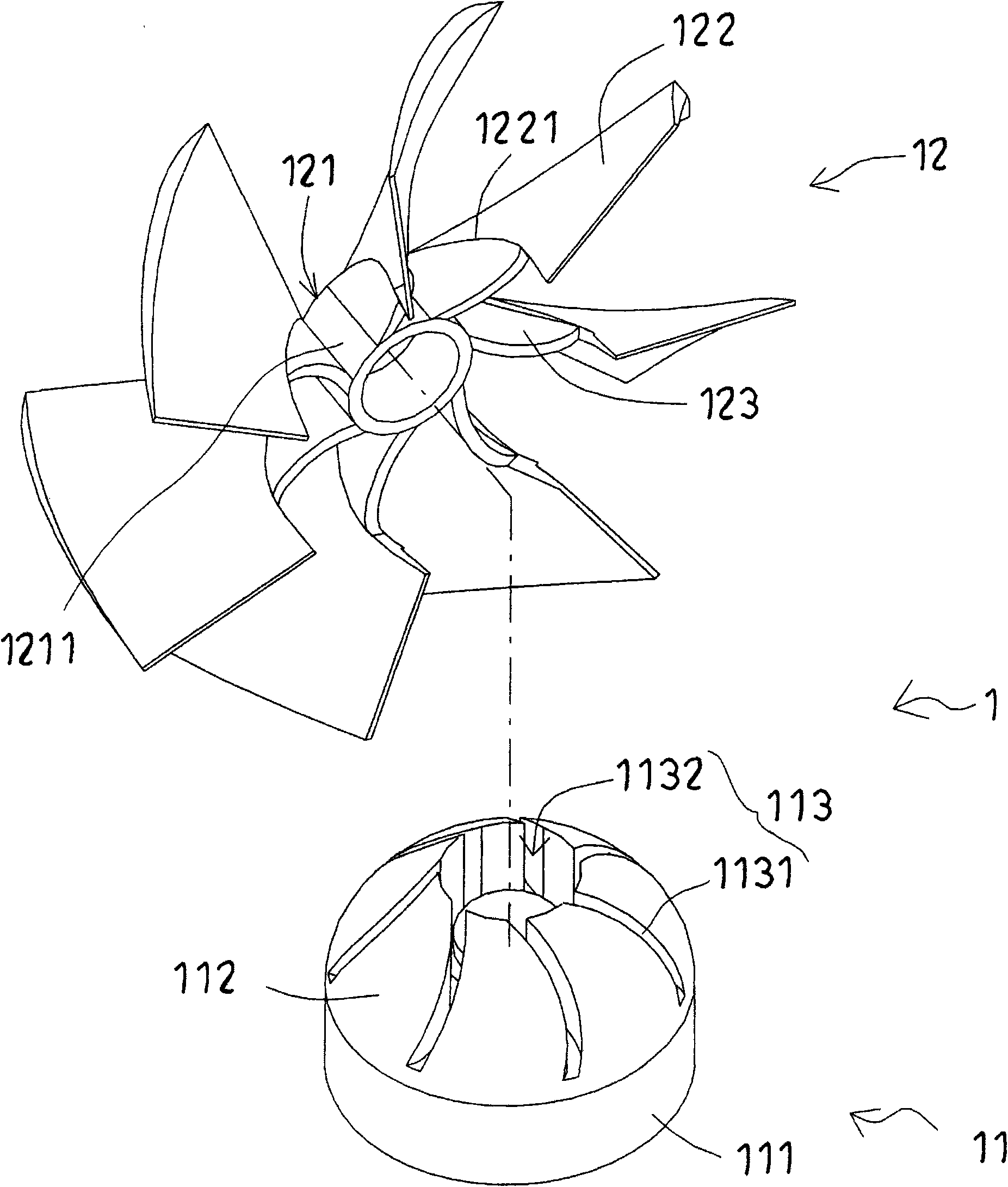

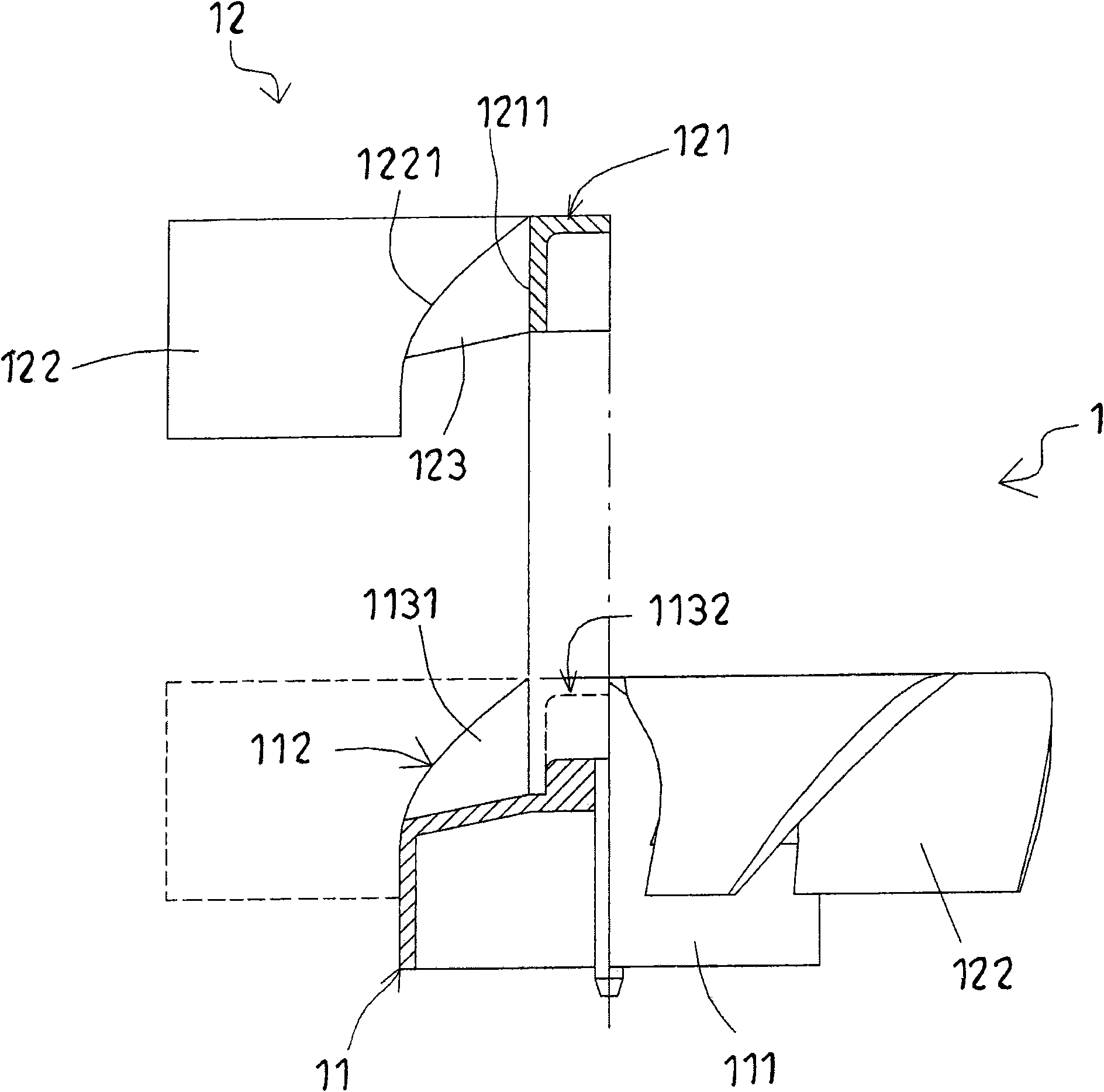

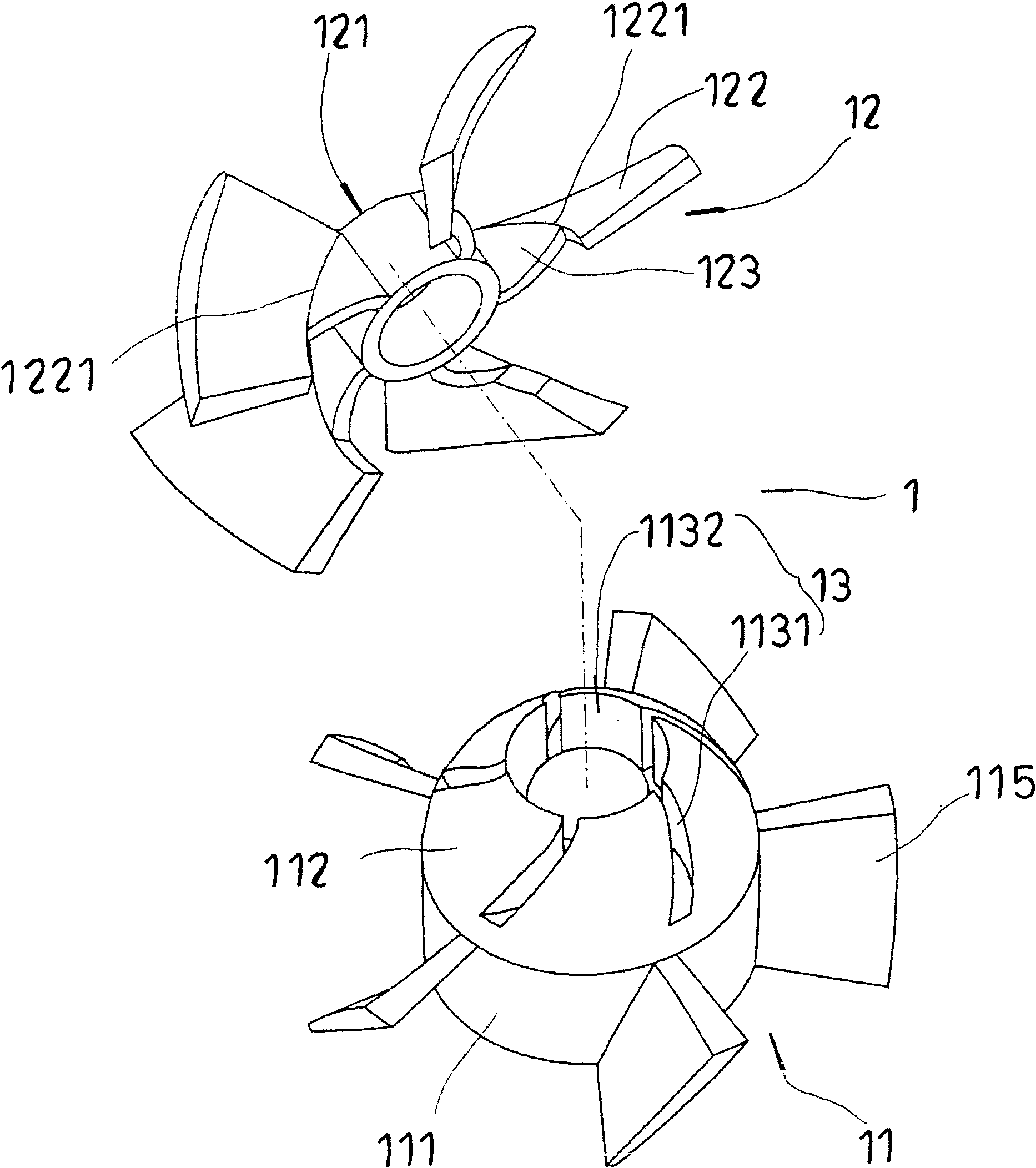

[0068] Please cooperate with reference figure 1 , figure 2 As shown, it is the first preferred embodiment of the combined impeller of the present invention; the combined impeller 1 includes: an annular seat 11 and an impeller 12; wherein:

[0069] The annular seat body 11 has a hub 111, the hub 111 is provided with an arc-shaped diversion surface 112, and a ring body hole group 113 is arranged on the annular seat body 11, and the ring body hole group 113 includes a plurality of concave holes. The card groove 1131 and a recessed ring body hole 1132, and each card groove 1131 communicates with the ring body hole 1132 and the flow guide surface 112; in addition, the annular seat 11 can further be provided with several booster blades at the periphery 114 (please refer to Figure 6 ), each supercharging vane 114 is located in the trailing edge of the air passage between two adjacent vanes 122 of the impeller 12;

[0070] There is a ring body 121 embedded in the ring body hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com