Nonaqueous electrolyte secondary cell, insulating plate and manufacturing method thereof

A non-aqueous electrolyte and secondary battery technology, which is applied in the direction of non-aqueous electrolyte batteries, electrolyte battery manufacturing, secondary batteries, etc., can solve the problems of non-aqueous electrolyte secondary batteries that cannot be used, and achieve improved vibration resistance, improved resistance Shock, effect of promoting attachment operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] An embodiment of the present invention is described in detail below based on the drawings.

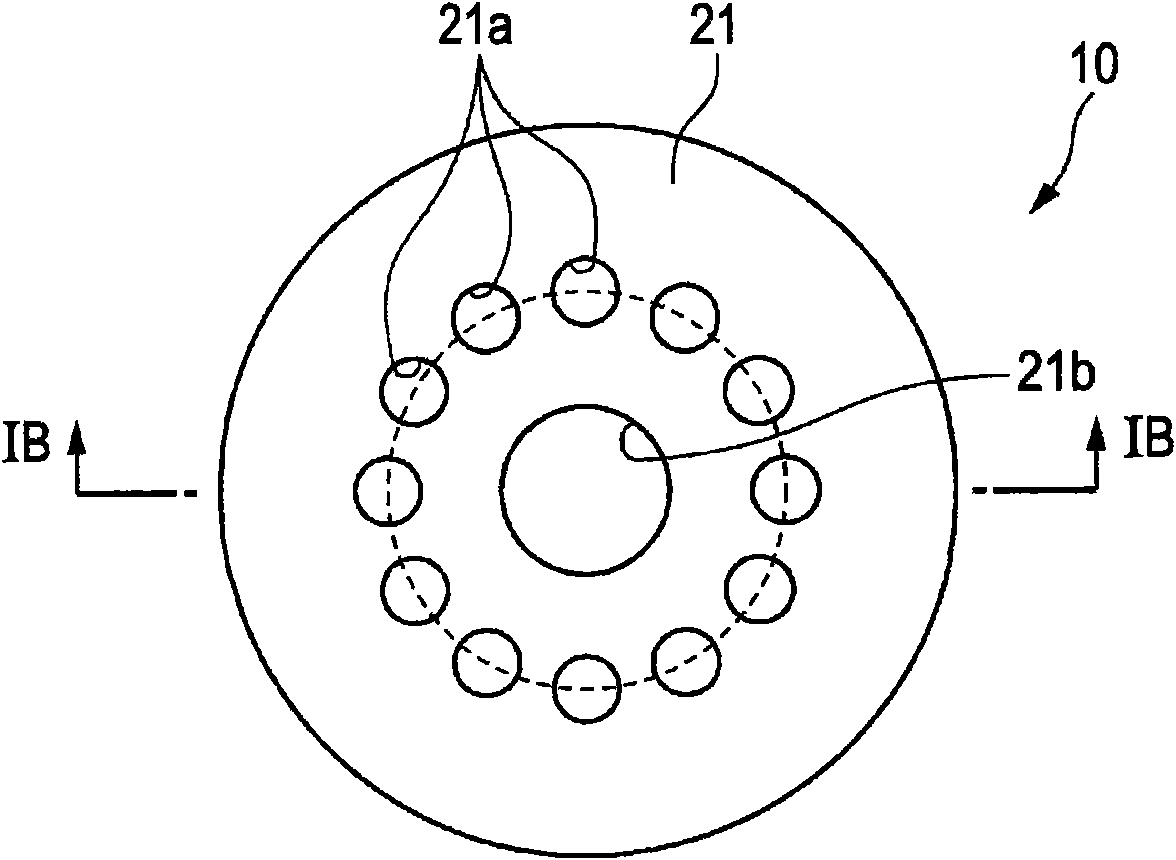

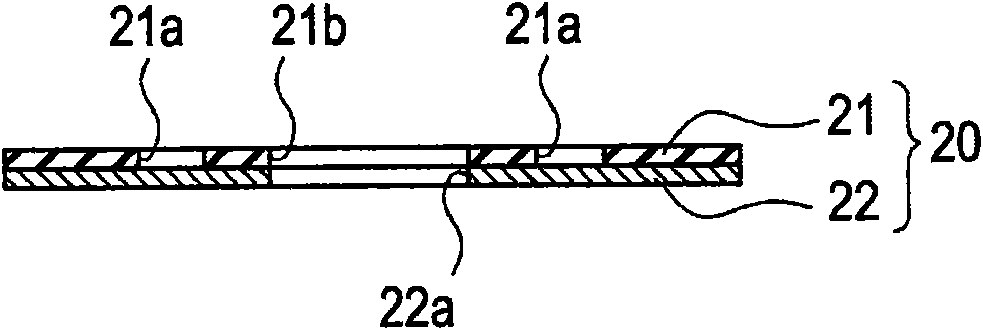

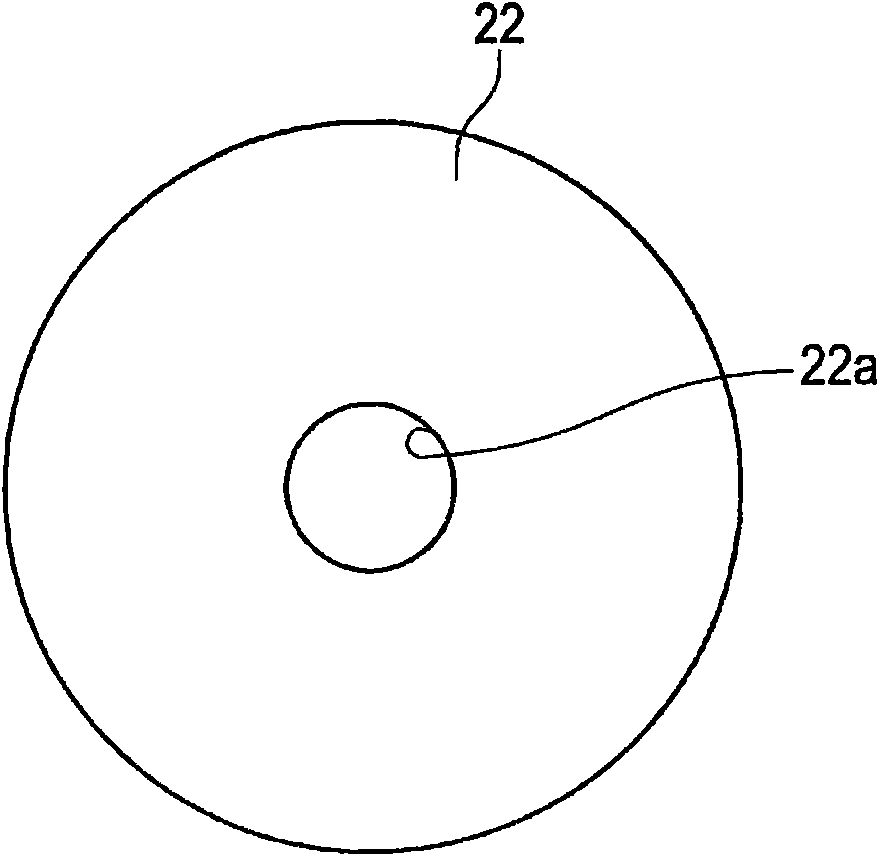

[0051] Figure 1A is a plan view of an insulating plate for a non-aqueous electrolyte secondary battery according to an embodiment of the present invention, Figure 1B is along Figure 1A The cross-sectional view taken on the line IB-IB, and Figure 1C is a plan view of the filter component. figure 2 It is a graph showing the comparison of the electrolyte injection time between the case where the nonwoven fabric is used for the insulating board and the case where the nonwoven fabric is not used. image 3 It is a table and a graph showing the effect of the maximum pore size of the nonwoven fabric on the electrolyte injection time. Figure 4 It is a graph showing the comparison of the amount of pollutants entering when non-woven fabrics are used for insulating panels and when non-woven fabrics are not used. Figure 5 It is a table and a graph showing the effect of the maximu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com