Bipolar plate for proton exchange membrane fuel cell

A proton exchange membrane and fuel cell technology, applied in the direction of fuel cells, fuel cell components, battery electrodes, etc., can solve the problem that the conductivity is difficult to meet the increasing requirements of bipolar plates, reduce battery performance and life, Increase the internal resistance of the battery and other issues to achieve the effect of saving valuable modified materials, improving performance and life, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

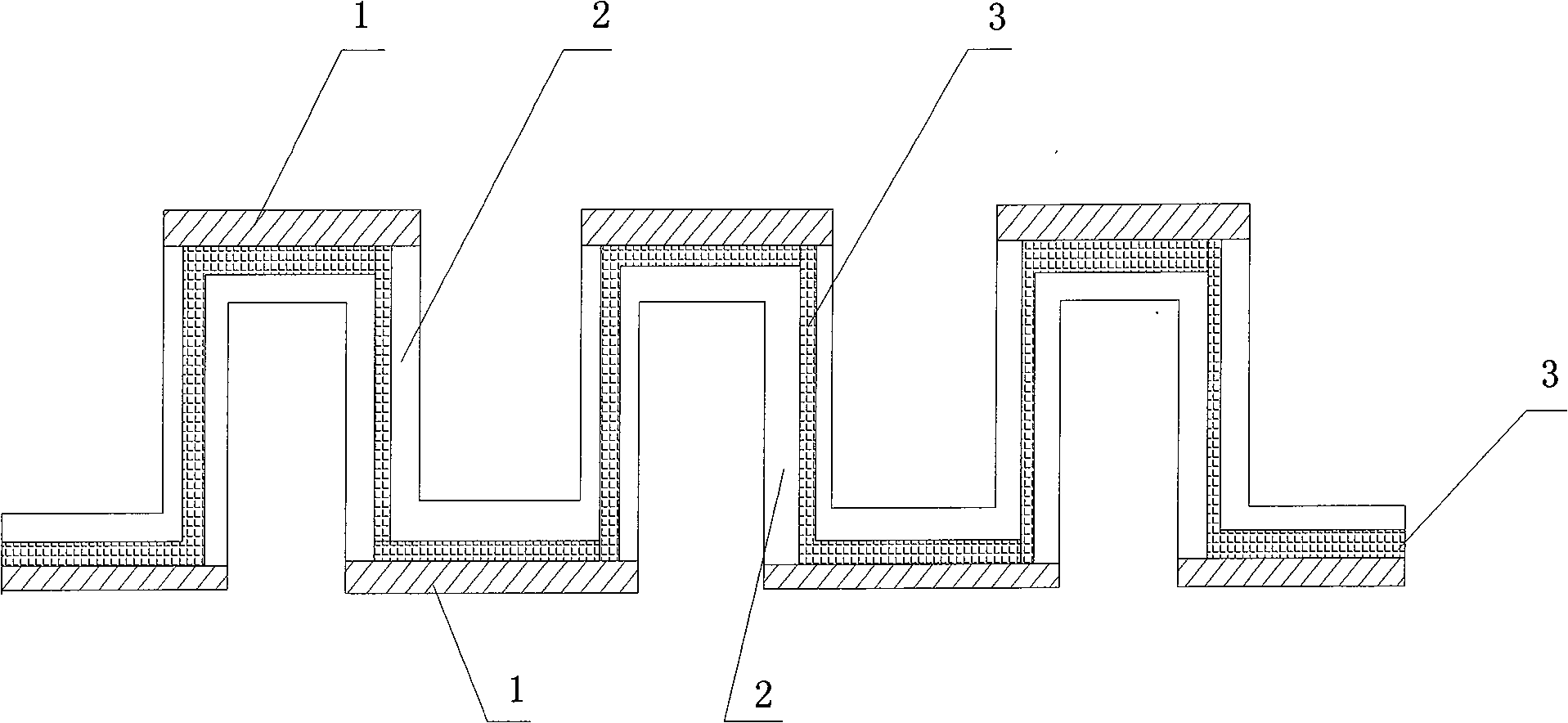

Image

Examples

Embodiment 1

[0022] The 316L stainless steel plate with a thickness of 0.1mm is punched out of the reaction gas flow channel and the inlet and outlet channels of hydrogen, air and cooling water. The width of the protrusion and depression of the gas flow channel is 1.5mm, and the depth is 2.0mm. The decontamination powder cleans the oil on the surface of the bipolar plate and then dries it.

[0023] Use the 200 series passivation solution from Tianchang Huajin Anticorrosion Cleaning Material Factory for passivation treatment: immerse the bipolar plate in an aqueous solution of stainless steel passivation solution with a volume ratio of 50%, soak for 60s at 20°C, take it out and use deionized water Cleaning; put it into a 3% sodium hydroxide solution by mass and soak for 5 minutes, take it out, clean it with deionized water, and let it dry naturally in the atmosphere.

[0024] Use black electroplating protective paint to coat the entire area of the bipolar plate with flow channels, then he...

Embodiment 2

[0027] The 0.2mm thick TC4 plate (Ti-6Al-4V) is punched out of the reactant flow channel and the inlet and outlet channels of hydrogen, air and cooling water. . Use decontamination powder to clean the oil on the surface of the bipolar plate, wash it with deionized water, and dry it.

[0028] The titanium bipolar plate stamped with flow field grooves was heated in a muffle furnace at 600 °C for 60 min in an air environment to oxidize the surface. Use black electroplating protective paint to coat the entire area of the bipolar plate with flow channels, then heat it in an oven at 60°C for 30min, take it out, and cool it to room temperature. Use 2000# sandpaper to polish off the electroplating protective paint and passivation layer on the raised part of the gas flow channel of the bipolar plate, so that the titanium alloy substrate is exposed at this place, and then perform gold plating. The gold plating solution is: Au (in KAu(CN) 2 form), 6g / L; K 2 HPO 4 , 30g / L; KCN, 30g...

Embodiment 3

[0031] The LY12 aluminum alloy plate with a thickness of 0.3mm is punched out of the reaction gas channel and the inlet and outlet channels of hydrogen, air and cooling water. Dip in a 70°C NaOH solution with a mass ratio of 20% for 30s to remove the oxide film on the surface of the aluminum alloy; then use a volume ratio of 20% HNO 3 The solution was washed for 10s to remove the floating ash on the surface. Then carry out anodic oxidation in a sulfuric acid solution with a volume ratio of 30%, the temperature is 10°C, and the current density is 1.5A / dm 2 , the time is 30min; then coat bisphenol A epoxy resin on the oxide film, and heat at 220°C for 6 hours to cure the resin.

[0032] Use black electroplating protective paint to coat the entire area of the bipolar plate with flow channels, then heat it in an oven at 60°C for 30min, take it out, and cool it to room temperature. Use 2000# sandpaper to polish off the electroplating protective paint and passivation layer on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com