Doctor blade system for a printing unit, intended for an intaglio printing machine

A printing unit and squeegee technology, applied in gravure rotary printing presses, printing presses, rotary printing presses, etc., can solve problems such as restricting the movement of the squeegee blade bracket

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

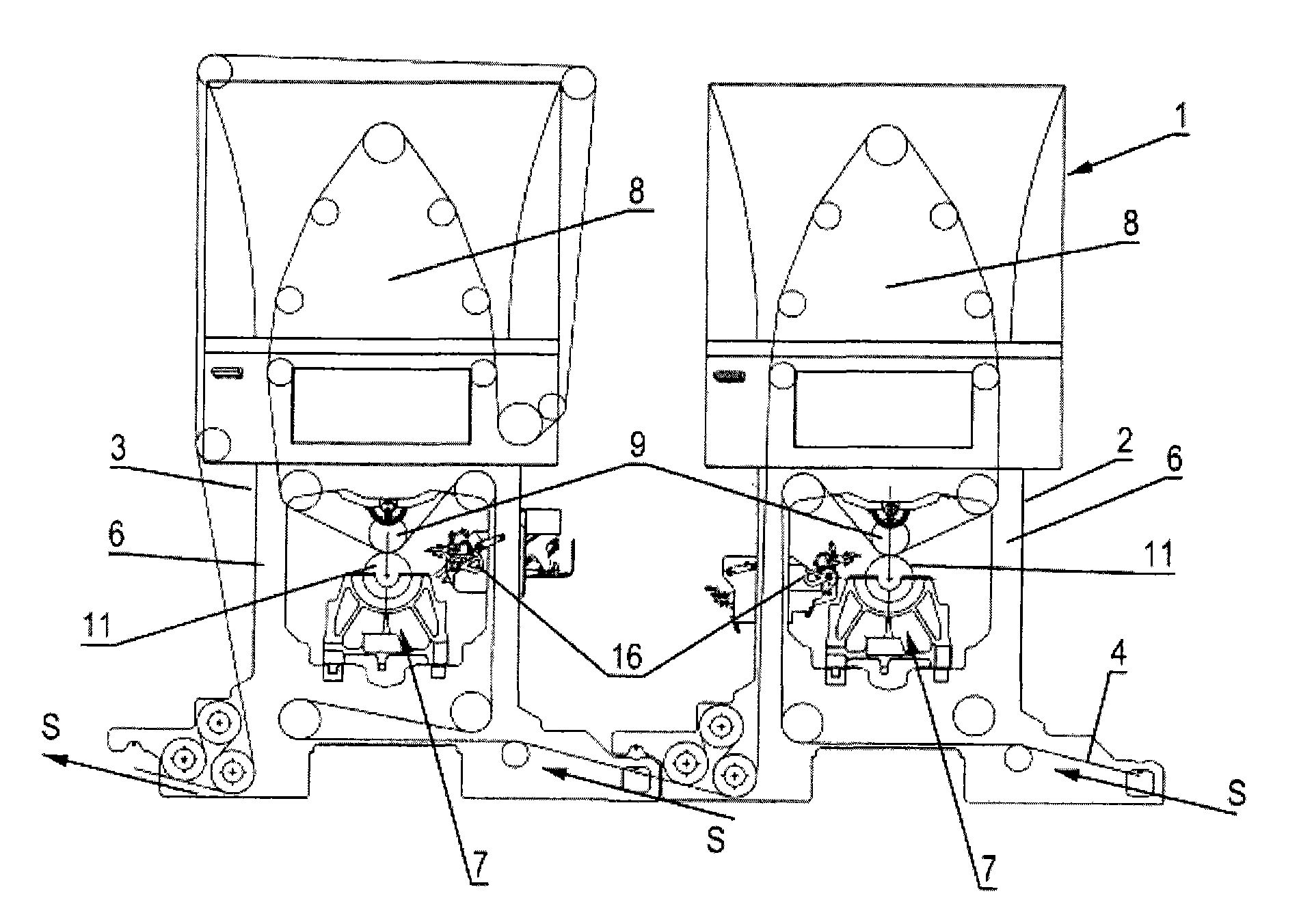

[0048] Such as figure 1 As shown, the gravure printing machine (1) consists of a plurality of printing units (2 and 3) mounted in succession one after the other (here only two units are drawn). Print media (4) from upstream ( figure 1 Arrow S in ) enters the first printing unit (2), will be printed with the first color, leaves this unit downstream (S), and then enters (S) the second printing unit (3) upstream, will be printed with The second color, and exits (S) the unit downstream. The print medium (4) can enter and exit as many printing units as required, producing different color prints.

[0049] Each printing unit (2 and 3) comprises a frame (6), a printing carriage (7) inserted in the center of said frame (6), a dryer (8), a pinch roller (9) and A pump (not shown) for feeding ink. Due to the mechanism for transporting the print medium (4), the first printing unit (2) produces a front side print and the second unit unit (3) produces a back side print on the same print ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com