Integrated downdraft flexible wire feeder

A wire feeder and flexible technology, applied in the field of integrated downdraft flexible wire feeders, can solve the problems of obvious layering of tobacco shreds, many transmission parts, and high breaking rate, and achieve the improvement of cigarette quality, good sealing effect, and weight. light effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

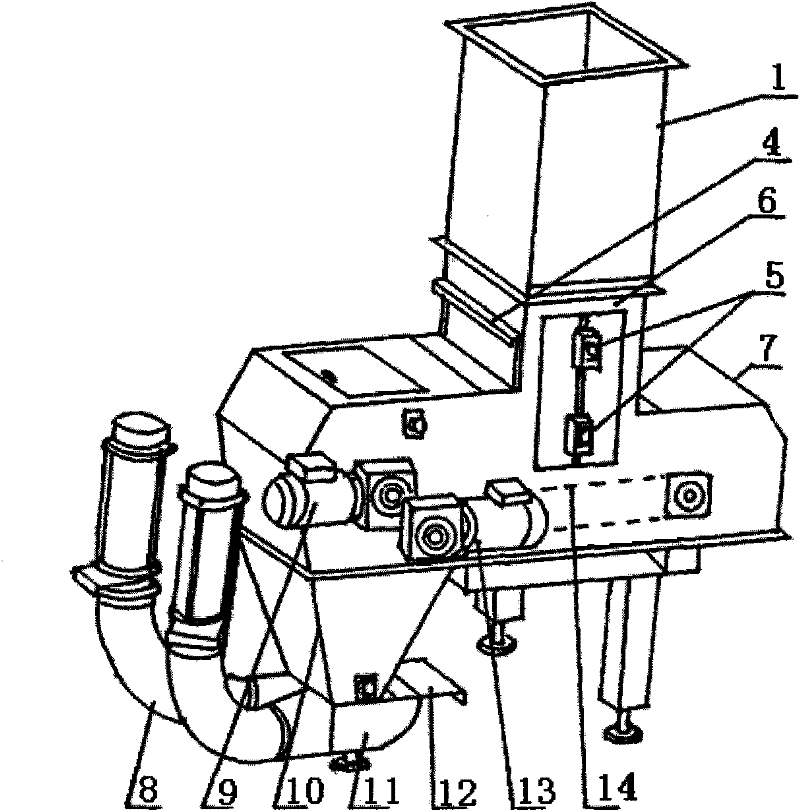

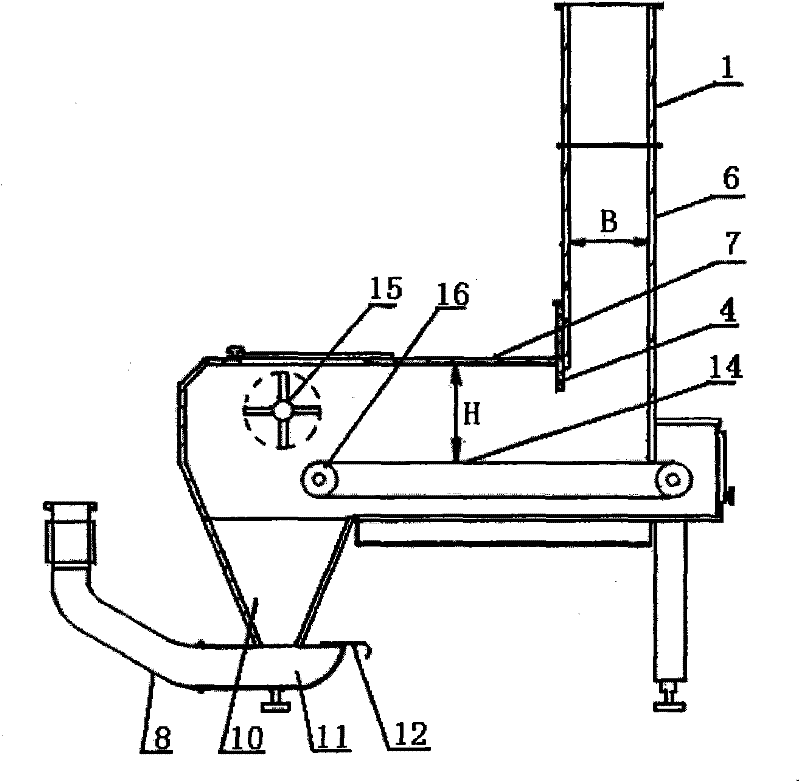

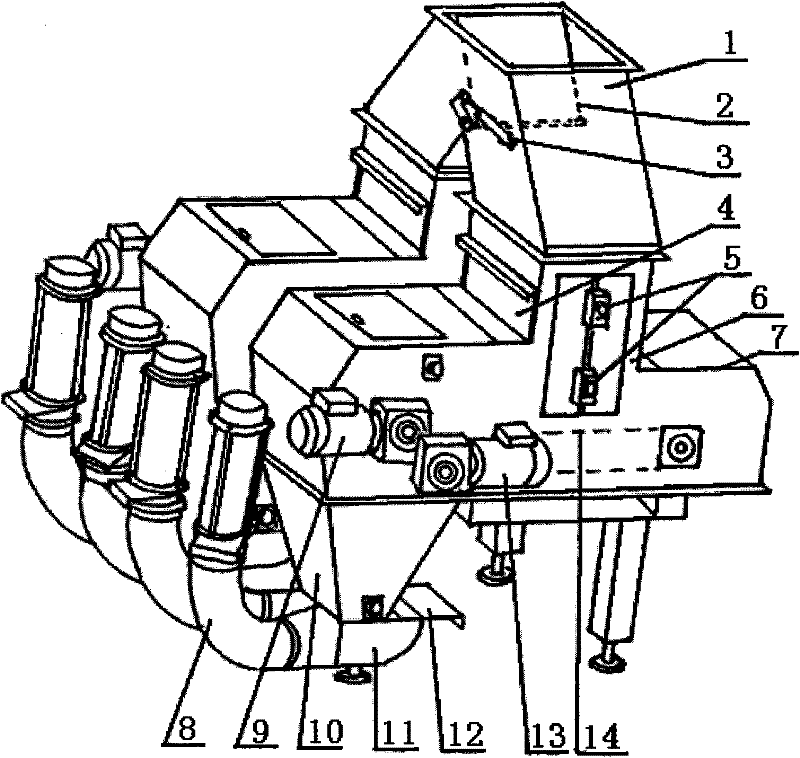

[0024] Further illustrate the present invention below in conjunction with accompanying drawing.

[0025] Such as figure 1 , figure 2 As shown, the integrated down-suction flexible wire feeder of the present invention includes a cabinet 7, a wire suction pipe 8, a feeding pipe 1, a metering pipe 6, a feeding device, a material leveling device, a falling hopper 10 and an industrial computer (not shown in the figure). shown), the feeding device and the homogenizing device are arranged in the cabinet 7, the homogenizing device is arranged above the end of the feeding device, the feeding device includes a conveyor belt 14 and a transmission motor 13, and the lower end of the metering tube 6 is arranged at the beginning of the conveyor belt 14 Above, the hopper 10 is arranged at the end of the conveyor belt 14, and the conveying motor 13 is controlled by an industrial computer; the leveling device includes a rake roller 15 and a rake roller motor 9, and the rake roller 15 is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com