Circulating fruit and vegetable drying box with heat exchange device

A heat exchange device, a circulating technology, applied in food processing, food science, applications, etc., can solve the problems of excessive dryness or excessive humidity, uneven product, low heat exchange efficiency, etc., so as to reduce processing costs and shorten transportation distance. , uniform effect of drying products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

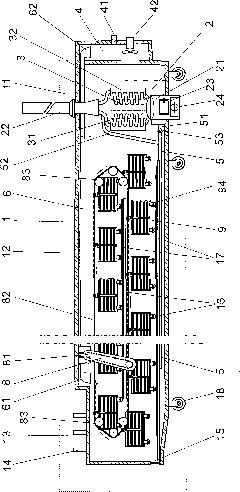

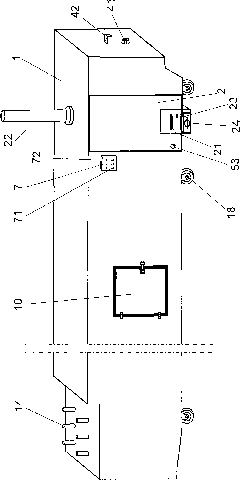

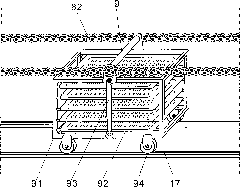

[0019] Below in conjunction with accompanying drawing, structural principle of the present invention will be further described:

[0020] The present invention is achieved in this way. A circulating fruit and vegetable drying box with a heat exchange device includes a long box body 1, and the box body 1 can be divided into a heating area 11, a high-temperature drying area 12 and a low-temperature dehumidification area. 13. A combustion furnace 2 is installed in the heating area 11. The combustion furnace 2 is composed of a combustion chamber 21 and a chimney 22 protruding out of the box; the combustion furnace 2 is a firewood type combustion furnace, and a furnace door is opened on the front of the combustion chamber 21 23, the air intake adjustment door 24 is arranged below; the heat exchange device 3 is arranged above the combustion chamber 21, and the heat exchange device 3 is composed of multiple sets of spiral heat exchange tubes 31, and the outer surface of the heat exchan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com