Water vortex splashing and filtering device

A filter device and water swirl technology, which is applied in combined devices, suction filters, and dispersed particle separation, can solve problems such as poor gas filtration effect, and achieve the effects of enhanced capture ability, strong fusion ability, and strong capture ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

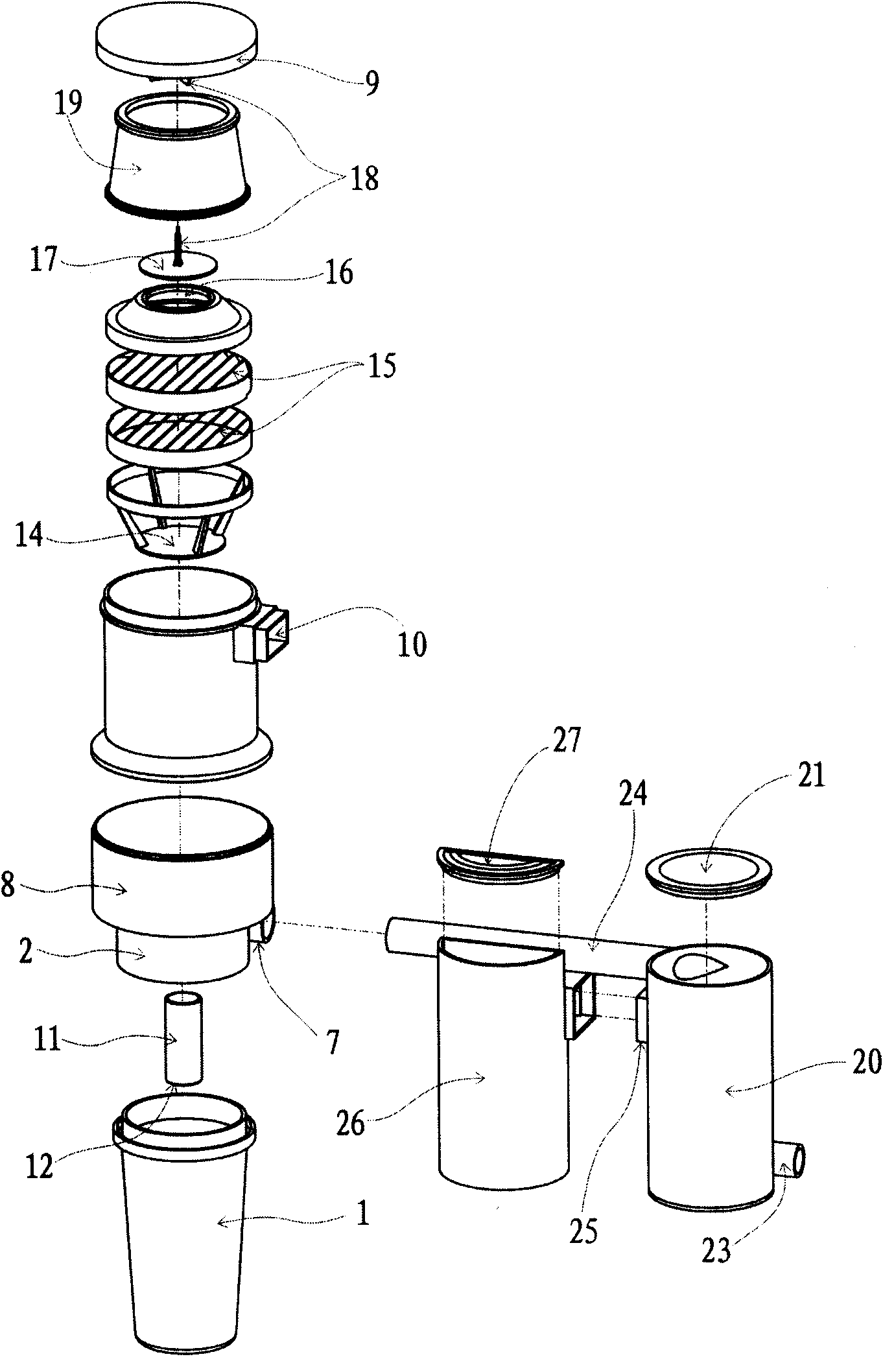

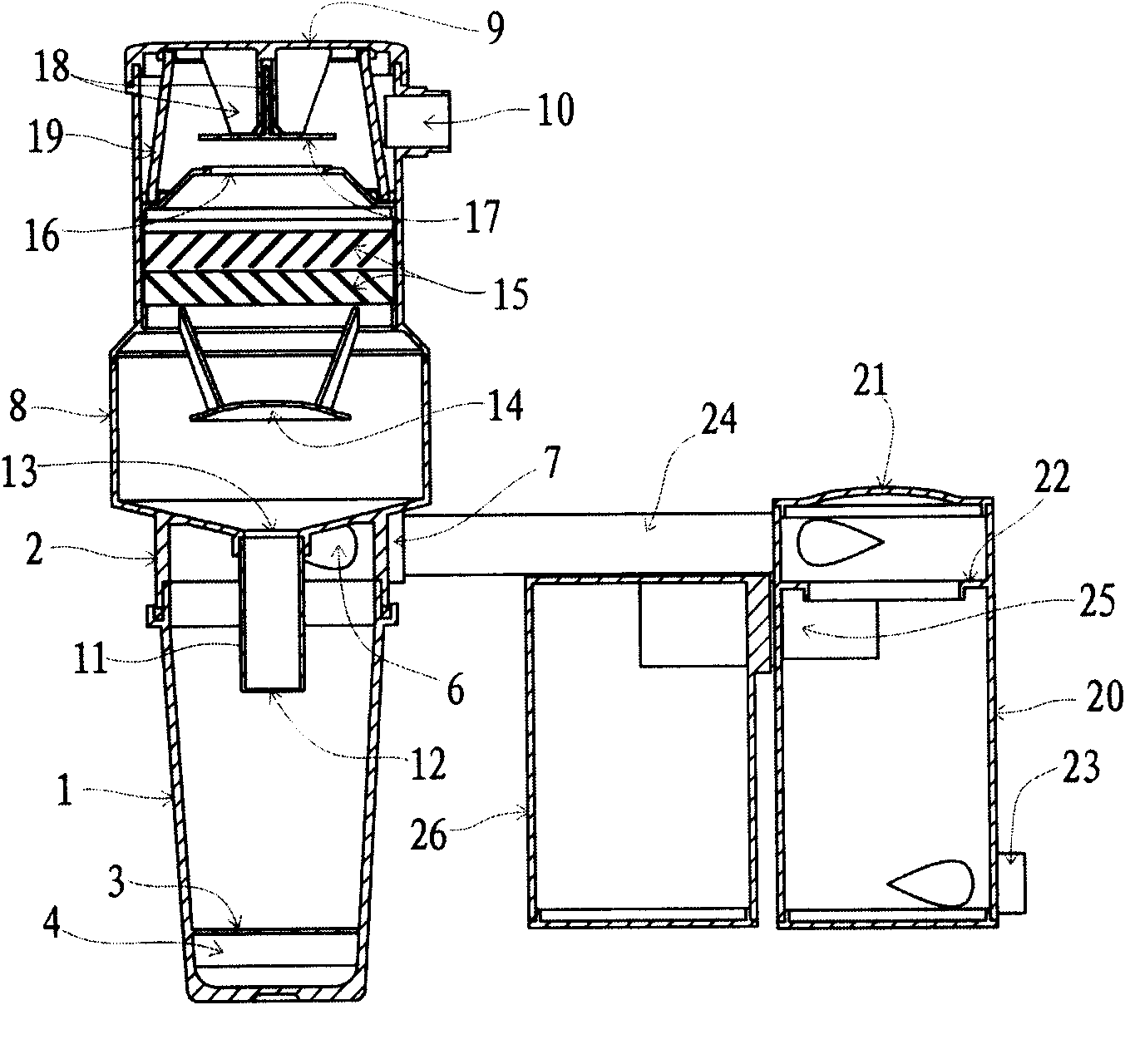

[0038]Embodiments of the present invention are as figure 1 , figure 2 As shown, it includes coarse filter device, air intake pipe (7), water swirl filter part, suction air pipe (11), splash filter part, splash baffle (14), splash-proof component, moisture-proof device, protective net cover; the water whirl filter part is composed of the water whirl chamber (1) and the water whirl chamber upper cover (2), and the lower part of the water whirl chamber (1) is provided with an annular isolation plate (3) ), a deposition chamber (4) is formed between the ring-shaped separating plate (3) and the bottom of the hydrovortex chamber (1), and the side wall of the hydrovortex chamber loam cake (2) is provided with a gas cutout (6), and the gas cutout The inlet (6) is connected with an air inlet pipe (7); the splash filter part is composed of a splash chamber (8) and a splash chamber upper cover (9), and the splash chamber upper cover is placed on the side wall of the splash chamber (8)....

Embodiment 2

[0053] The second embodiment of the present invention is as image 3As shown, it includes an air inlet pipe (7), a water swirl filter part, a suction air duct (11), a splash filter part, a splash baffle (14), and a splash prevention member; ) and the water swirl chamber upper cover (2), the bottom of the water swirl chamber (1) is provided with an annular isolation plate (3) connected to the side wall of the water swirl chamber (1), the annular isolation plate (3) and the water swirl A deposition chamber (4) is formed between the bottoms of the chamber (1), the diameter of the deposition chamber (4) is greater than the diameter of the annular separation plate (3), and the side wall of the hydrovortex chamber loam cake (2) is provided with a gas cutout (6 ), the gas inlet (6) is connected with the air inlet pipe (7); the splash filter part is composed of the splash chamber (8) and the splash chamber upper cover (9), and is above the splash chamber upper cover (9) An air outlet...

Embodiment 3

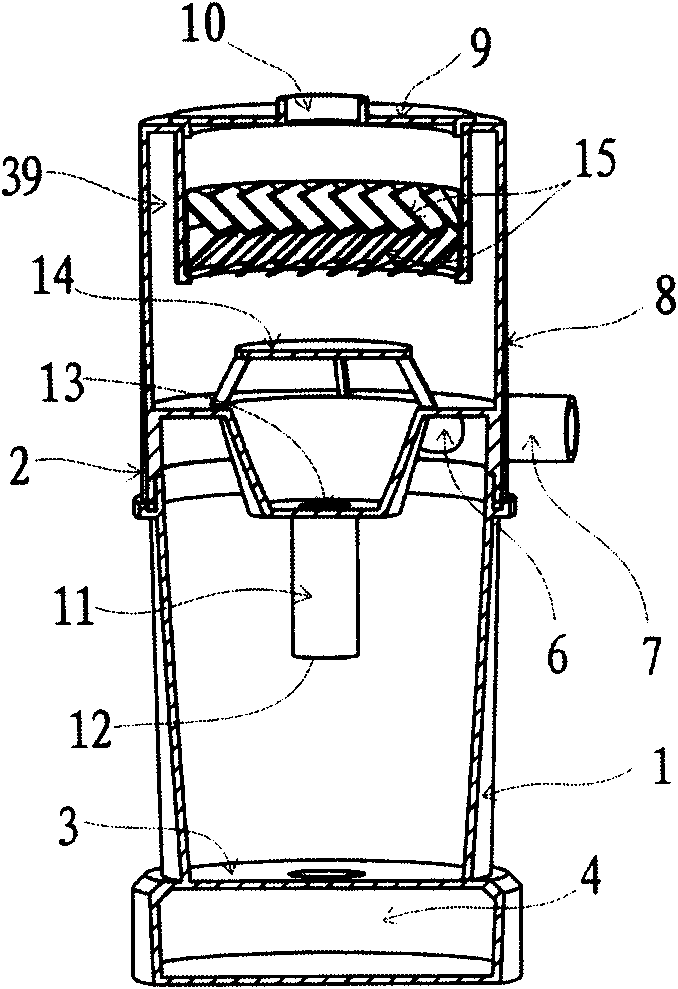

[0057] The third embodiment of the present invention is as Figure 4 As shown, it includes an air inlet pipe (7), a water swirl filter part, a suction air duct (11), a splash filter part, a splash baffle (14), and a splash prevention member; ) and the water swirl chamber upper cover (2), the side wall of the water swirl chamber upper cover (2) is provided with a gas incision (6), and the gas incision (6) is connected with an air inlet pipe (7); the splash The filter part is composed of a splash chamber (8) and a splash chamber upper cover (9), and an air outlet (10) is arranged above the splash chamber upper cover (9); the bottom of the splash chamber (8) is formed by a water swirl chamber The center of the upper cover (2) sinks into the water swirl chamber (1), and one end of the suction air pipe (11) passes through the center of the bottom of the splash chamber (8) and extends into the swirl chamber (1) to form a port One (12), the other end forms port two (13) at the cente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com