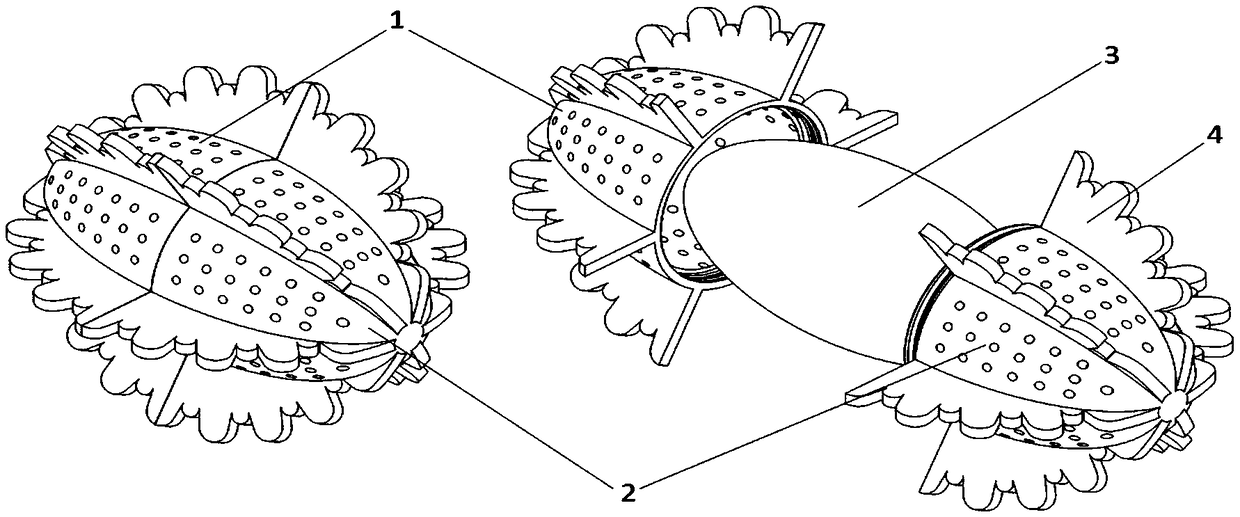

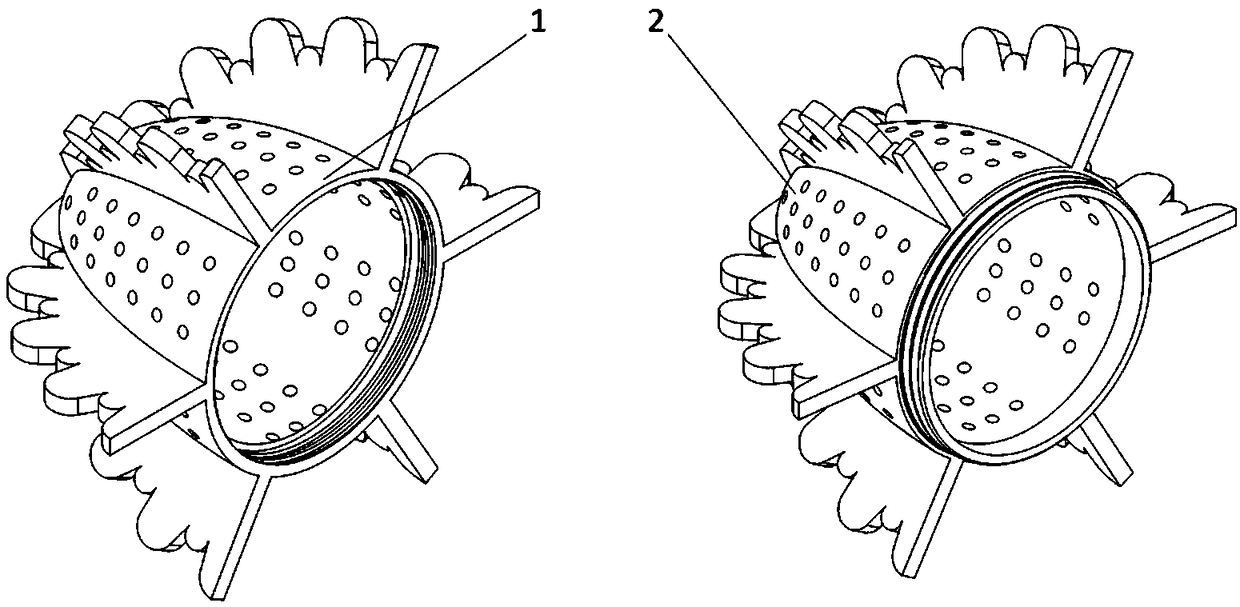

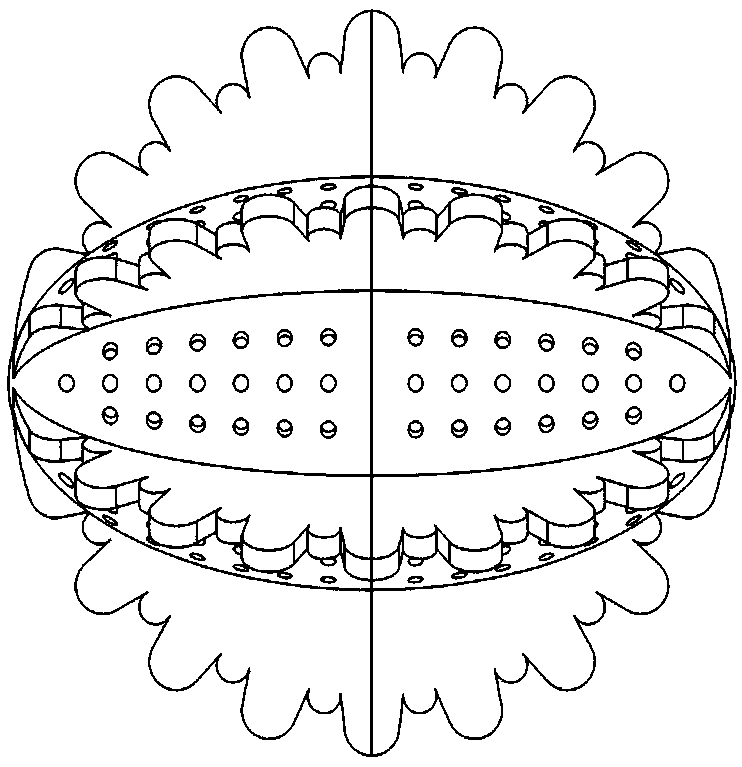

Anti-winding clothes washing roller with sterilizing effect

A sterilization and anti-entanglement technology, applied in the field of anti-entanglement laundry rollers, can solve the problems of loss of function, damage to the handle, easy entanglement of clothes, etc., to achieve strong sterilization and cleaning power, increase contact area, and improve cleaning. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] In terms of parts by mass, a raw material formula of a bactericidal anti-winding laundry roller is composed as follows:

[0061] Silicone rubber (methyl vinyl silicone rubber, MVQ, grade: KE-571-U,

[0062] Shin-Etsu Silicone International Trading Co., Ltd.) 75 copies

[0063] Inorganic non-metallic nanomaterials (nanometer silicon dioxide, H10, Jiangsu Tianxing New Material Co., Ltd.,

[0064] Particle size: 20nm) 3 parts

[0065] Vulcanizing agent (dicumyl peroxide DCP, chemically pure, Sinopharm Chemical Reagent Co., Ltd.) 5 parts

[0066] Catalyst (stannous octoate, analytically pure, Shanghai Puzhen Biotechnology Co., Ltd.) 2 parts

[0067] Dispersant (acetone, analytically pure, Shanghai Debang Chemical Co., Ltd.) 5 parts

[0068]Surfactant (cationic silicone oil, F-557, Guangzhou Feirui Chemical Co., Ltd.) 5 parts

[0069] Surface treatment agent (silane coupling agent KH-460, Suzhou Patna Chemical Co., Ltd.) 5 parts

[0070] During preparation, silicone ru...

Embodiment 2

[0072] The difference from Example 1 is that nano-titanium dioxide is used as the inorganic non-metal nanomaterial in the raw material formula of this example. Compared with nano-silicon dioxide, nano-titanium dioxide also generates hydroxyl radicals under photocatalysis, and its bactericidal ability is stronger. Strong, so that the sterilization effect of the washing roller is better; and other types of catalysts and surface treatment agents and different ratios are selected.

[0073] In terms of parts by mass, a raw material formula of a bactericidal anti-winding laundry roller is composed as follows:

[0074] Silicone rubber (methyl vinyl silicone rubber, MVQ, grade: KE-571-U,

[0075] Shin-Etsu Silicone International Trading Co., Ltd.) 74 copies

[0076] Inorganic non-metallic nanomaterials (nano-titanium dioxide, DK405, Beijing Deke Daojin Technology Co., Ltd.,

[0077] Particle size: 35nm) 4 parts

[0078] Vulcanizing agent (dicumyl peroxide DCP, chemically pure, Sino...

Embodiment 3

[0085] The difference from Example 1 is that in the raw material formula of this example, nano-zinc oxide is used as the inorganic non-metallic nanomaterial, and other types of vulcanizing agents, catalysts, surface treatment agents and different proportions are selected.

[0086] In terms of parts by mass, the raw material formula of a anti-winding laundry roller with bactericidal effect is as follows:

[0087] Silicone rubber (methyl vinyl silicone rubber, MVQ, grade: KE-571-U,

[0088] Shin-Etsu Silicone International Trading Co., Ltd.) 75 copies

[0089] Inorganic non-metallic nanomaterials (nanometer zinc oxide, DK404, Beijing Deke Daojin Technology Co., Ltd.,

[0090] Particle size: 30nm) 3 parts

[0091] Vulcanizing agent (sulfur, industrial grade, Sinopec Beijing Yanshan Chemical Co., Ltd.) 5 parts

[0092] Catalyst (stannous octoate, analytically pure, Shanghai Puzhen Biotechnology Co., Ltd.) 2 parts

[0093] Dispersant (acetone, analytically pure, Shanghai Debang...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com