Processing machine

A processing device and control device technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as workability deterioration, expansion of processing device installation space, and difficulty for operators to access the processing area, etc. The effect of omitting the safety barrier and reducing the installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

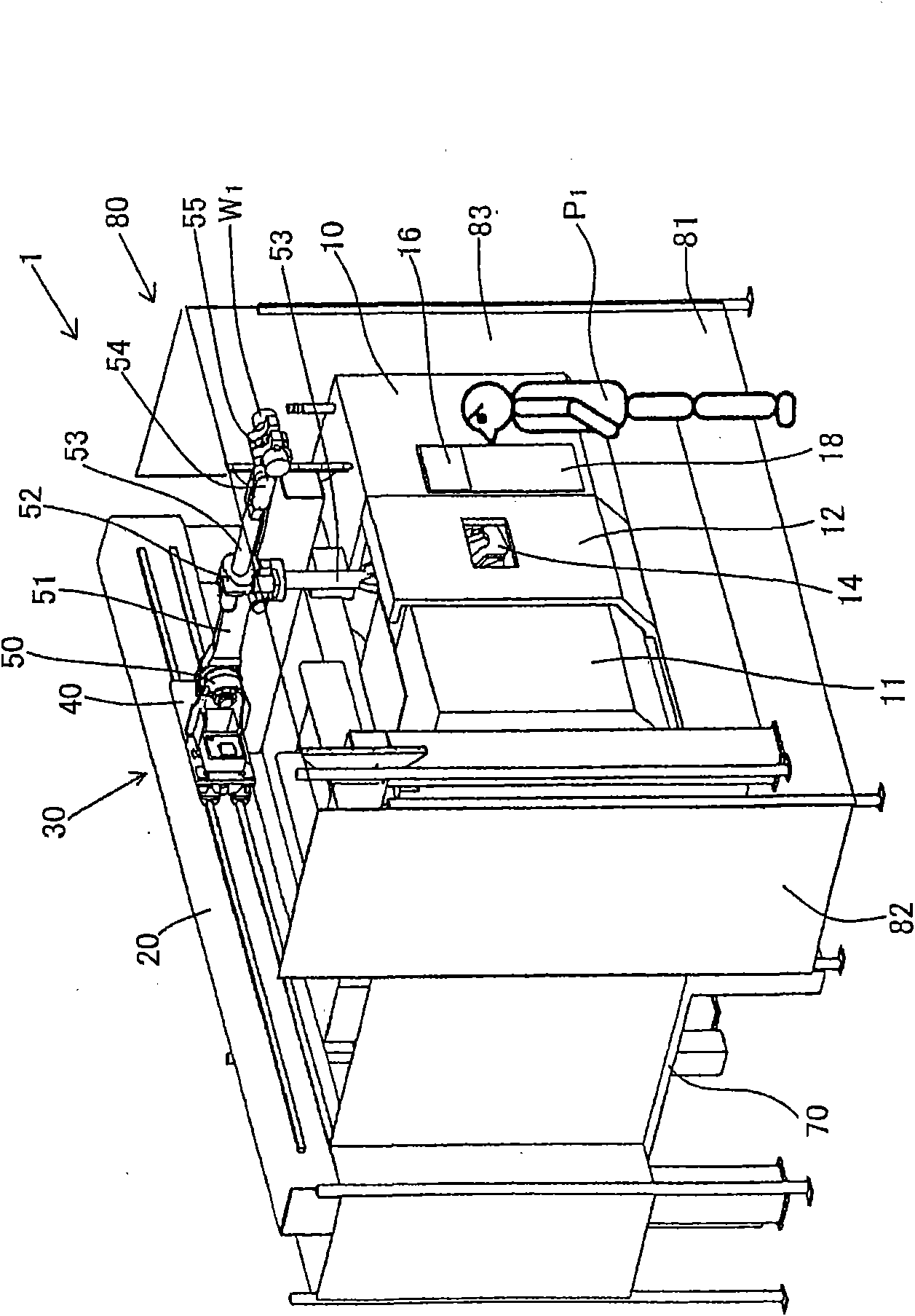

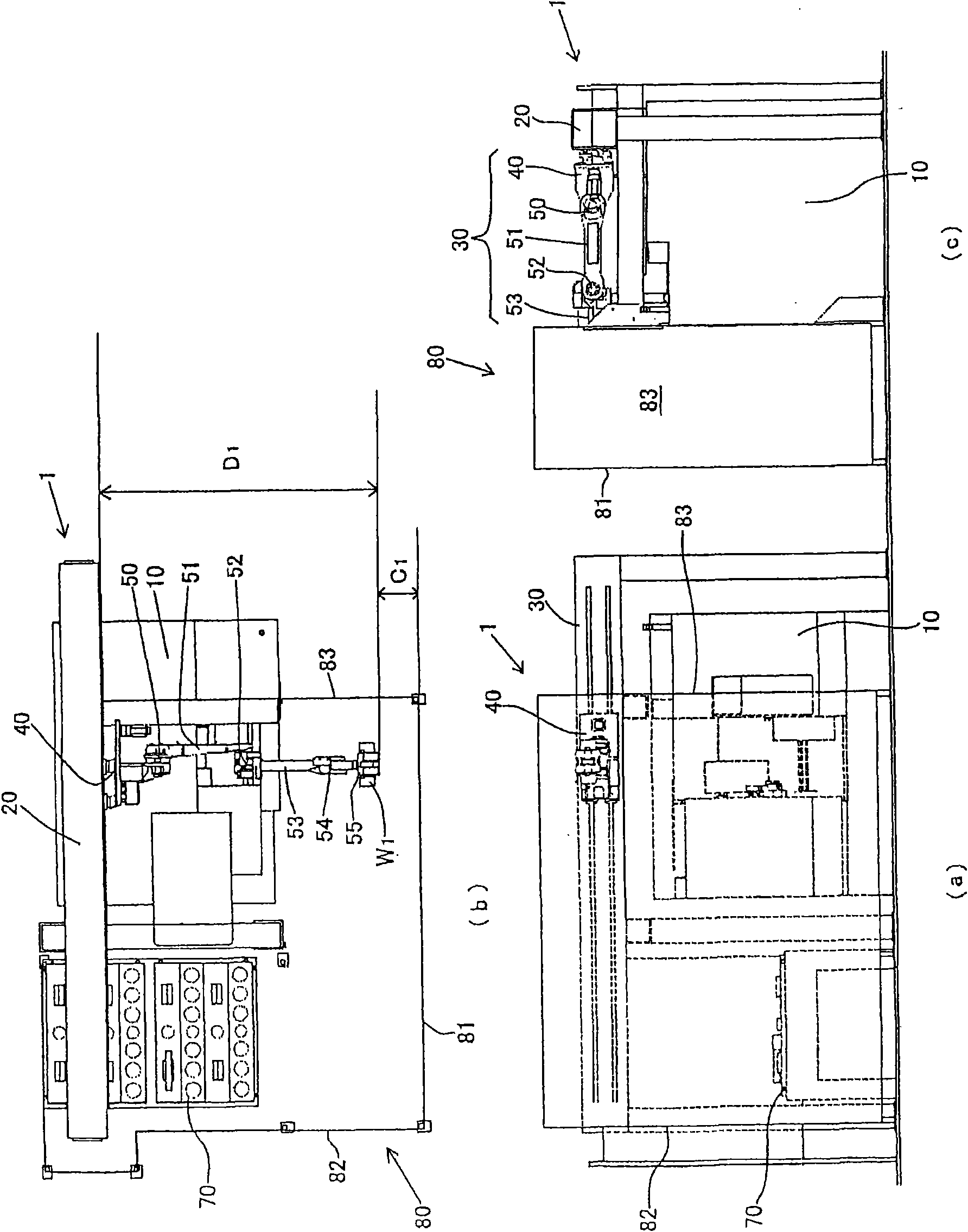

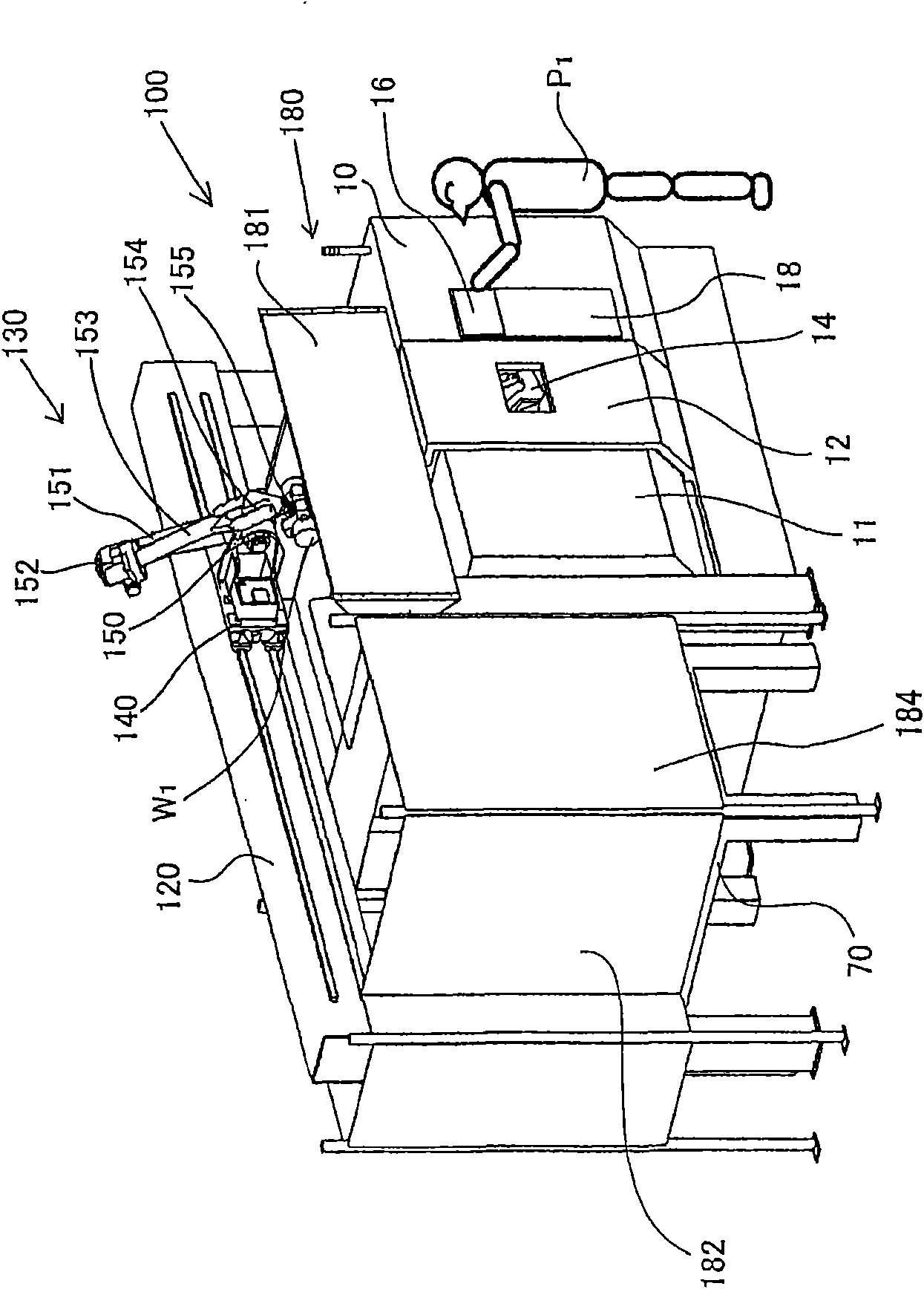

[0038] figure 1 It is an external view showing a processing device combining a machine tool and an articulated robot, figure 2 It is a three-sided map.

[0039] The overall processing device denoted by reference numeral 1 includes: a machine tool 10 ; an articulated robot 30 traveling on a gantry rail 20 arranged above the machine tool 10 ; and an NC control device.

[0040] The machine tool is, for example, a lathe-type machining center, and has a workpiece supply and discharge tray 70 provided on the side of the machine tool. The gantry rail 20 covers the machine tool 10 and the pallet 70 .

[0041] The articulated robot 30 traveling on the gantry rail 20 has a robot base 40 having a first arm 51 connected via a first joint 50 . The first arm 51 has a second arm 53 connected via a second joint 52 , and a robot hand 55 is attached to the tip of the second arm 53 via a third joint 54 . Manipulator 55 holds workpiece W 1 It is supplied and discharged to the machine tool 1...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap