Collapsible cargo trailer and method of distribution

a cargo trailer and collapsible technology, applied in the field of cargo trailers, can solve the problems of inefficiency in the process used to manufacture and distribute such trailers, and achieve the effect of reducing the space required and reducing the shipping cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

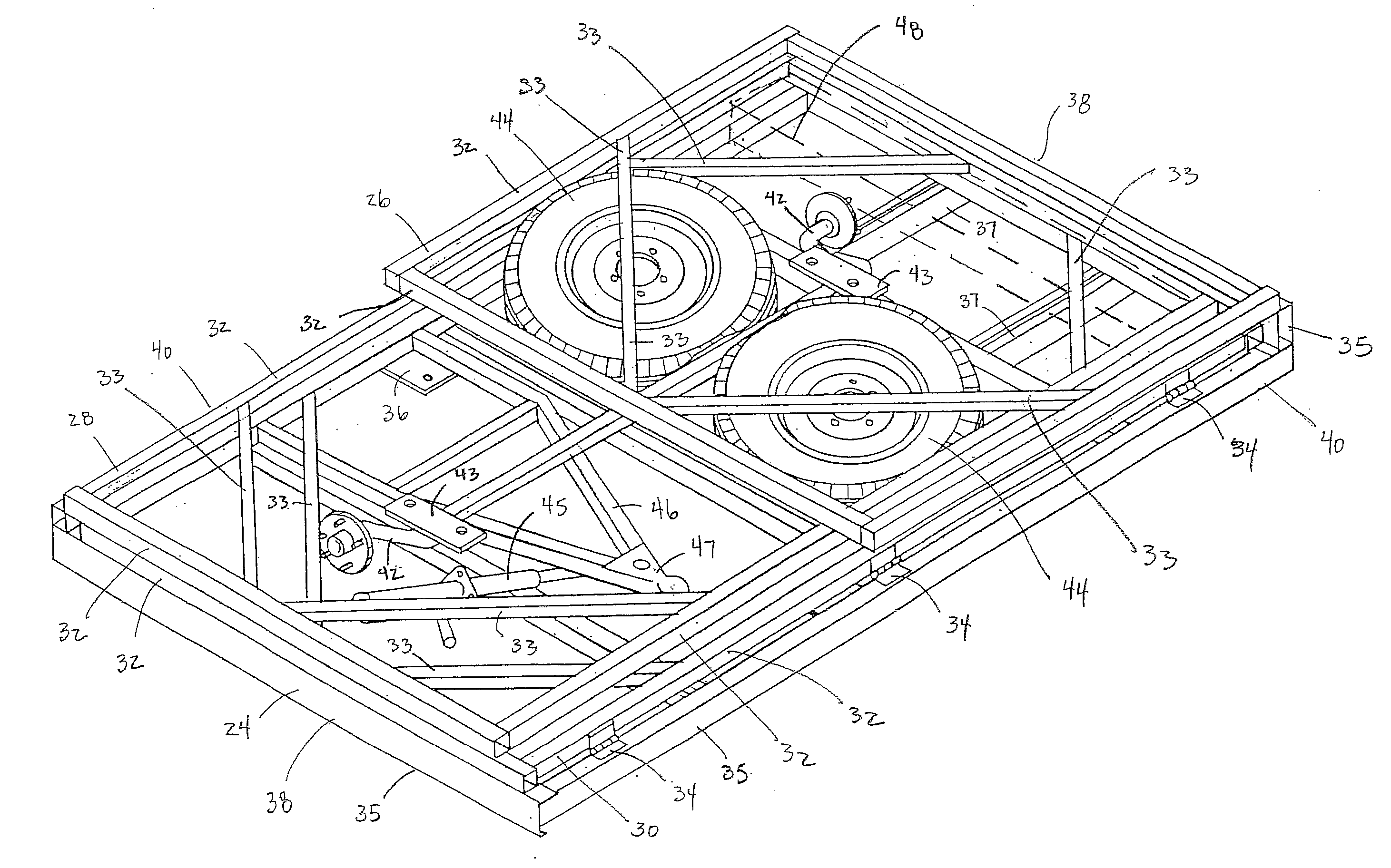

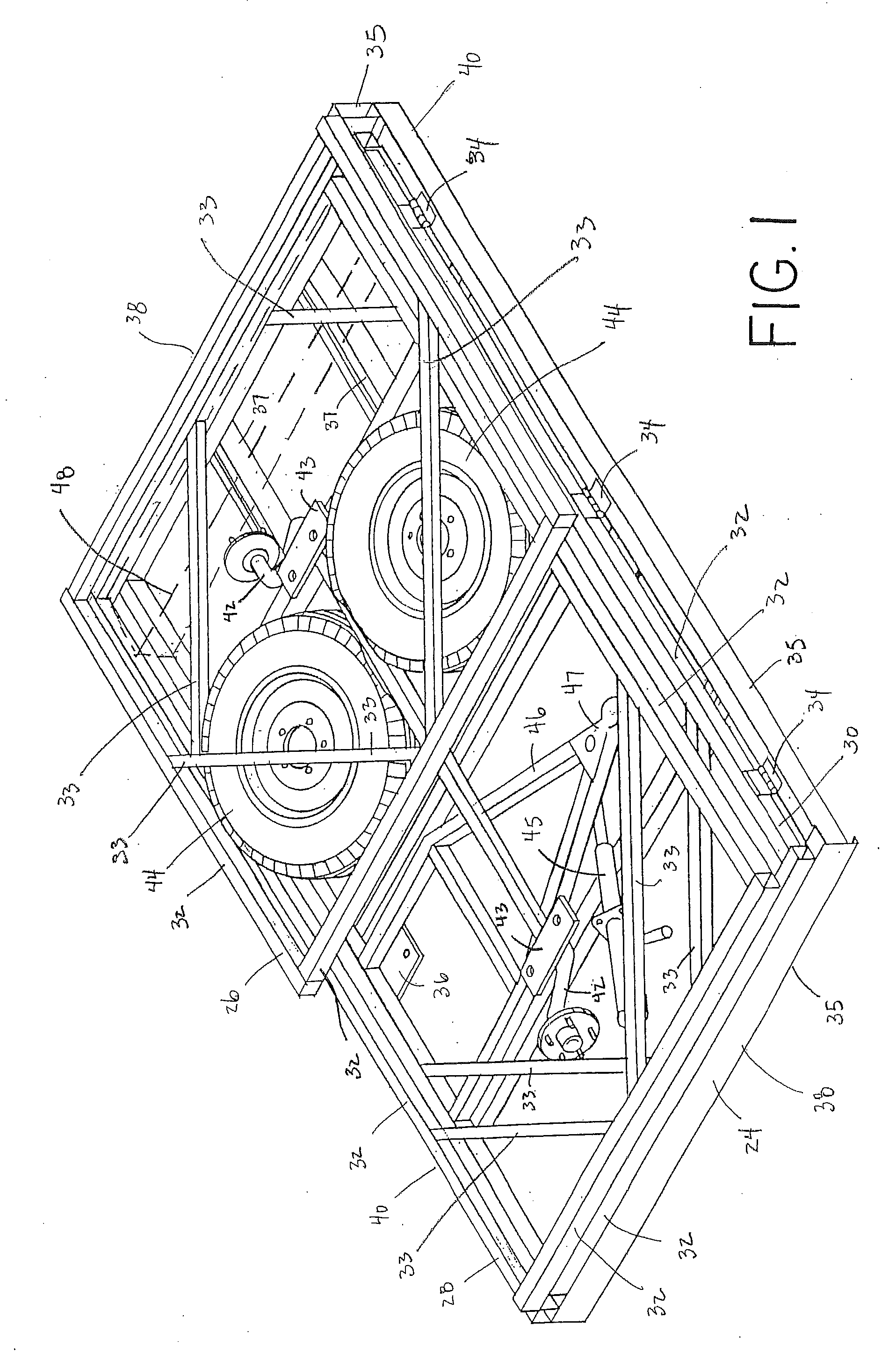

[0024] A cargo trailer 20 in accordance with the present invention is shown in FIG. 7. The cargo trailer includes a frame assembly 22 that can be collapsed to facilitate the shipping of cargo trailer 20 prior to the final assembly of cargo trailer 20.

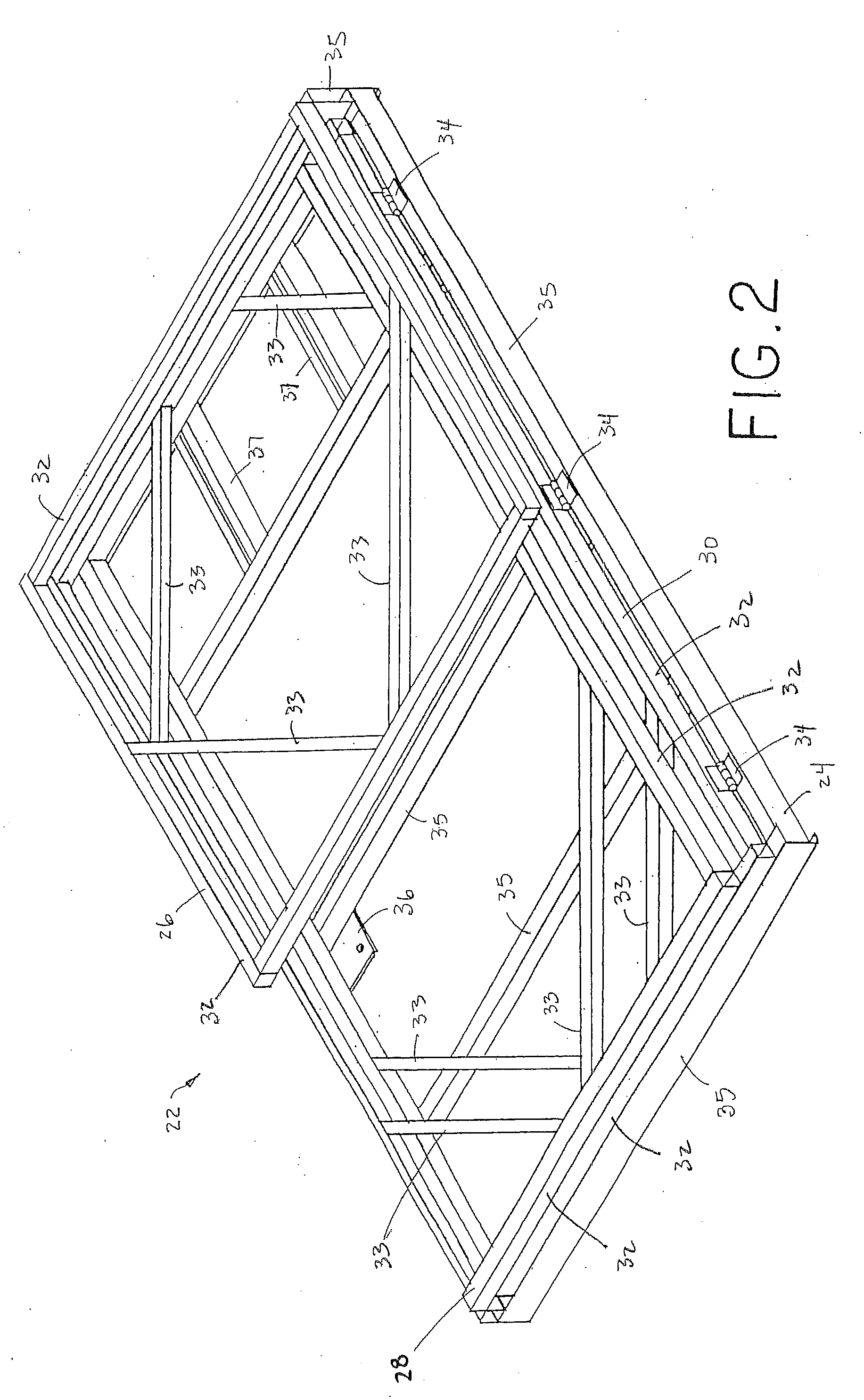

[0025] Frame assembly 22 is best seen in FIGS. 1-5 and includes a floor structure 24, an end frame 26, a first side frame 28, and a second side frame 30. Each of these frames 26, 28 and 30, are wall structures that include a plurality of structural members 32, 33 secured together in an open framework. Outer perimeter members 32 are braced by members 33. Structural members 32 and bracing members 33 are elongate square or box tube steel members that are secured together by welding. Bolts or other suitable method may also be used to secure members 32 together to form frames 26, 28, 30.

[0026] Floor structure 24 has a frame defined by structural steel members 35. Axle brackets 36 and hitch reinforcement members 37 are secured to structural...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap