Ammonia-soda coupled oven gas desulfurization process

A desulfurization process and coke oven gas technology, which is applied in the petroleum industry, combustible gas purification, sulfur preparation/purification, etc., can solve the problems of backward process, poor desulfurization effect, and inability to meet environmental protection, and achieve good desulfurization effect and operating costs. The effect of low and good promotion and use value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

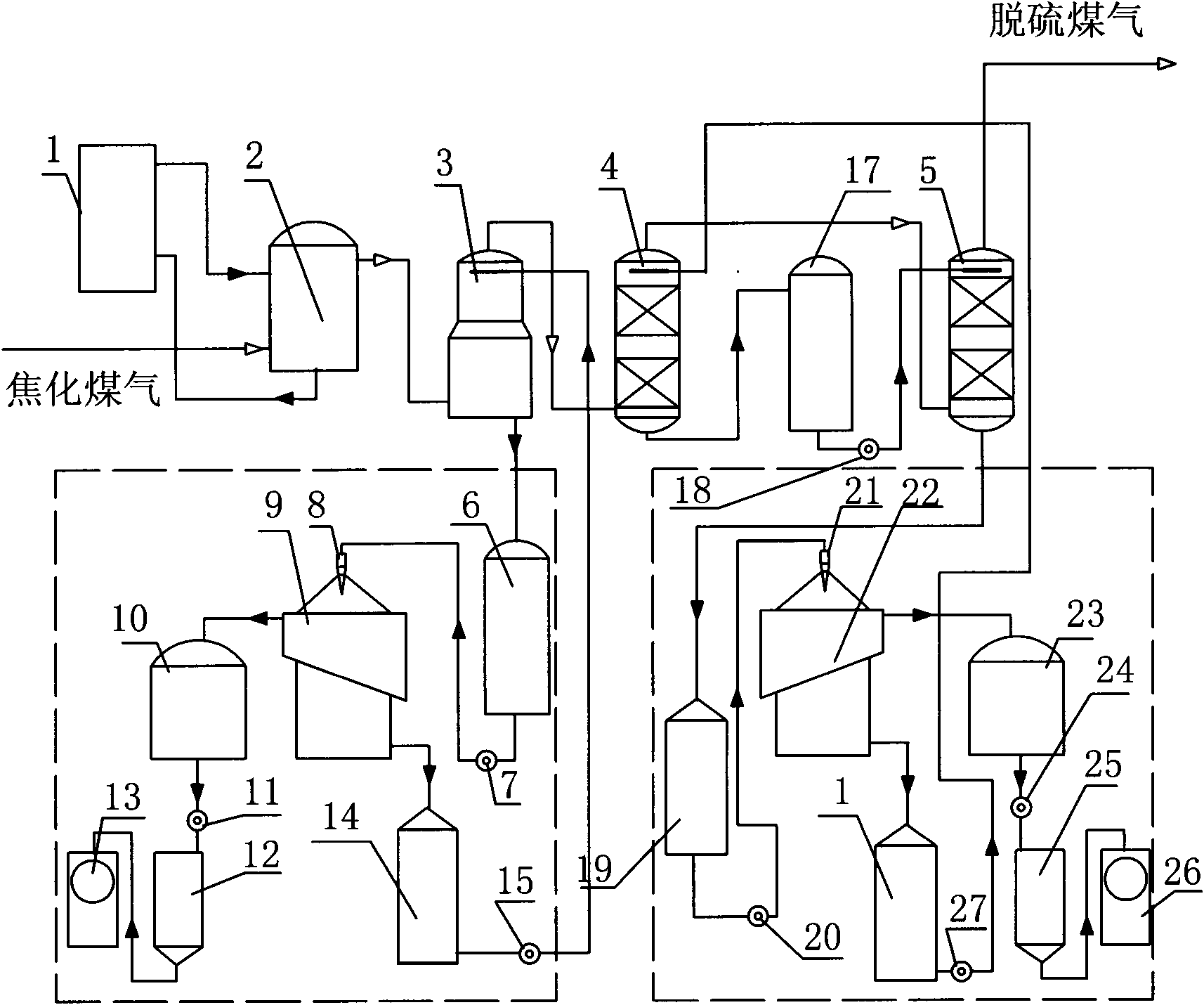

[0010] The desulfurization process of the present invention will be described in detail below with reference to the accompanying drawings.

[0011] The ammonia-soda combined coke oven gas desulfurization process of the present invention is to send the coke oven gas from the coking process into the precooling tower 2 and indirectly cool the refrigerated liquid from the refrigerator 1 in the precooling tower 2, and pass through the precooling tower 2 The pre-cooled coke oven gas is blown into the turbulent ball tower 3 with ammonia water as the absorbent for reaction and absorption. The ammonia water is sprayed from the top of the turbulent ball tower 3, discharged from the bottom of the turbulent ball tower 3, and sent to the rich liquid tank 6. The oxidation regeneration pump 7 is sent to the jet injector 8 on the top of the ammonia oxidation regeneration tank 9, and the jet is sprayed into the oxidation regeneration tank 9 after adding oxygen to generate sulfur foam, and the s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap