Clamping tire type automobile carrier of three-dimensional garage

The technology of a car transporter and a three-dimensional garage is applied in the field of parking equipment, which can solve the problems of increasing the access time of the car, unable to realize the direct access to the car, etc., and achieves the effect of short access time and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

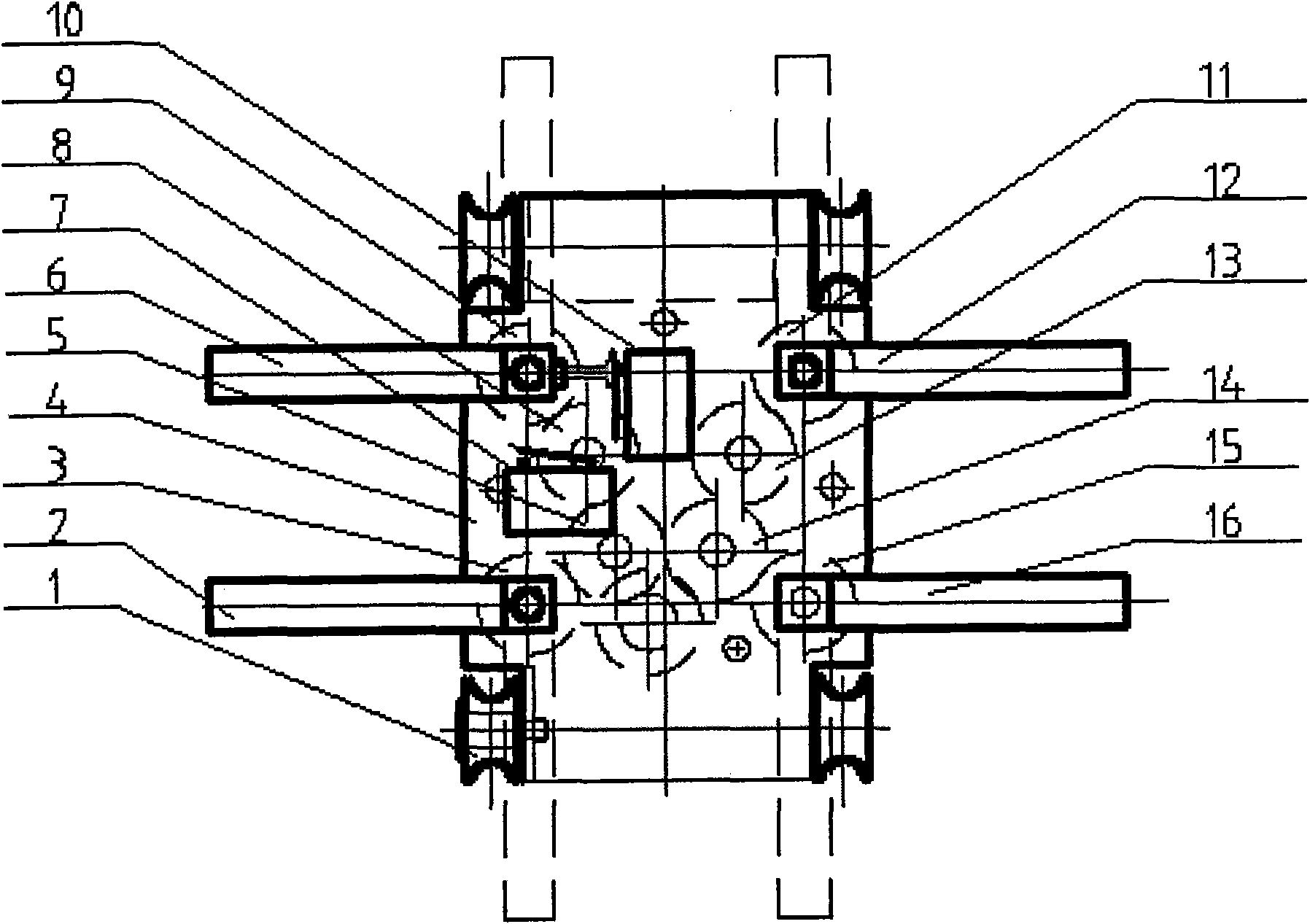

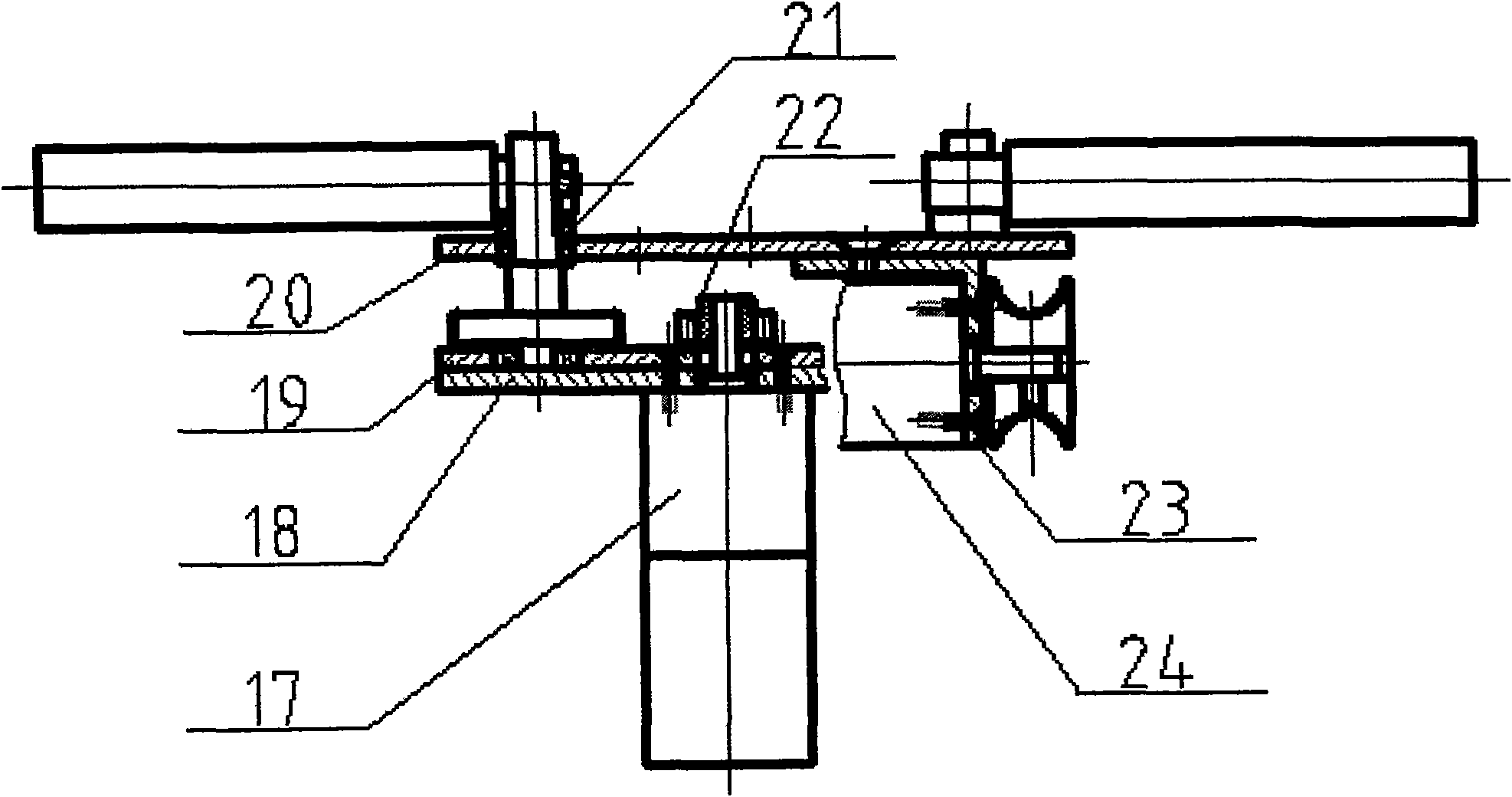

[0013] figure 1 , figure 2 Among them, underframe 4 is made up of upper fixed plate 20, lower fixed plate 19 and backing plate 18. Four traveling wheels 1 are installed in the appropriate positions of four corners below the fixed plate 20 on the underframe, adopt diagonal drive, and the traveling motor 24 is fixed on the side plate 23 of the underframe. The clamping mechanism adopts a left-right symmetrical arrangement, the clamping mechanism motor 17 is installed on the fixed plate 19 and the backing plate 18 under the chassis, the driving wheel 22 is connected with the clamping mechanism motor 17 through a coupling, and the two ends of the four intermediate wheel shafts are respectively fixed On the lower fixed plate 19 and the upper fixed plate 20 of the underframe, one end of the four gear shafts is installed on the lower fixed plate 19 of the underframe through rolling bearings, and the other end is installed on the upper fixed plate 20 through the guide sleeve 21 and e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com