Novel double-wall granary

A new type of granary technology, applied in the field of large-scale granaries, can solve the problems of no heat preservation performance, cumbersome production procedures, poor structural stability, etc., and achieve the effect of ensuring grain quality, good overall rigidity and strong bearing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

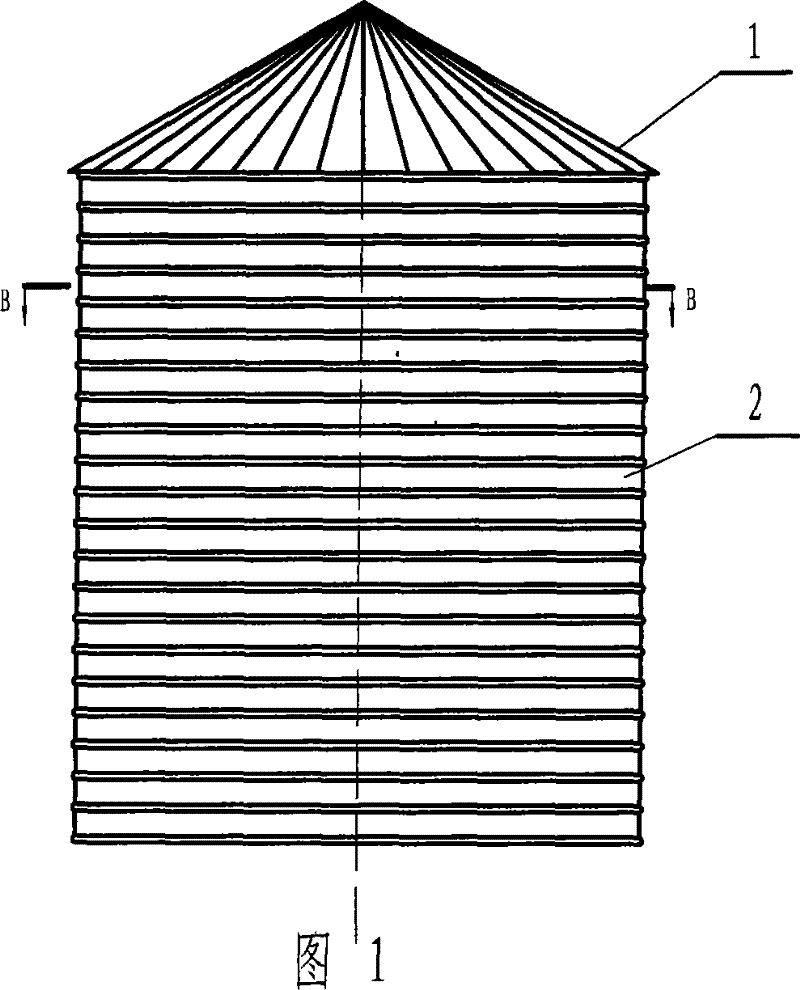

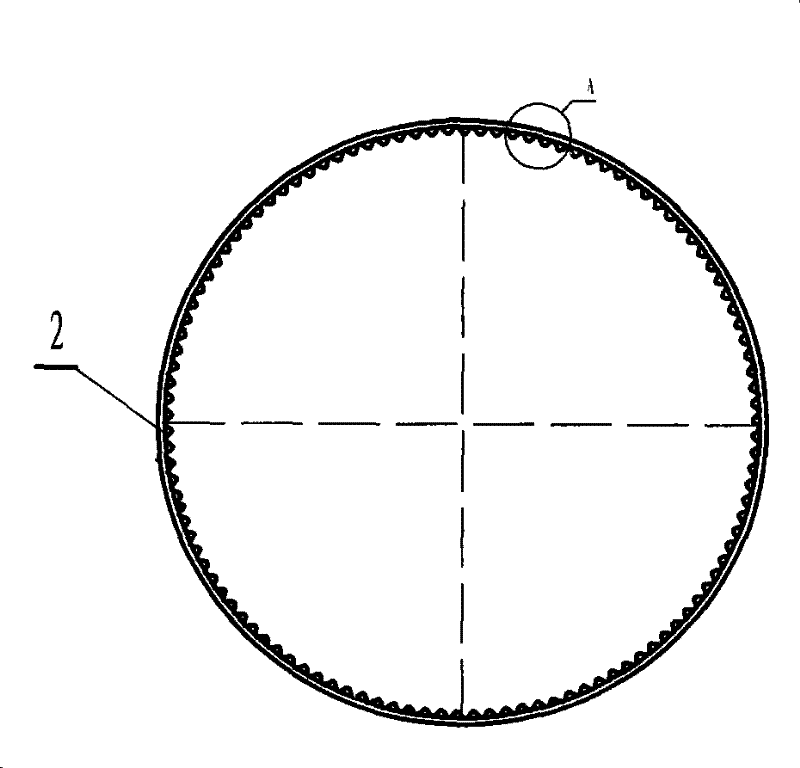

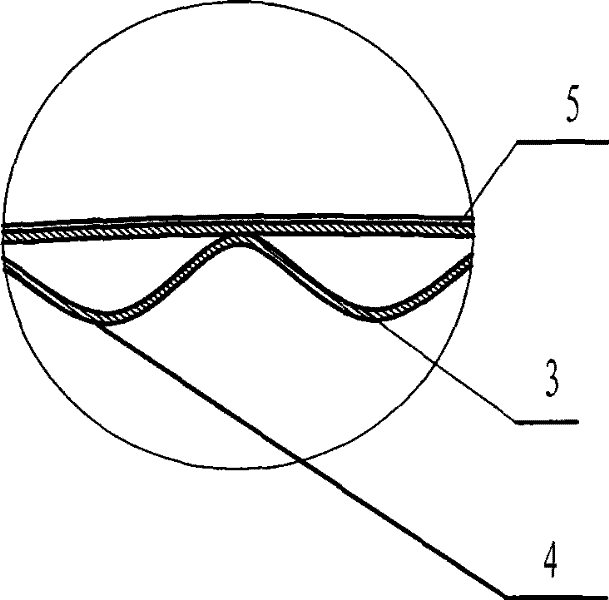

[0022] The new double-wall granary consists of: a roof 1, a body 2 connected to the roof, the body includes an inner wall 3 and an outer wall 5, and the inner wall has an arc-shaped periodic Protrusion 4, the outer wall has intermittent and discontinuous protrusions, the protrusions on the outer wall are distributed along the lateral direction of the bin body, and the protrusions on the inner wall are along the body of the bin Longitudinal distribution, the inner wall and the outer wall are connected to each other to form a thermal insulation closed space.

Embodiment 2

[0023] Embodiment 2: A new double-walled granary, which consists of: a roof 1, a body 2 connected to the roof, the body is equipped with an inner wall 3 and an outer wall 5, and the outer wall has corrugations Shaped periodic protrusions, the inner wall has polygonal periodic protrusions 4, the protrusions on the outer wall are distributed along the lateral direction of the bin body, the protrusions on the inner wall are along the The silo body is distributed longitudinally, and the inner wall and the outer wall are connected to each other to form a thermal insulation closed space, which can be filled with thermal insulation materials to form a thermal insulation granary.

Embodiment 3

[0024] Embodiment 3: A novel double-wall granary, which consists of: a roof 1, a body 2 connected to the roof, the body is equipped with an inner wall 3 and an outer wall 5, and the outer wall has Corrugated periodic protrusions, the inner wall has polygonal periodic protrusions 4, the protrusions on the outer wall are distributed along the lateral direction of the container body, and the protrusions on the inner wall are along the The bin body is longitudinally distributed, and the inner wall and the outer wall 5 are connected to each other to form a thermal insulation closed space.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com