Compressing device for clutch

A compression device and clutch technology, applied in clutches, friction clutches, mechanically driven clutches, etc., can solve the problems of inability to achieve precise torque control and inability to accurately control the movement of clutch discs, and achieve the effect of precise control of torque transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

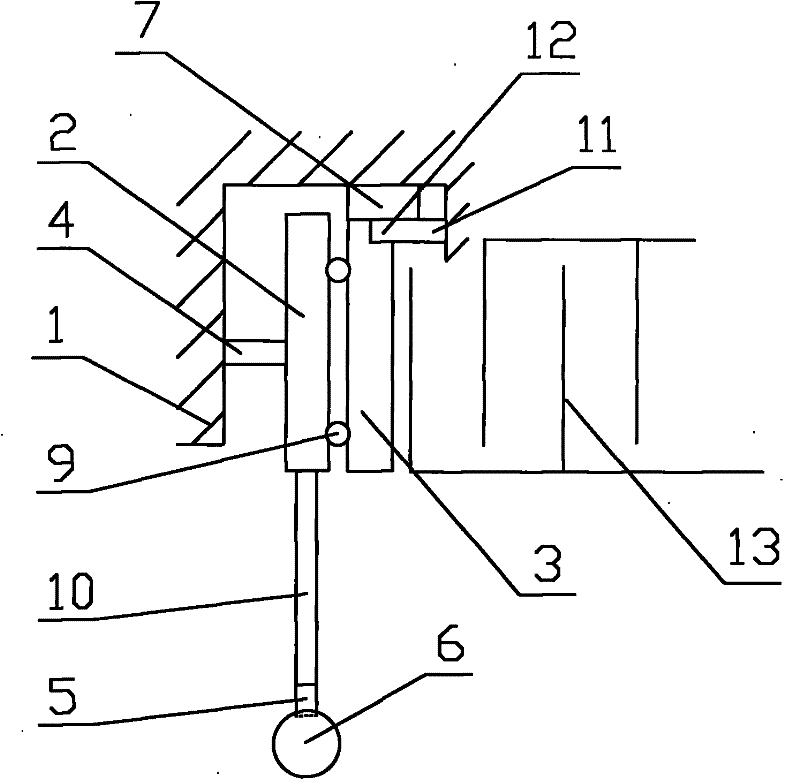

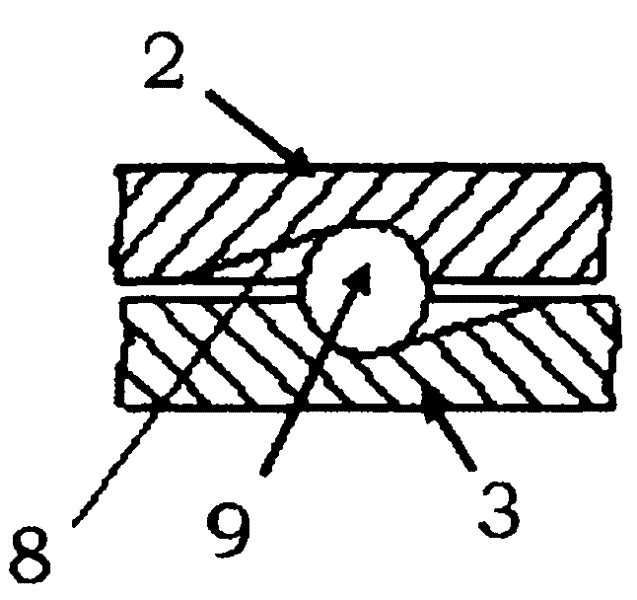

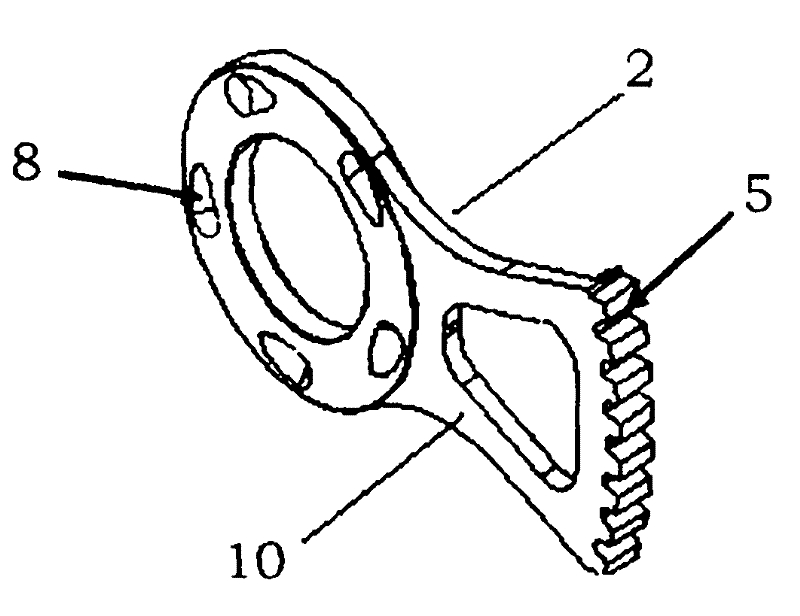

[0017] As shown in the figure, the clutch pressing device of this embodiment includes a housing 1, a main pressure plate 2 and a slave pressure plate 3, the hubs of the main pressure plate 2 and the slave pressure plate 3 are opposite, and the main pressure plate 2 The rotating shaft 4 is fixed to the housing 1, the main pressure plate 1 is axially limited to the rotating shaft 4 and can rotate around the rotating shaft 4; the bottom of the main pressure plate 1 is provided with a transmission rod 10, and the bottom of the transmission rod 10 is provided with a worm gear 5, so The worm gear tooth 5 is matched with a control shaft 6 of a worm structure; the slave pressure plate 3 is arranged on the side of the main pressure plate 2, and is installed on the housing 1 through a spline 7; the main pressure plate 2 and the slave pressure plate The opposite sides of the disc 3 are all provided with track grooves 8, and the track grooves 8 are located on the circumference with the cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com