Methods of making metal oxide nanoparticles

A technology of nanoparticles and oxides, applied in ferrous oxides, iron compounds, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0089] These examples are for illustrative purposes only and are not intended to limit the scope of the appended claims. All parts, percentages, ratios, etc. in the examples are by weight unless otherwise specified.

[0090] Ethanol (95%), hexane, acetone, isopropanol and toluene were obtained from EMD (San Diego, CA). All other reagents were obtained from Sigma-Aldrich Chemical Company (Milwaukee, WI) unless otherwise noted.

[0091] Test Methods

[0092] Transmission Electron Microscopy (TEM)

[0093] Samples for TEM imaging were prepared by placing a drop of undiluted sample or by placing a drop of diluted sample (1 part sample mixed with 2 parts hexane) on a 400-mesh copper TEM grid on an irregular carbon ( Ted Pella Company, Redding, CA) with an ultrathin carbon substrate on top of the grid. A portion of the sample drop was removed by touching the sides or bottom of the grid with filter paper. Allow remaining sample to dry. This allows the particles to remain on...

example 1

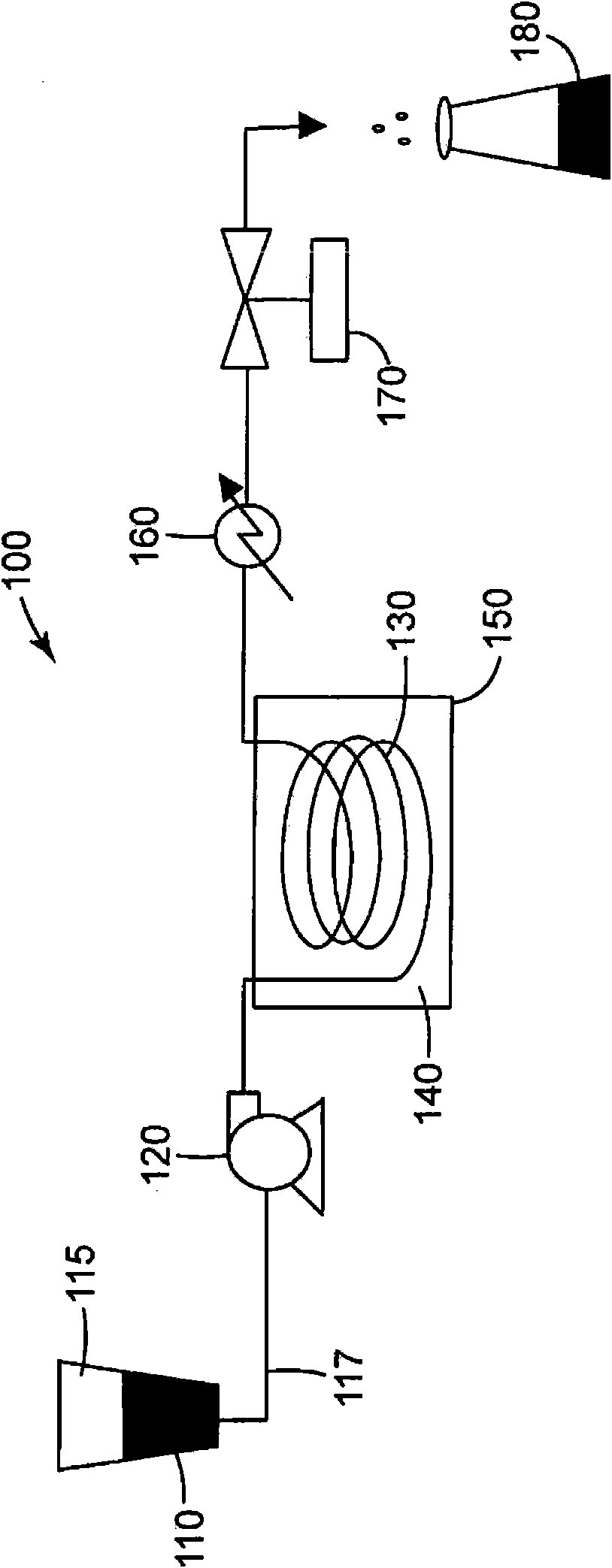

[0128] The feed composition was prepared by adding ferric oleate precursor (161.2 grams), prepared as described in Preliminary Example 1, to a plastic container. Octadecene (750 mL) was added followed by oleic acid (25.3 g).

[0129] The feed composition was pumped through the tubular reactor as described in Table 1 at a rate of 2 ml / min. The tubular reactor was immersed in a DURATHERM S oil bath heated at 300°C. The residence time (ie, the time the reacting stream is within the portion of the tube submerged in oil) was 38 minutes. Reactor conditions are summarized in Table 2. The product was a black solution.

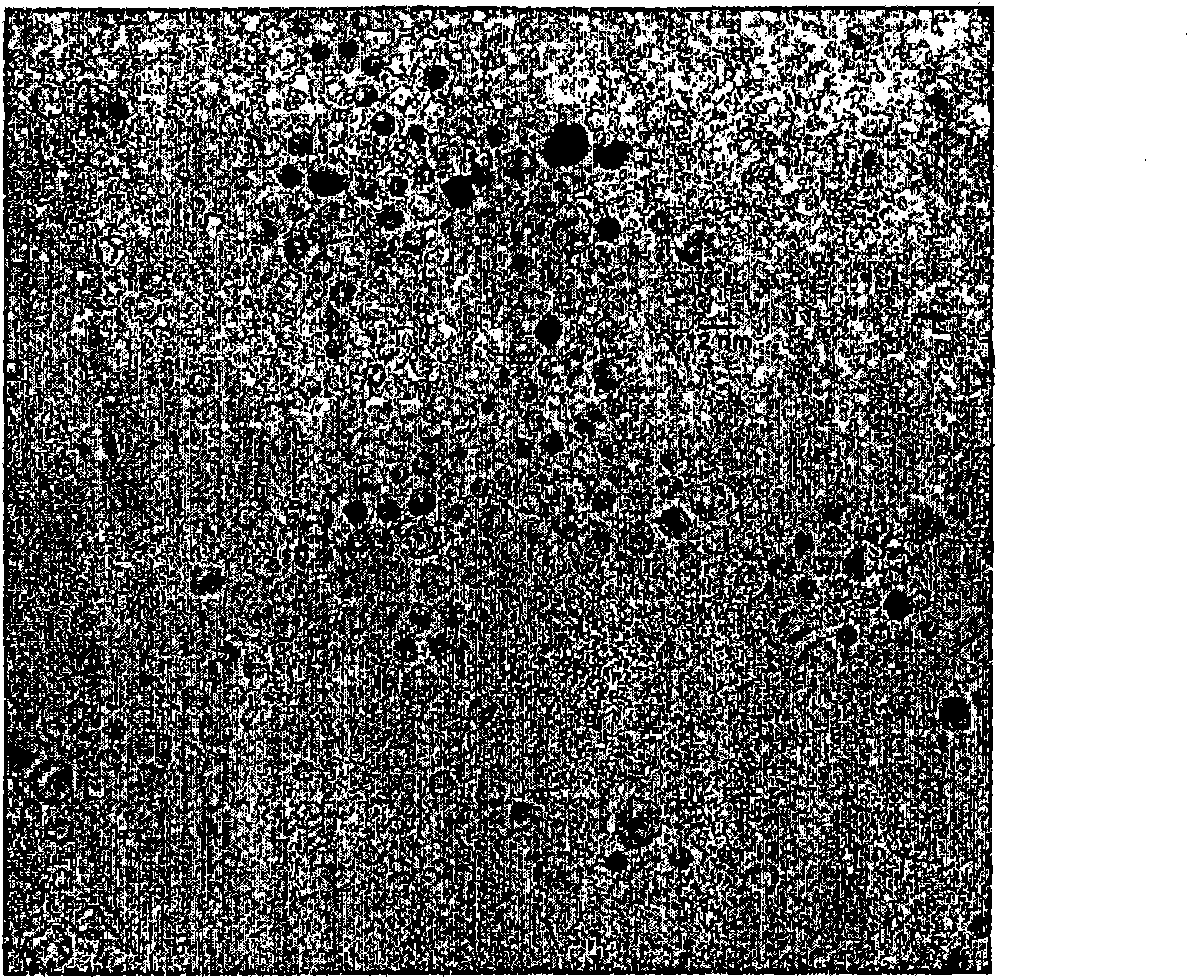

[0130] Particles in the reactor product were washed according to Separation Method 1. Two drops of the resulting dispersion were diluted in 2 ml of hexane. The sample was evaluated using TEM and XRD. Representative TEM images are shown in image 3 middle. The magnification is 300,000X. The characterization results are summarized in Table 3.

example 2

[0132] The feed composition was prepared by adding iron oleate precursor (92.4 grams), which was prepared as described in Preliminary Example 1, to a plastic container. Octadecene (412 g) was added followed by oleic acid (14.2 g).

[0133] The feed composition was pumped through the tubular reactor as described in Table 1 at a rate of 2 ml / min. The tubular reactor was immersed in a DURATHERM S oil bath heated at 300°C. The residence time was 38 minutes. Reactor conditions are summarized in Table 2. The product was a black solution.

[0134] The drops of reactor effluent were diluted in hexane at a concentration of 1-10 drops / ml. The samples were evaluated using TEM. The characterization results are summarized in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap