Shape evaluation method, shape evaluation device, and 3d inspection device

An evaluation method and evaluation device technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of difficult inspection results, inspection results that cannot be strictly reproduced, and image reproducibility that cannot be fully obtained, and achieve continuous inspection process, The effect of the simple inspection process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

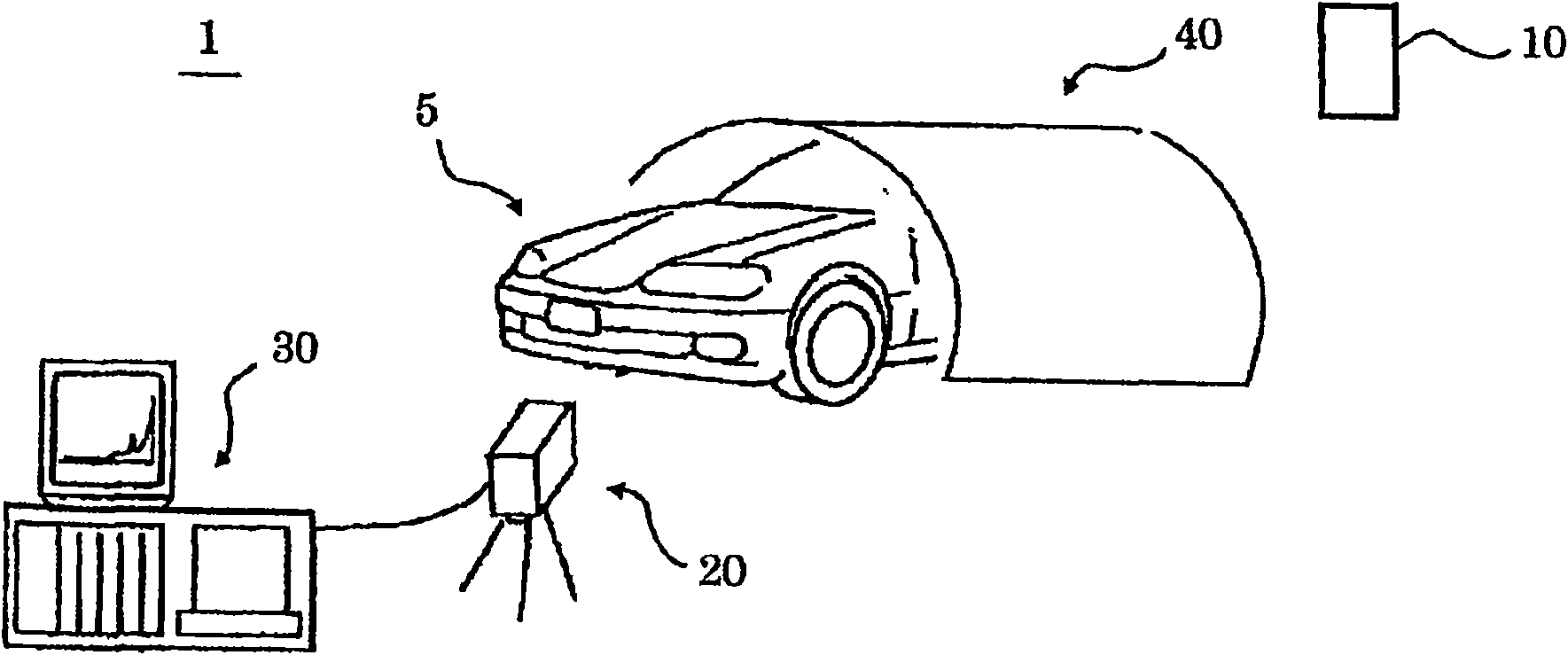

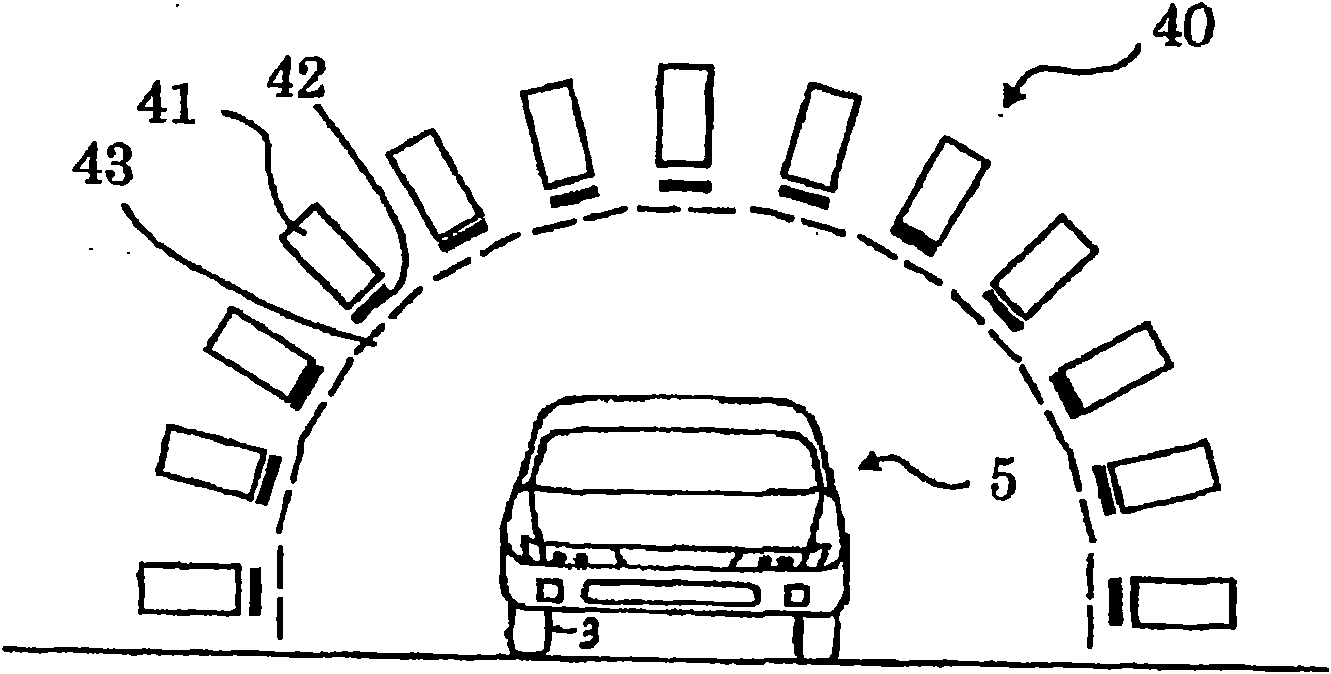

Below, refer to Figures 1 to 15 The shape evaluation apparatus and shape evaluation method according to Example 1 of the present invention will be described. In this embodiment, an example of evaluation of the surface shape of an automobile body as an evaluation object will be described.

[0026]

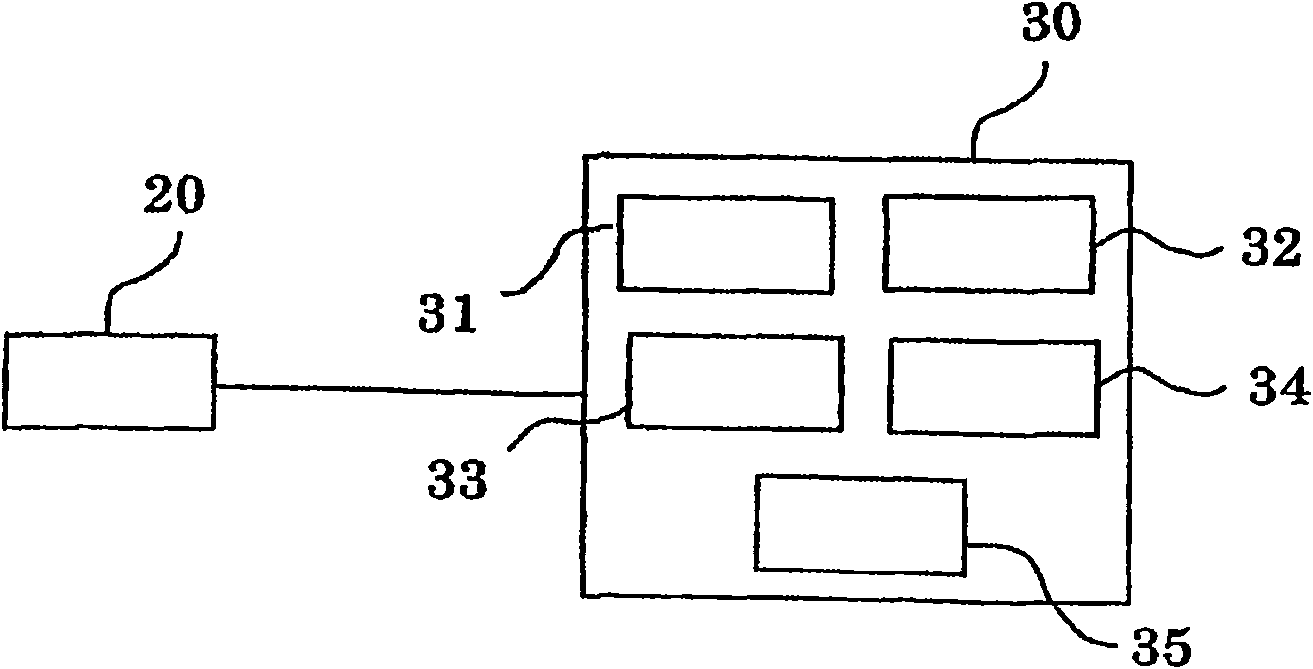

figure 1 A shape evaluation device 1 for evaluating the surface shape of an automobile body (hereinafter referred to as "workpiece") as an evaluation object is schematically shown. The shape evaluation device 1 includes a measurement unit 10 that optically measures the external shape of the workpiece 5 , and an arithmetic processing unit 30 that acquires measurement data measured by the measurement unit 10 and analyzes the input measurement data. Hereinafter, each structure will be described in detail.

[0027]

The measuring unit 10 is a known device for three-dimensional shape measurement. Specifically, this device optically measures the external shape of the workpiece 5 and s...

Embodiment 2

In this embodiment, since the object to be evaluated is created imaginary, there is no need for a measuring unit to specifically measure its shape. In the present embodiment, the surface shape of the object to be evaluated is evaluated on a virtual basis. Therefore, as Figure 16 As shown, in the shape evaluation device 1', the simulation device 50 that virtualizes the object to be evaluated is connected to the arithmetic processing unit 30 described in the above-mentioned embodiment. In addition, in this embodiment, an example in which the arithmetic processing unit 30 and the simulation device 50 are configured separately is given, but they may also be configured by an integrated computer. Hereinafter, an example in which such a shape evaluation device 1' evaluates the surface shape of a panel that is virtually constructed on the simulation device 50 is hypothetical, using Figure 17 The flow chart shown is described.

[0055]

First, the shape data of a panel constructed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com