Method for constructing bottom of ladle

A manufacturing method and technology of molten steel tanks, which are applied in the direction of manufacturing tools, casting molten material containers, metal processing equipment, etc., can solve the problems of increasing costs and delaying production, and achieve the effect of reducing labor intensity and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

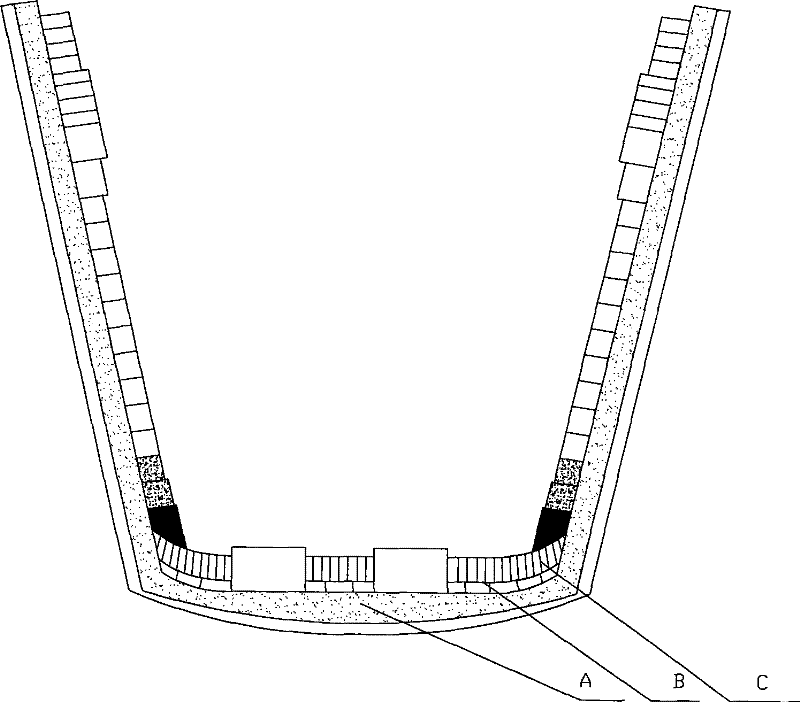

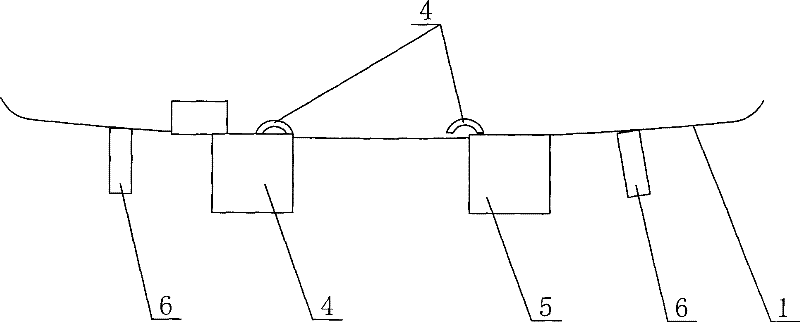

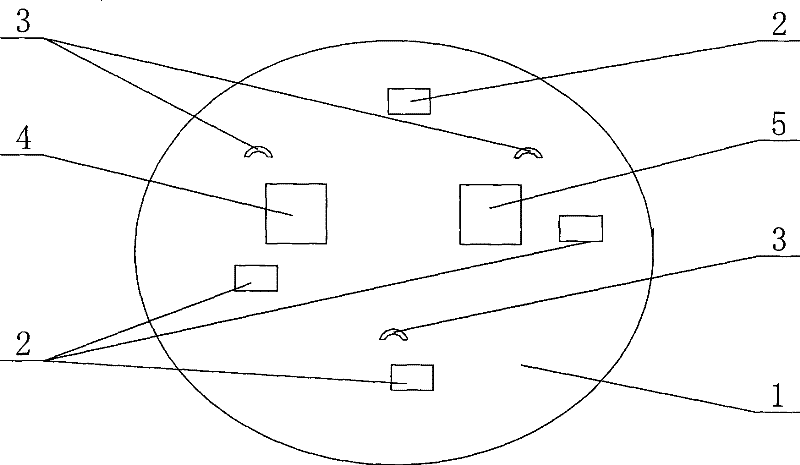

[0019] See figure 1 , a method for manufacturing the bottom of a steel ladle, the method comprising the steps of:

[0020] (1) Make the permanent bottom A of the molten steel tank into a concave permanent bottom, and use a concave mold to make it; put the concave mold into the bottom of the tank smoothly, so that the distance between the edge of the mold and the wall of the molten steel tank is balanced, and protect the air-permeable square brick Sleeve, nozzle brick protection sleeve is aligned with ventilating brick mouth and nozzle brick mouth;

[0021] (2) The stirred permanent bottom castable is poured into the bottom of the tank from the gap between the mold and the tank wall until the upper surface of the castable touches the lower surface of the mold. till pulp;

[0022] (3) Hang out the mold after the castable is solidified;

[0023] (4) Carry out health maintenance for the permanent bottom, and the health maintenance should not be less than 24 hours;

[0024] (5)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com