Improved carpenter clamp

A woodworking clip and positioning plate technology, applied in the field of machinery, can solve the problems of inconvenient use, inconvenient conversion of pressing and support, low working speed of woodworking clips, etc., and achieves the effect of convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

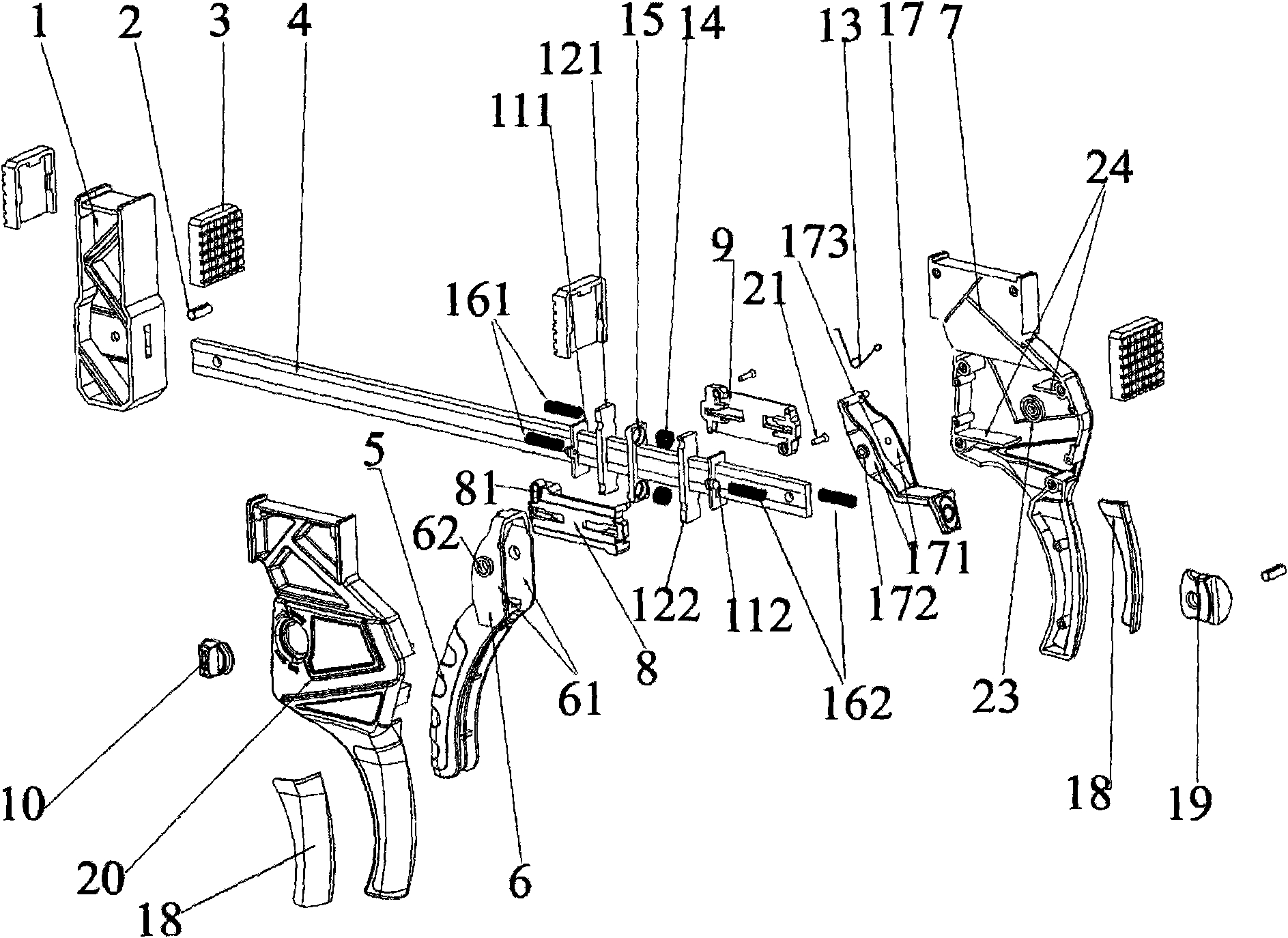

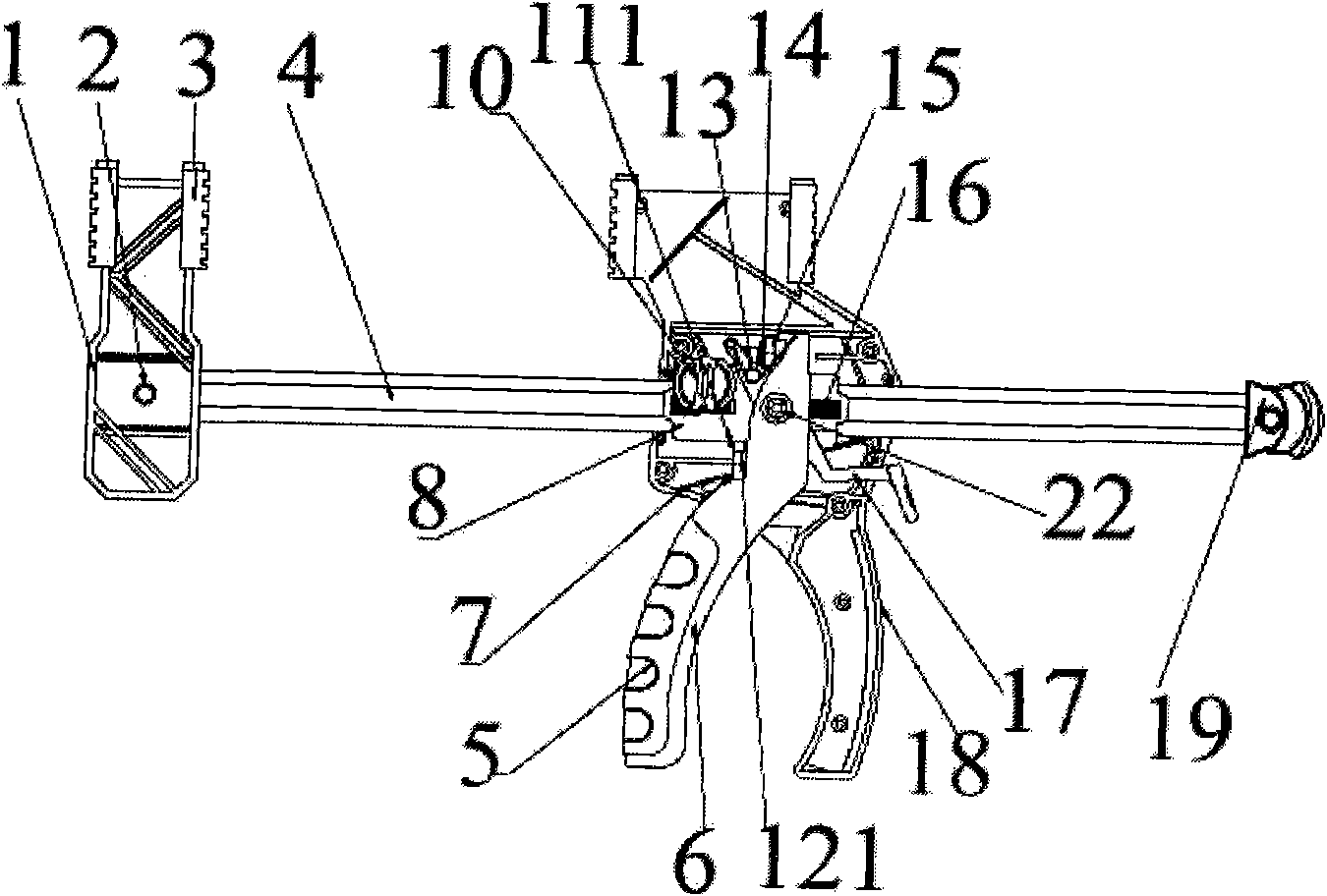

[0015] Such as figure 1 and figure 2 As shown, an improved woodworking clamp of the present invention is composed of a straight slide bar 4, a fixed pincer arm 1, a movable pincer arm 7 and a driving device, and the fixed pincer arm 1 is fixedly arranged on the straight slide bar 4, the movable pincer arm 7 is fixedly arranged on the top of the driving device, and the driving device is sleeved on the straight sliding rod 4, wherein the section of the straight sliding rod 4 is rectangular, and the driving device is composed of a shell body 20, driving block 8 and driving handle 6, the lower part of the outer casing 20 is fixedly provided with a fixed handle 18, the driving block 8 is arranged in the outer casing 20, and both ends of the outer casing 20 are provided with The housing through hole, the straight slide rod 4 passes through the housing through hole, the driving handle 6 is composed of a lever 61, and the fulcrum of the lever 61 is provided with a shaft 62, so The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com