Fixing construct of fixed part as well as clip

A technology for fixing components and components, applied in the direction of superstructure, vehicle components, threaded fasteners, etc., can solve the problems that the gap cannot be obtained, and the insertion shaft length of pin components cannot be increased.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

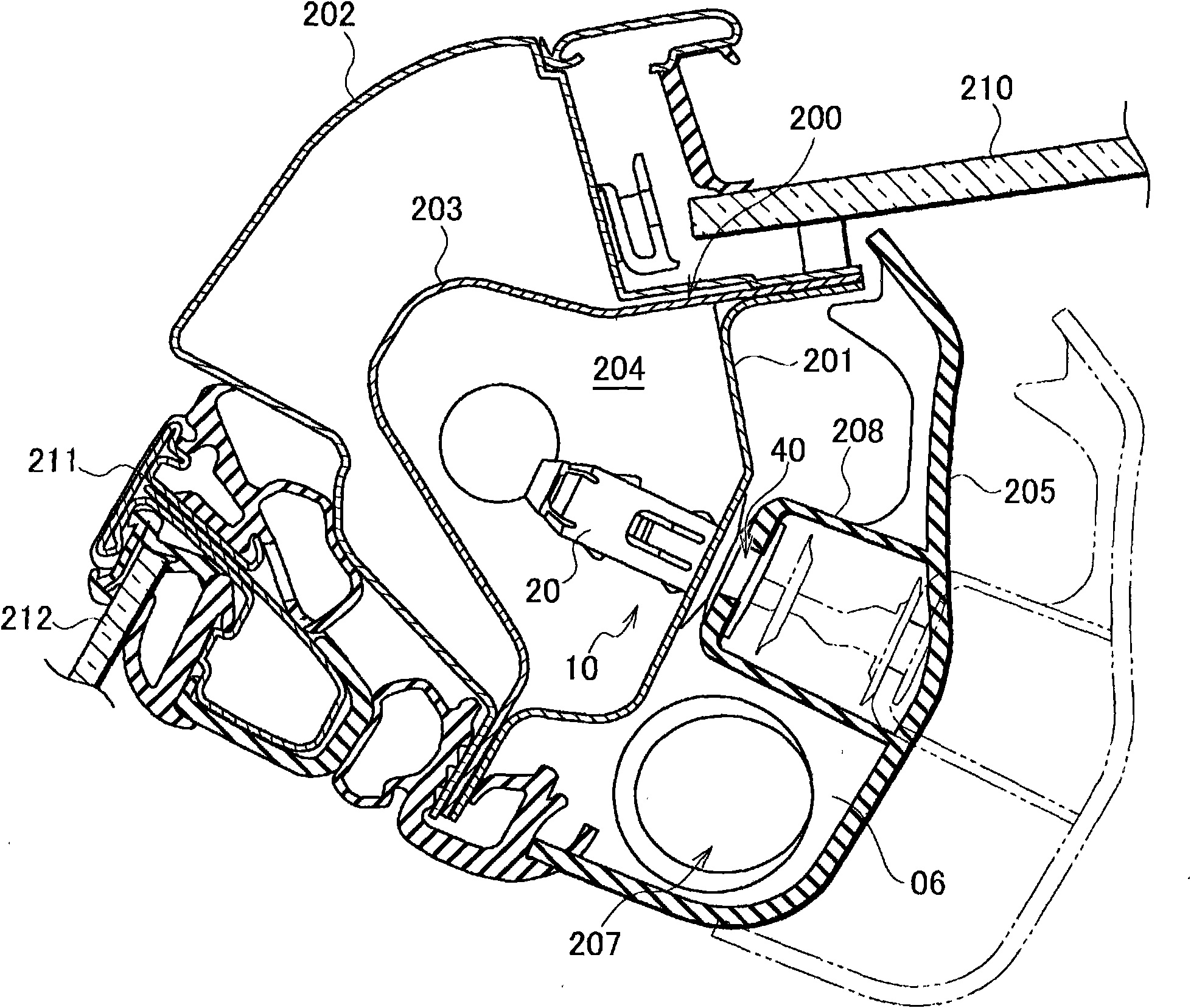

[0060] First refer to figure 1 The following describes an embodiment in which the fixed member fixing structure of the present invention is applied to a fixing structure for mounting a decoration on a front pillar of an automobile. figure 1 It is a horizontal cross-sectional view of the front pillar of the car.

[0061] The front pillar (fixing member) 200 is formed of a box-shaped cross-sectional shape of an inner member 201 and an outer member 202 that are combined with each other. A bracket 203 is also provided inside the front pillar 200 to narrow the internal space 204 of the front pillar 200.

[0062] A decoration (fixed member) 205 is attached to an interior component 201 located inside the vehicle compartment by a clip 10. A side airbag 207 is provided inside the decoration 205, that is, in the decoration inside space 106 defined between the decoration 205 and the inner member 201.

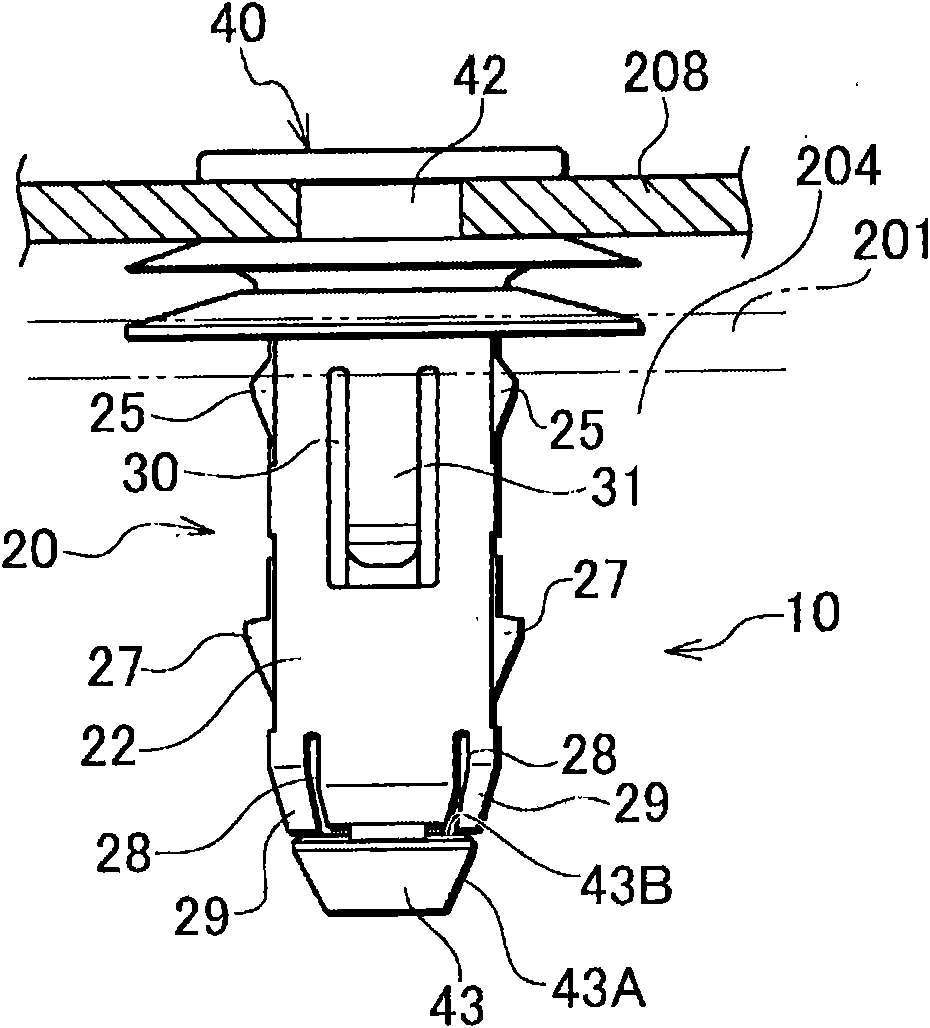

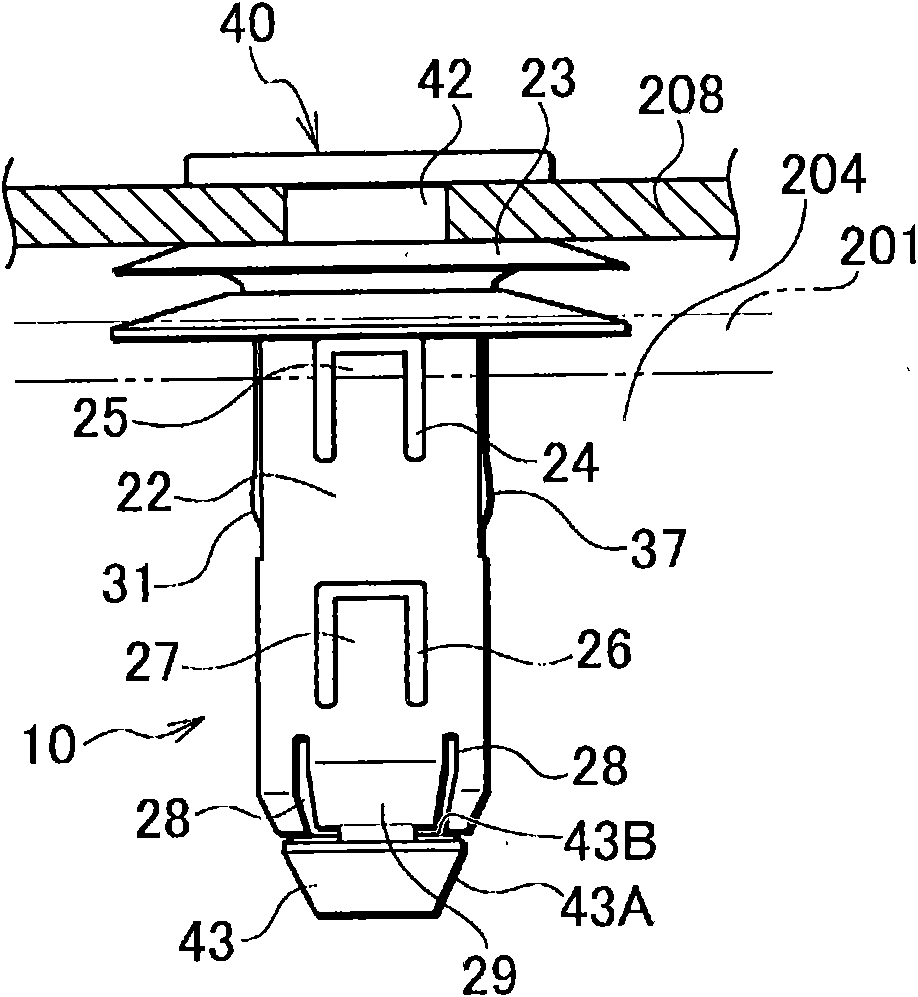

[0063] The clip 10 is a ring pin type clip composed of a ring member 20 and a pin member 40....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com