Installation structure of cloth guide roller in dyeing device

The technology of printing and dyeing equipment and installation structure is applied in the field of installation structure of cloth guide rollers, which can solve the problems of increasing production cost, deviation and wrinkling of cloth guide rollers, expensive cloth guide rollers, etc., so as to prolong the service life and reduce production. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solution of the present invention, its working principle and advantages will be further described below in conjunction with the accompanying drawings and specific embodiments.

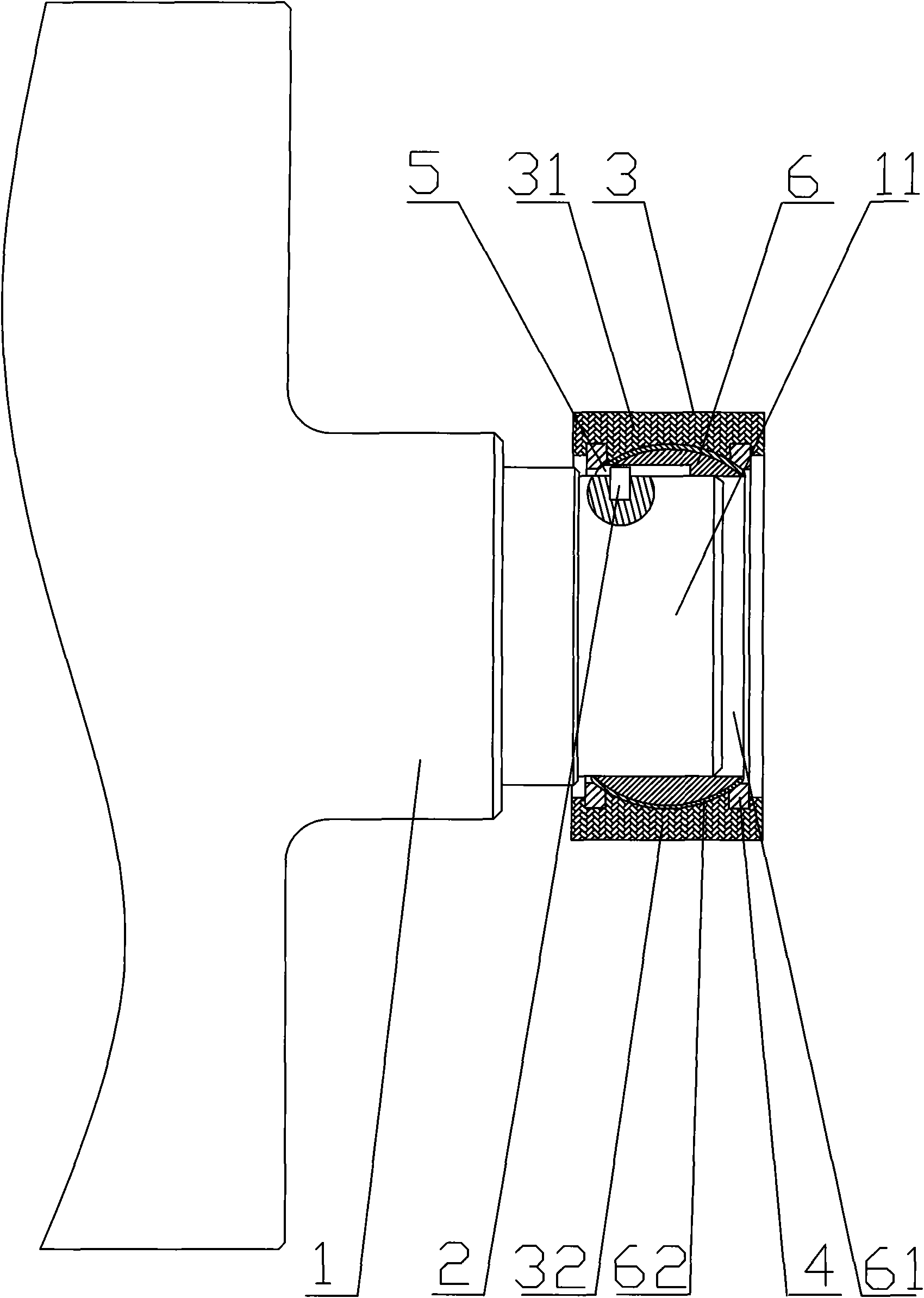

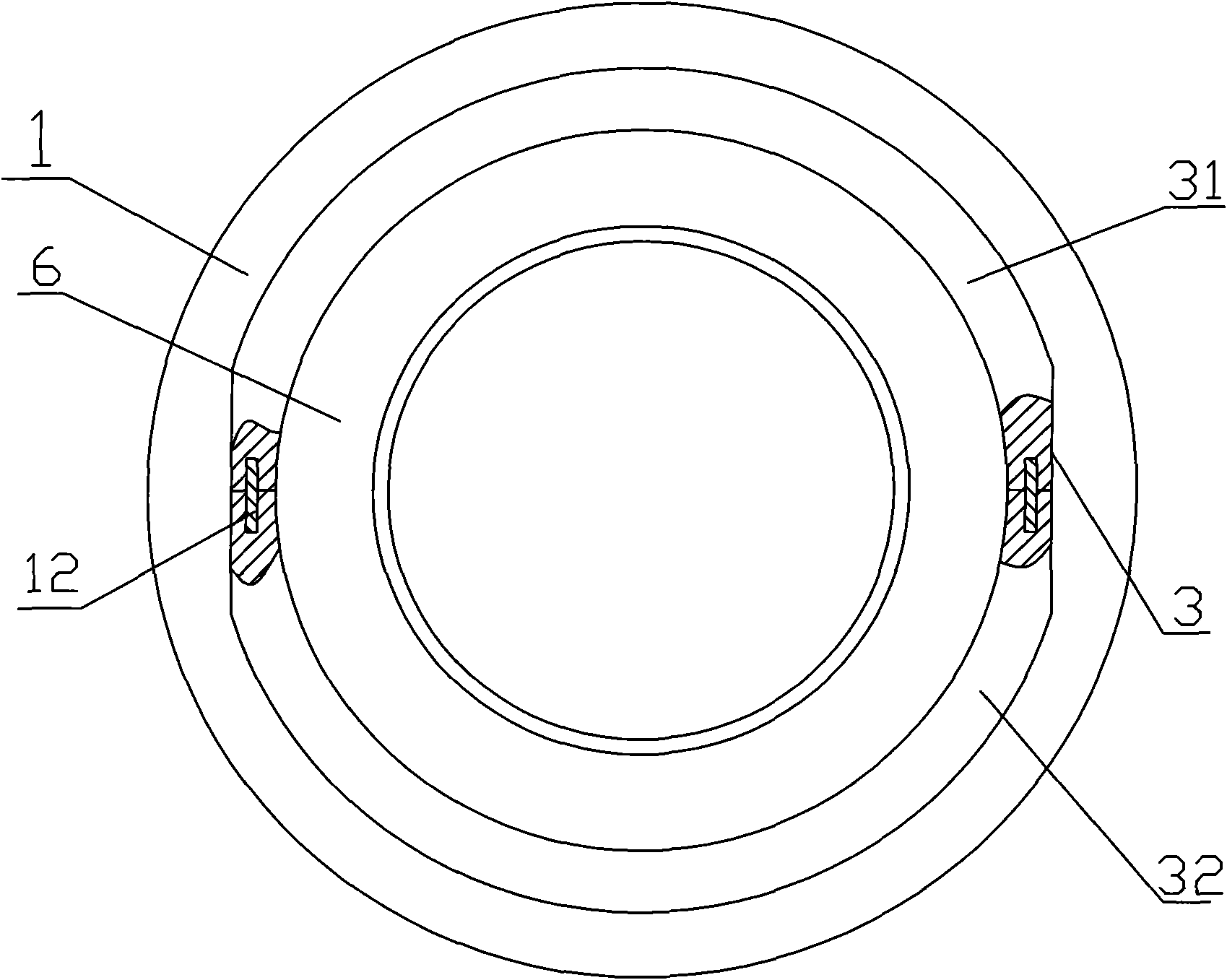

[0015] figure 1 , figure 2 As shown, the installation structure of the cloth guide roller in a kind of printing and dyeing equipment, the shaft head 11 of the cloth guide roller 1 is arranged in the shaft hole 61 of the ball sleeve 6 made of stainless steel and connected with the ball sleeve 6, the ball sleeve 6 The outer surface of the ball is spherical, and the outer surface of the ball sleeve 6 is provided with a wear-resistant layer 62, which prolongs the service life of the ball sleeve 6. A shaft sleeve 3 is arranged on the outside of the ball sleeve 6, and the shaft sleeve 3 is made of ultra-high polymer material or graphite. In this embodiment, the shaft sleeve 3 is composed of two half shaft sleeves 31, 32 closed by the pin shaft 12 , In actual production, tie hoops can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com