Self-sealing self-aligning roller bearing

A self-sealing self-sealing technology for self-aligning roller bearings, applied to rolling contact bearings, shafts and bearings, bearing components, etc., can solve problems such as poor sealing effect, inability to play a sealing role, and changing the installation size of bearings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in conjunction with accompanying drawing.

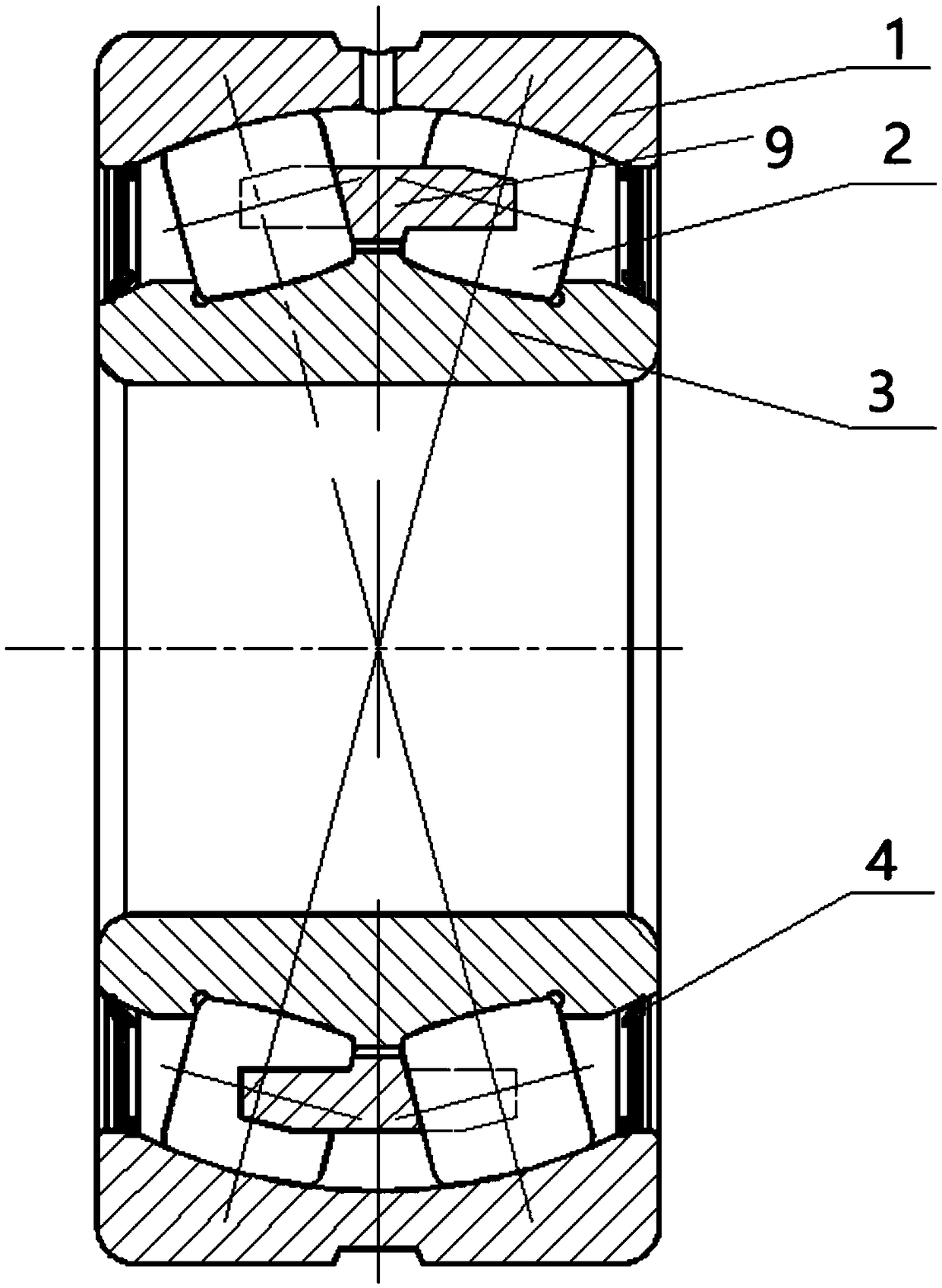

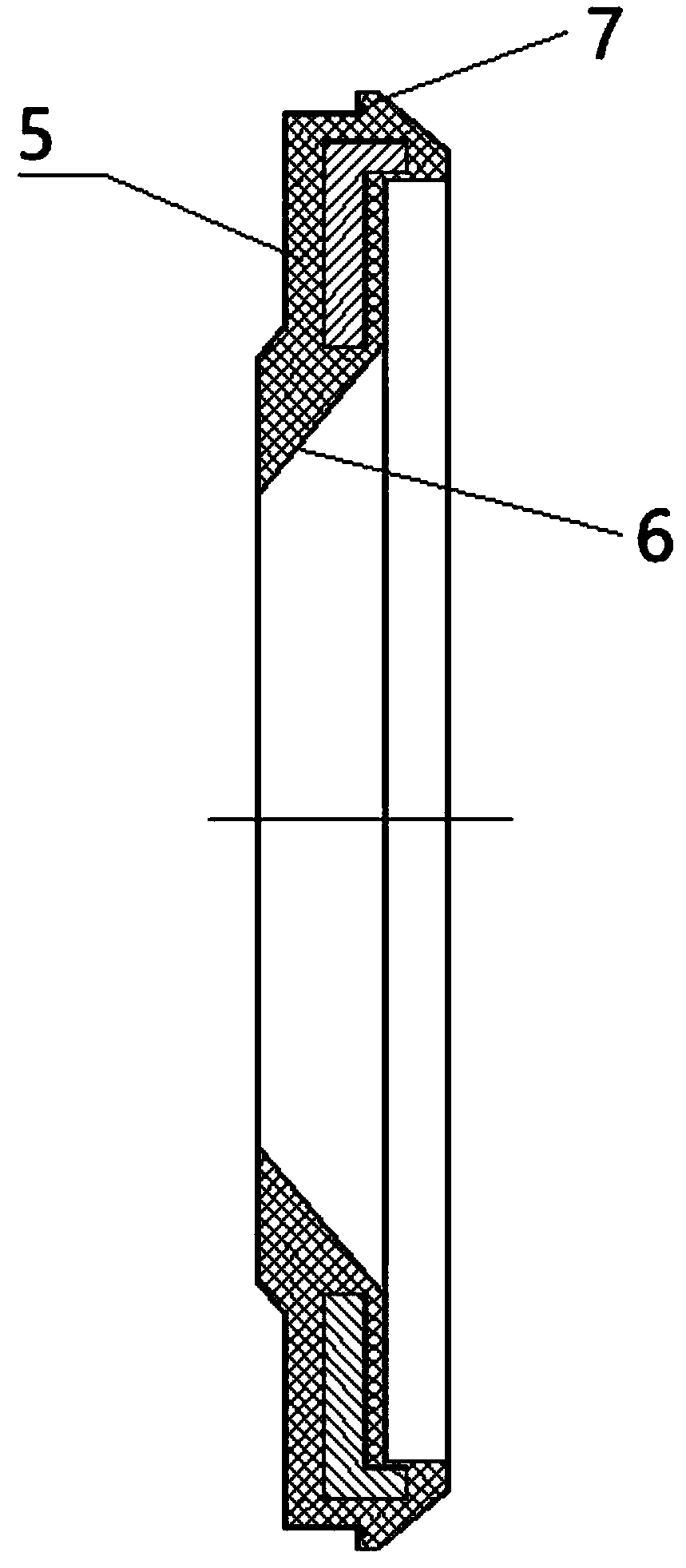

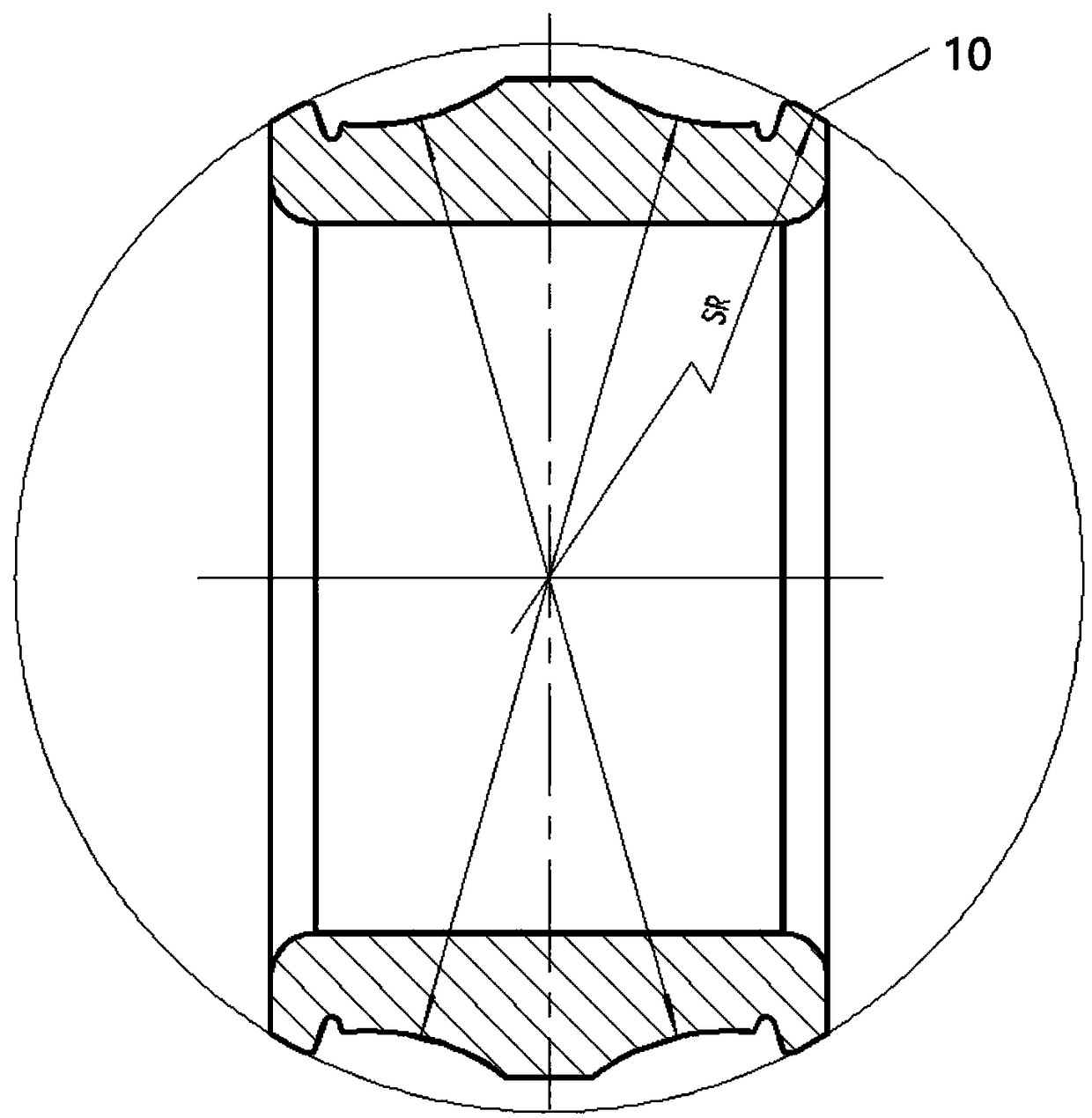

[0019] A self-sealing spherical roller bearing is composed of an outer ring 1, an inner ring 3, a roller 2, a cage 9 and a sealing ring 4. The upper part of the inner ring 3 is provided with a cage 9, and the roller 2 is installed on the cage 9. The upper part of the roller 2 is the outer ring 1. The outer diameter of the small rib 10 of the inner ring is arc-shaped, and the two small ribs The outer diameter of the side forms a sphere with the center of rotation of the bearing as the center; the sealing ring 4 is a circular ring, and its structure is an annular skeleton 5, the outer diameter of the annular skeleton has a protrusion 7 structure, and the inner diameter is a sealing lip of an inclined plane 6. The sealing ring 4 is installed between the outer ring 1 and the inner ring 3 of the bearing.

[0020] The sealing ring 4 is made of nitrile rubber.

[0021] The protrusion 7 on the oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com