Fixing fixture of throwing machine table and window-type press board thereof

A pressing plate and window type technology, which is applied in the field of fixing fixtures and window type pressing plates, can solve problems such as warping of the carrier plate 21, packaging failure, and indentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

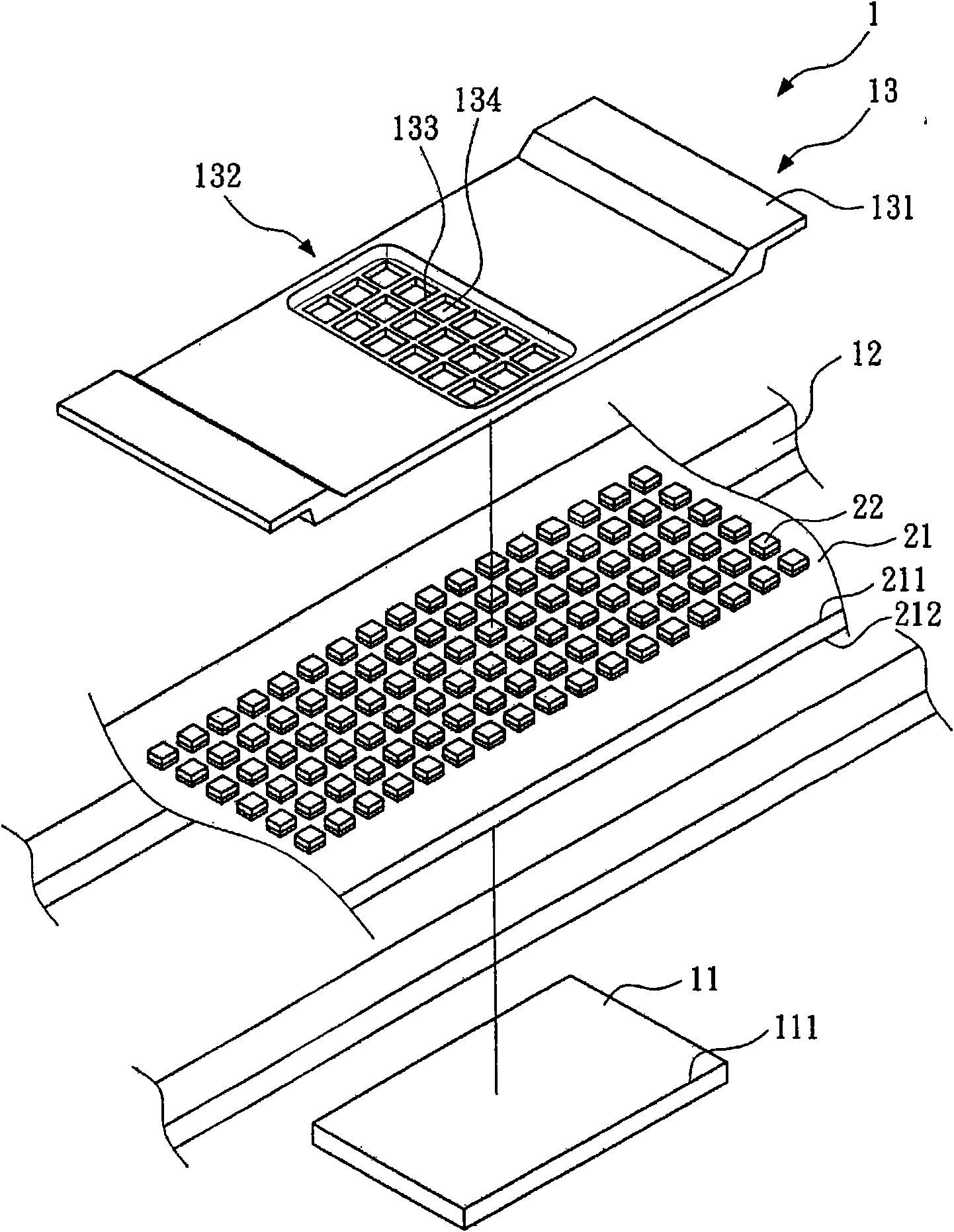

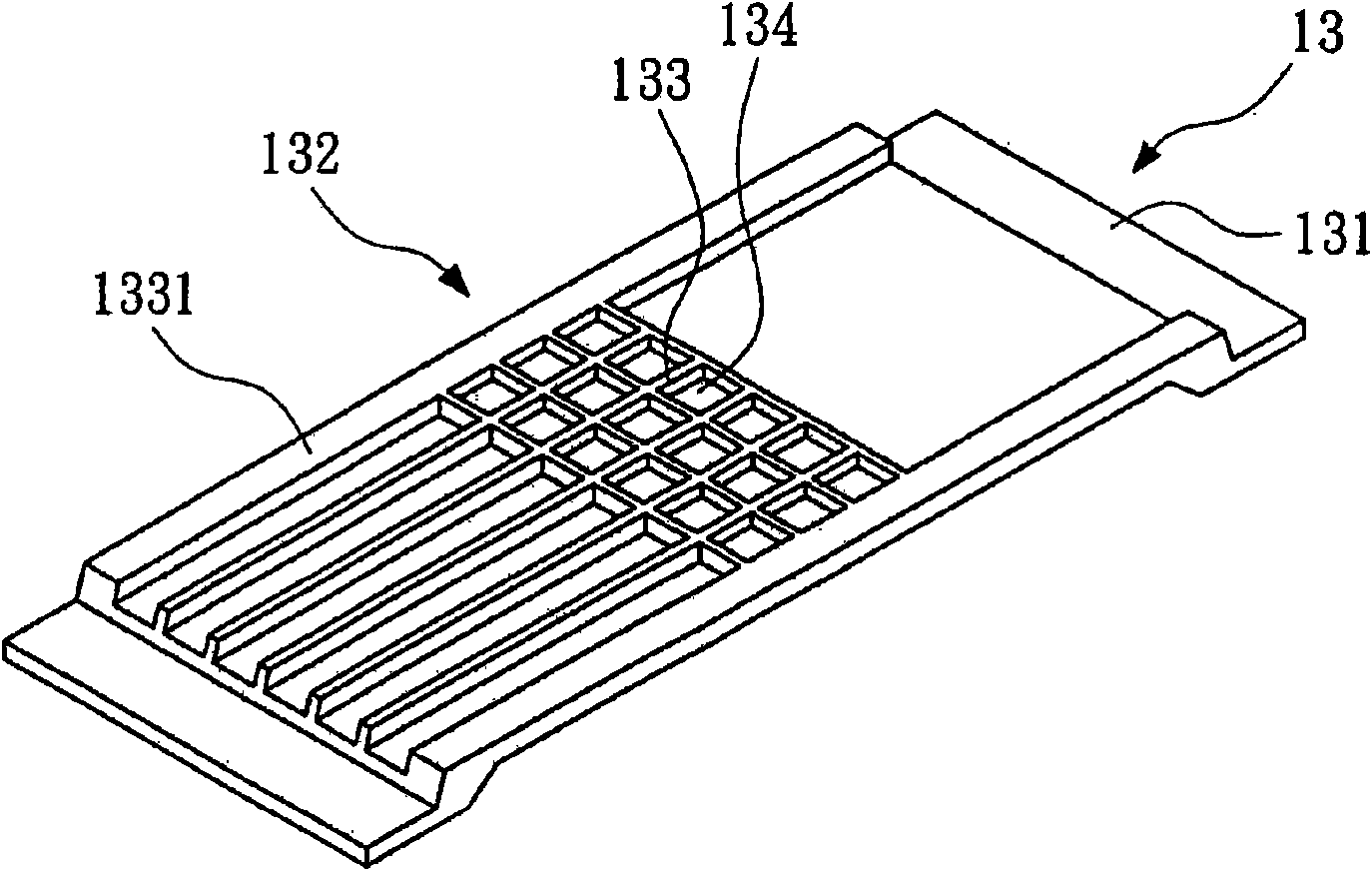

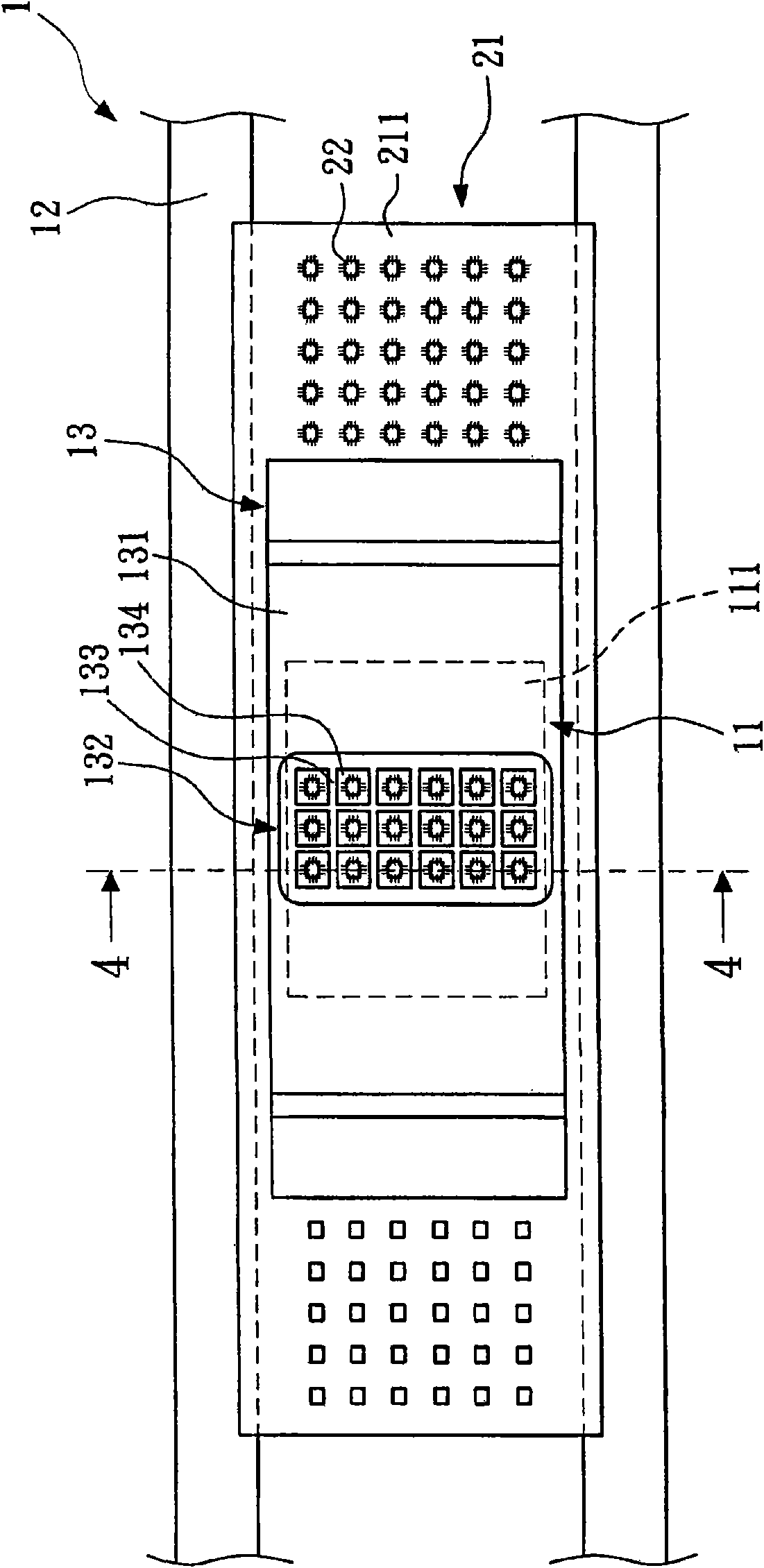

[0088] refer to Figure 6 , shows an exploded schematic view of the first embodiment of the fixing jig 3A of the wire bonding machine of the present invention. The fixing jig 3A is used to fix a carrier board 23 to facilitate the wire bonding process. The carrier board 23 includes an upper surface 231 and a lower surface 232 , and a plurality of chips 24 are adhered to the carrier board 23 . In this embodiment, the carrier board 23 can be a substrate strip or a lead frame, and the chips 24 are adhered to the upper surface 231 of the carrier board 23 . The fixing fixture 3A includes a hot plate 4 and a window-shaped pressing plate 5 . In this embodiment, the fixing fixture 3A further includes two rails 6 located on two sides of the heating plate 4 to support two sides of the carrying plate 23 . The heating plate 4 includes an adsorption surface 41 for supporting the lower surface 232 of the carrying plate 23 and providing heat energy to the carrying plate 23 . In other applic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com