Substrate heating apparatus

A technology for heating devices and substrates, which is applied in the fields of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., and can solve problems such as solar cell efficiency degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

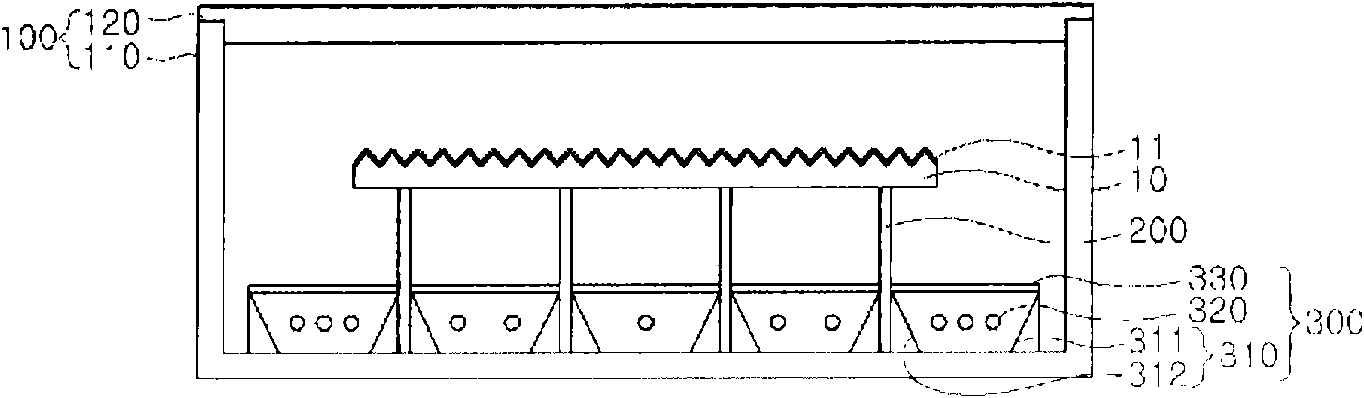

[0025] figure 2 is a cross-sectional view of a substrate heating apparatus according to an embodiment of the present invention.

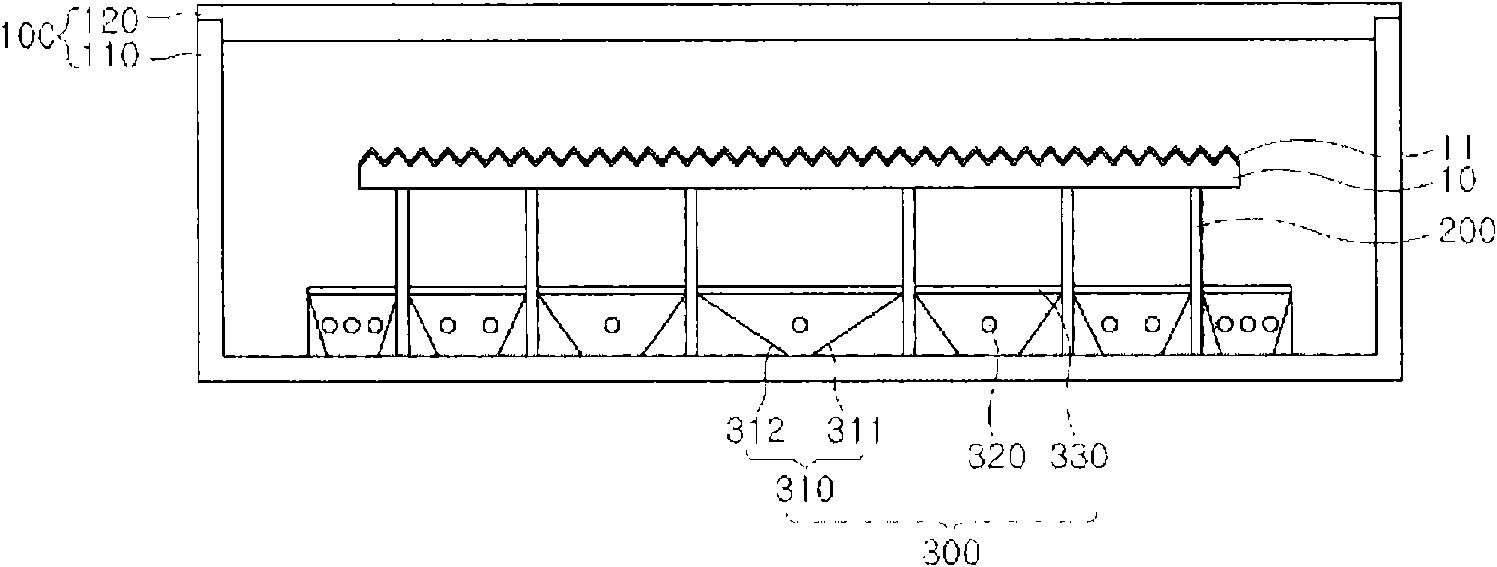

[0026] Figures 3 to 5 is a modified cross-sectional view of the substrate heating apparatus according to the embodiment of the present invention.

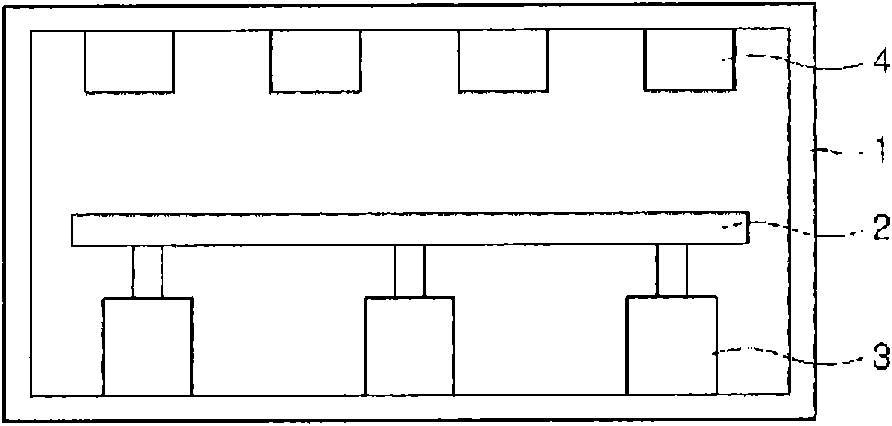

[0027] refer to figure 2 , The substrate heating apparatus according to the embodiment of the present invention includes: a chamber 100 ; a substrate supporting unit 200 supporting the substrate 10 ; and a heating unit 300 disposed under the substrate 10 . The heating unit 300 includes: a plurality of reflecting units 310 ; a plurality of lamp heating units 320 , each of which is disposed inside the plurality of reflecting units 310 ; and a short-wavelength blocking layer 330 disposed above the lamp heating units 320 .

[0028] The chamber 100 includes a hollow chamber body 110 and a chamber cover 120 covering the chamber body 110 . The chamber body 110 is formed in a cylindrical shape with an ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com