Fuel cell

A fuel cell and fuel technology, which is applied to fuel cells, fuel cell components, solid electrolyte fuel cells, etc., can solve problems such as position offset, the inability of sealing parts to be accurately embedded in the flow path, and the reduction of power generation efficiency of fuel cell systems. , to achieve the effect of suppressing mixing, not easy to position offset, and easy to locate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

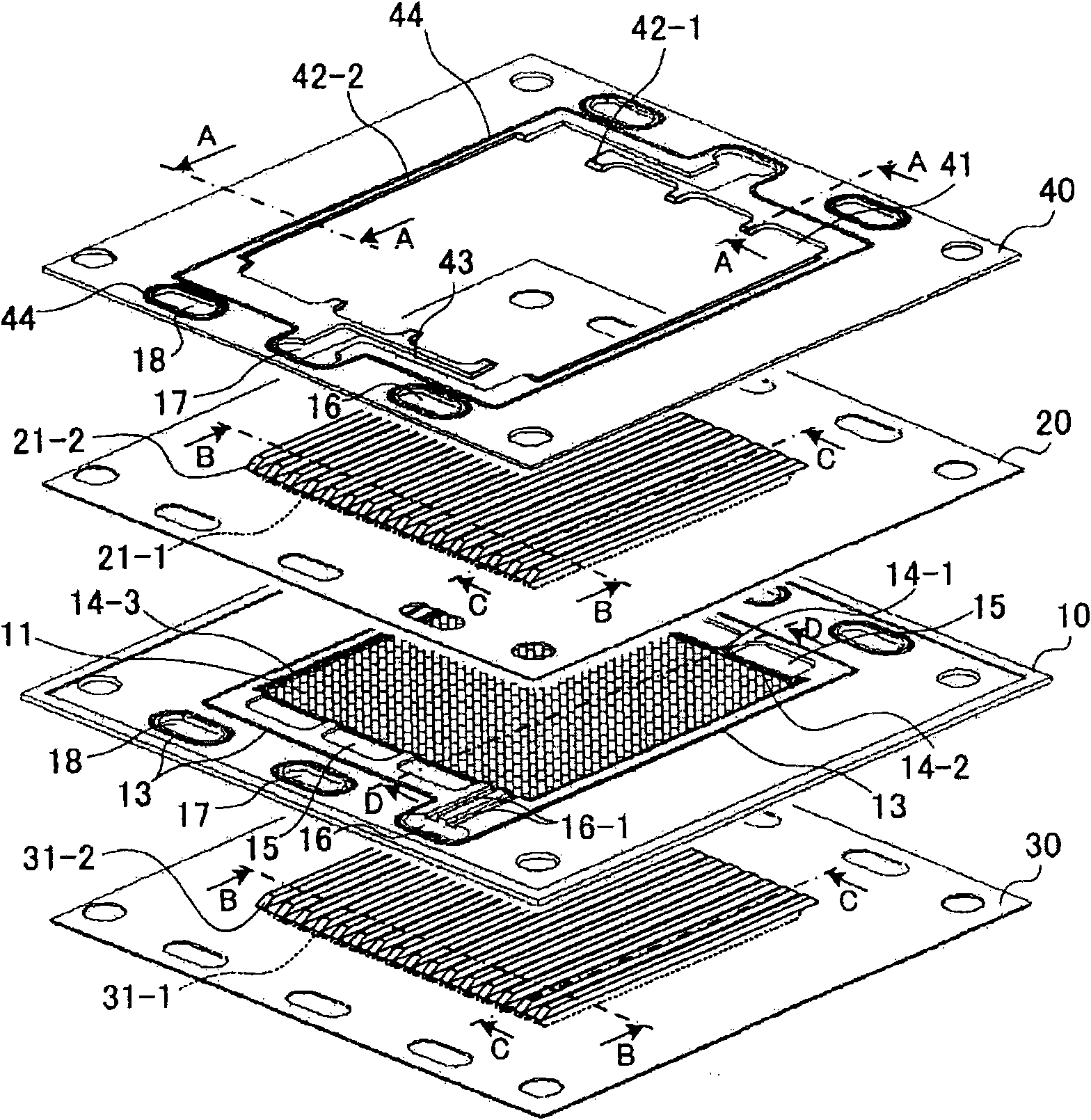

[0114] Figure 1A It shows the situation before lamination of the single fuel cell, in which 1) a linear flow path is formed in the center of each separator, and a turn-back portion of the flow path is formed on the frame holding the MEA, and 2) ) is provided with a spacer frame that allows cooling water to flow through the separator flow paths arranged between the fuel cells.

[0115] Figure 1A A plan view of each component of a frame holding an MEA (MEA holding frame) 10 , an anode separator 20 , a cathode separator 30 , and a separator frame 40 is shown.

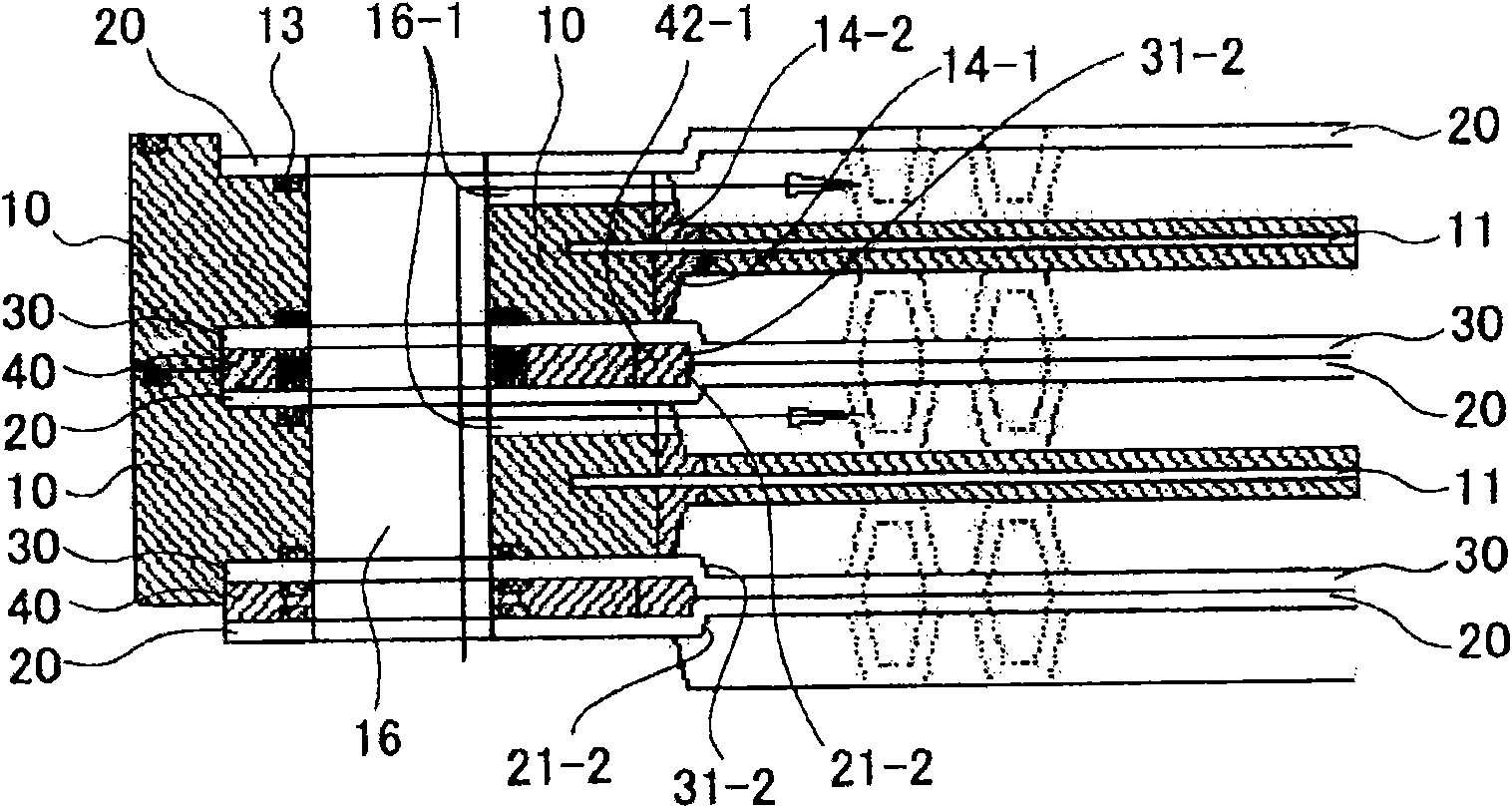

[0116] Figure 5A is the section at A of the isolation frame 40, Figure 5B is the section at B of separators 20 and 30, Figure 5C represents the cross-section at C of the separators 20 and 30, Figure 5D A cross section at D of the MEA holding frame 10 is shown.

[0117] The MEA holding frame 10 can be fabricated by forming a polypropylene frame (220 mm long x 220 mm wide) around the MEA 11 (for example, 150 mm l...

Embodiment approach 2

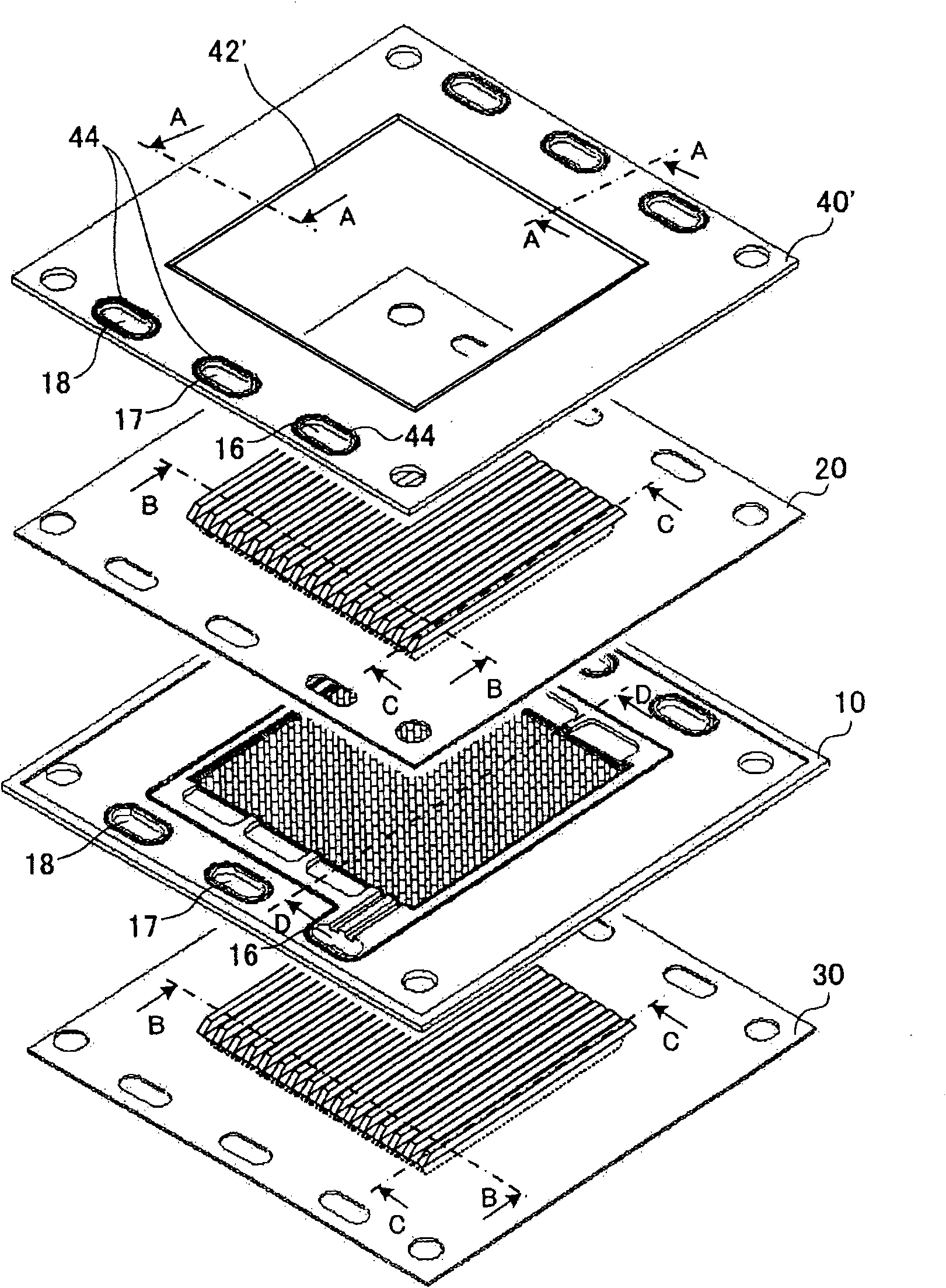

[0134] figure 2 The state before lamination of the single fuel cell is shown, and the single fuel cell has 1) a linear flow path formed in each separator, and a turn-back portion of the flow path formed in the frame holding the MEA, and 2) a The spacer frame is arranged between the fuel cells and does not allow cooling water to flow between the fuel cells.

[0135] figure 2 It is a top view of the MEA holding frame 10, the anode separator 20, the cathode separator 30, and the isolation frame 40'. The MEA holds the frame body 10, the anode separator 20, the cathode separator 30 and the single fuel cell of Embodiment 1 ( Figure 1A )same.

[0136] On the other hand, the difference is that, Figure 1A The illustrated single fuel cell has a spacer frame 40, whereas, figure 2 The illustrated fuel cell has a spacer frame 40'. That is, in the second embodiment, the cooling water of the fuel cell does not flow through the flow path between the stacked fuel cells. That is, co...

Embodiment approach 3

[0139] image 3 The state before lamination of single fuel cells is shown. The single fuel cells are 1) formed with linear flow paths in each separator and folded parts of the flow paths formed in the frame holding the MEA, and 2) arranged with a spacer frame arranged between the fuel cells and for allowing cooling water to flow through the separator flow path, and 3) forming only fuel gas manifold holes or oxidant gas manifold holes in each separator One of the manifold holes.

[0140] image 3 It is a plan view of the MEA holding frame 10, the anode separator 20', the cathode separator 30', and the isolation frame 40. The MEA holding frame 10, the spacer frame 40 and the single fuel cell ( Figure 1A ) in the same way.

[0141] on the other hand, image 3 The single fuel cell shown has an anode separator 20' and a cathode separator 30' in that it differs from a single fuel cell having an anode separator 20 and a cathode separator 30 (FIG. 1). That is, the fue...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com