Screening device for a plurality of single grade size of rock material and screening method thereof

A screening device and stone material technology, which is applied to chemical instruments and methods, screening, solid separation, etc., can solve the problems of difficult to guarantee particle size quality, multiple screening, heavy workload, etc., and achieve simple structure and high production efficiency Improvement, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manner of the present invention can be further understood through the following examples, but the present invention is not limited in any way.

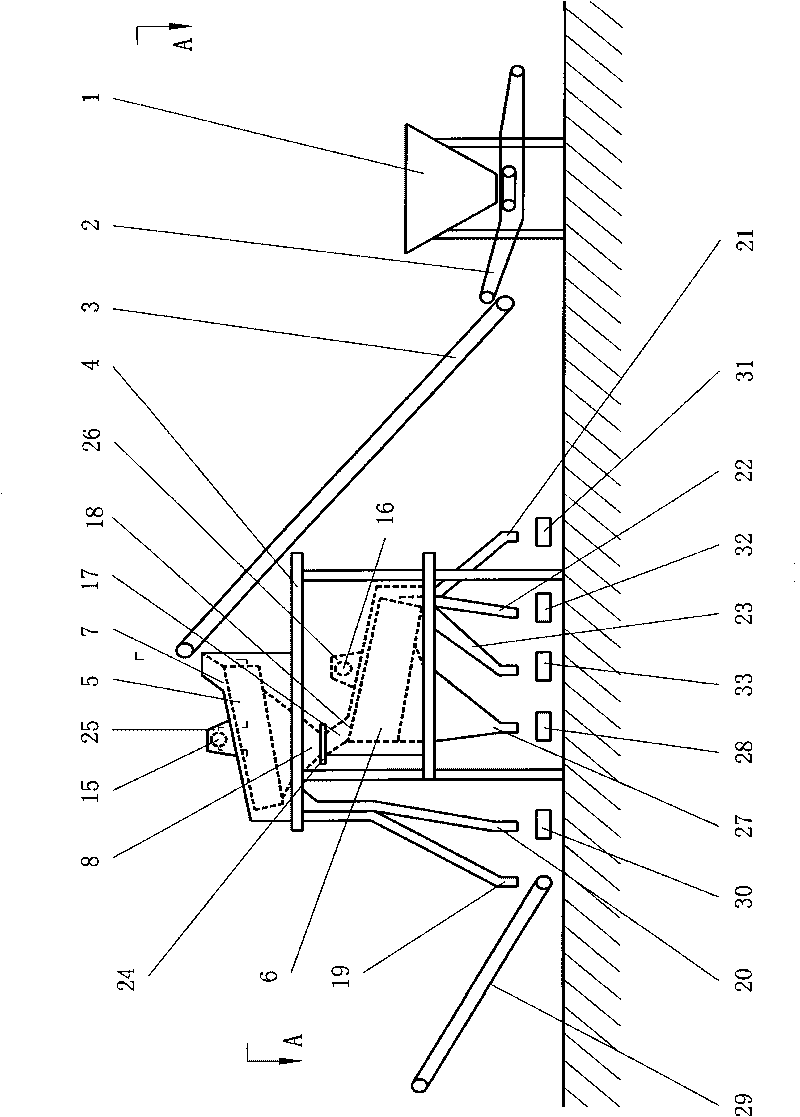

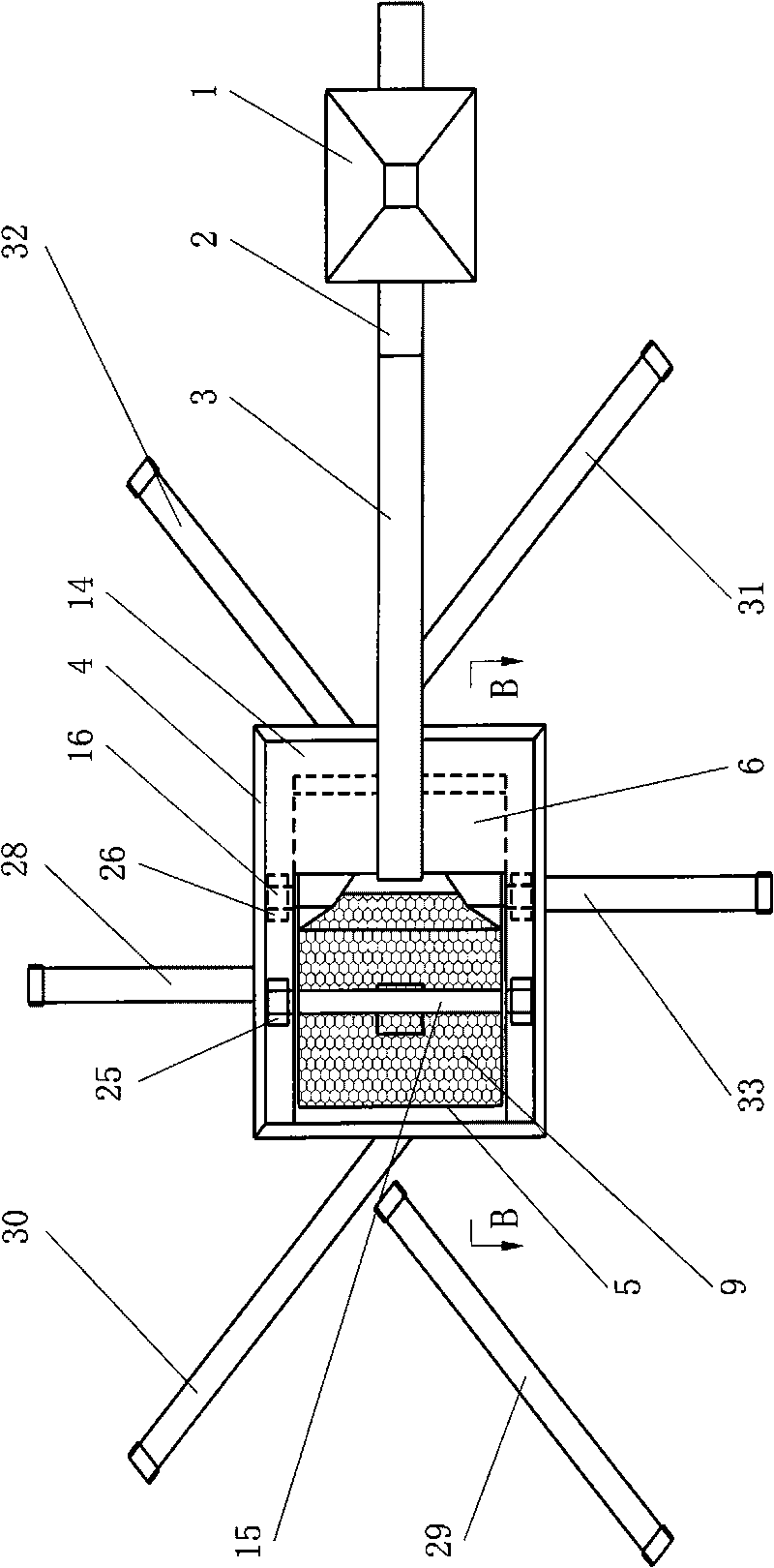

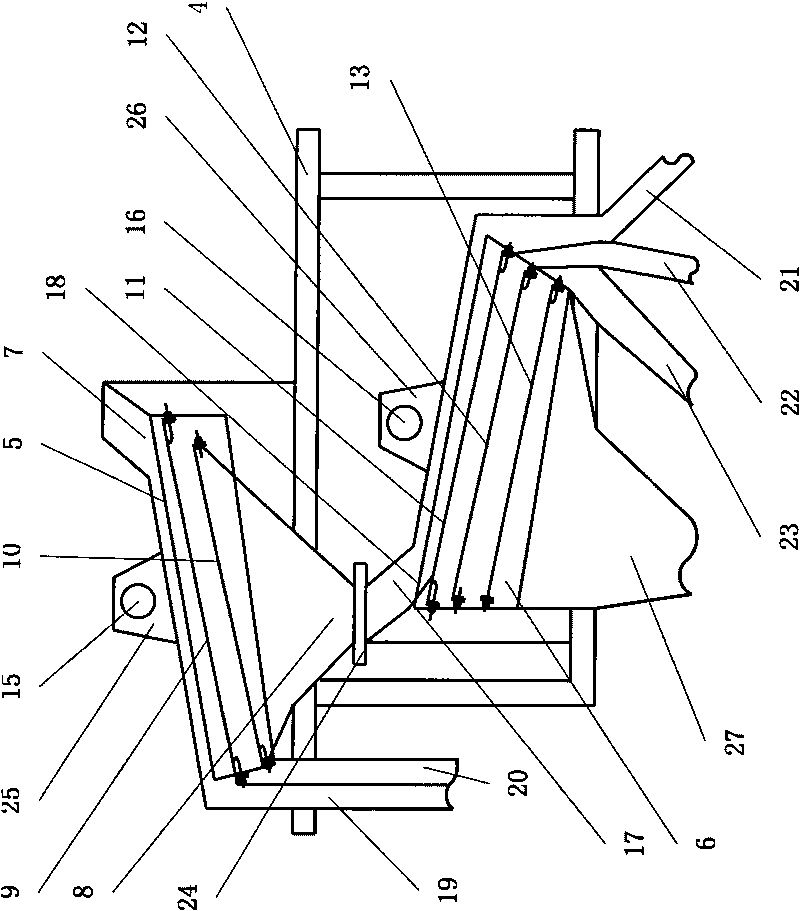

[0016] Such as figure 1 , figure 2 and image 3 shown.

[0017]When operating, first turn on the power, turn on the switch, use the loading machine to load the mixed stone into the mixed stone upper hopper 1, and the feeding conveyor 2 transports the mixed stone from the bottom of the mixed stone upper hopper 1 to the feeding belt conveyor 3 The lower part, the mixed stone material rises with the rolling of the feeding belt conveyor 3, until it is sent to the mixed stone material inlet 7 provided on the top of the upper screening bin of the upper screening machine 5, and the mixed stone material enters the upper screening bin and falls to the screen. On the first-stage screen 9 with a hole of 26.5 mm, the upper vibrating shaft 15 installed in the upper shaft seat 25 in the middle of the upper par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com