Air bearing structure and method for achieving air film thickness compensation

An air bearing and thickness compensation technology, which is applied to the parts of the instrument, the workbench, the instrument, etc., to achieve the effect of avoiding the change of posture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention is described in detail below in conjunction with accompanying drawing, to further understand the purpose, scheme and effect of the present invention:

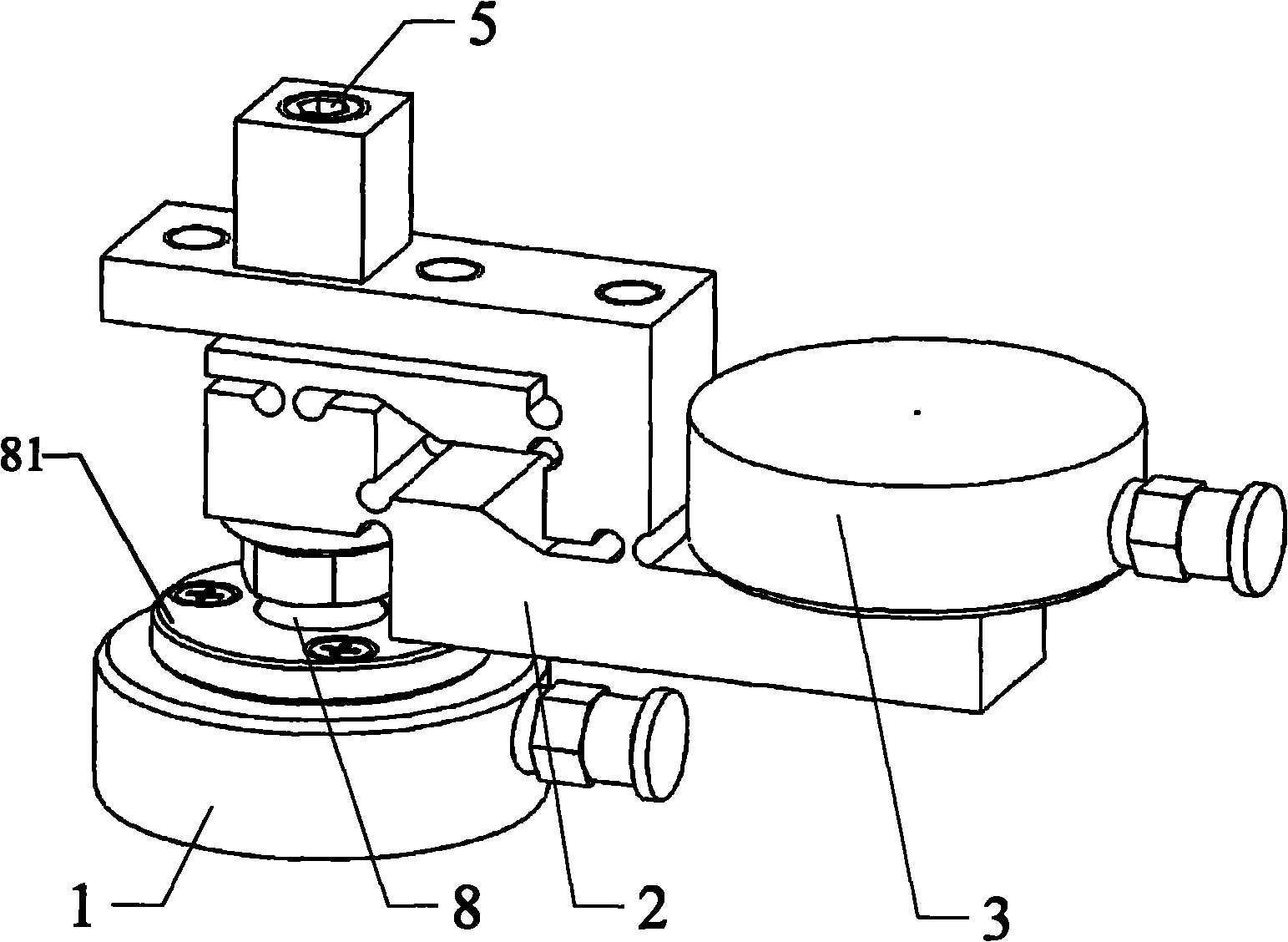

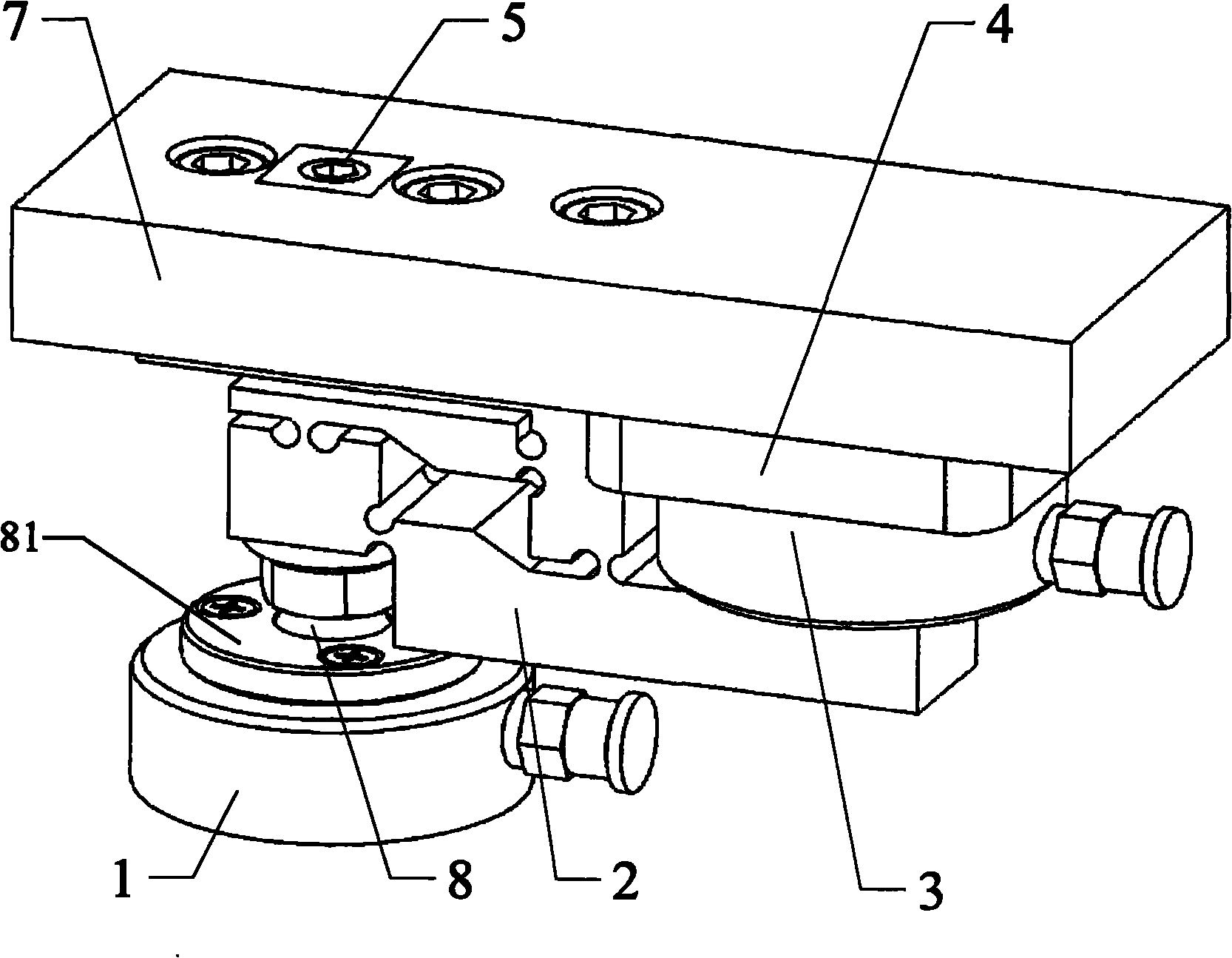

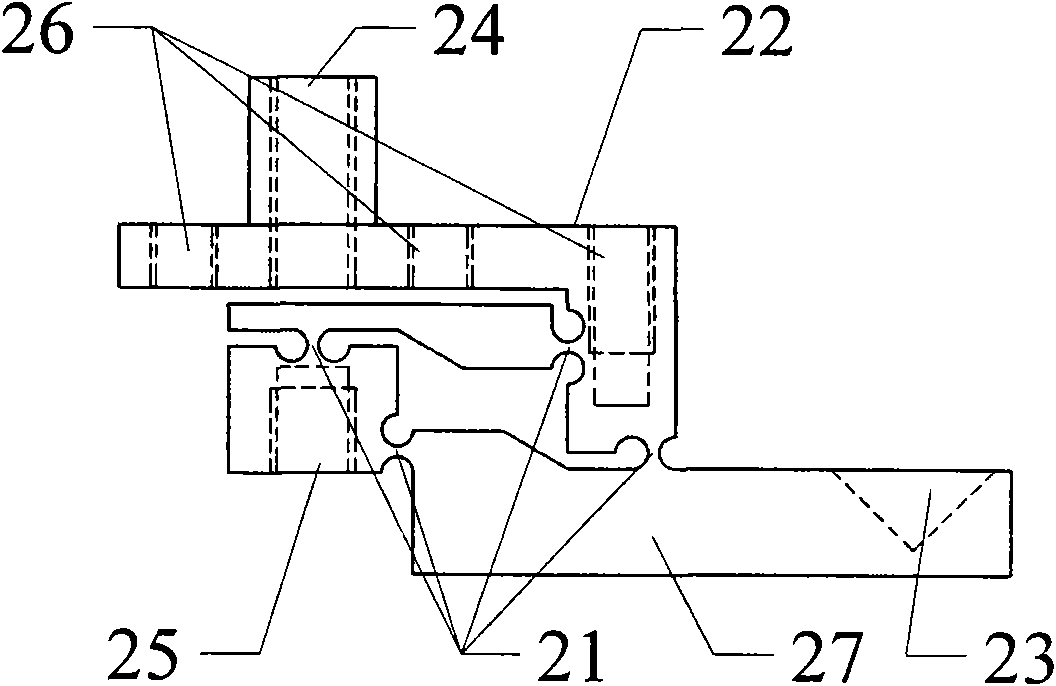

[0037] figure 1 and figure 2 Show the air bearing structure of the present invention, and its schematic diagram of assembly with the workbench, refer to figure 1 and figure 2 The air bearing structure with air film thickness compensation capability provided by the present invention is installed between an air bearing table 7 and a base to form a support. The air bearing structure includes: a working air bearing pad 1, a micro-displacement transmission mechanism 2, a compensation The air-floating pad 3 and the loading mechanism 5, wherein the micro-displacement transmission mechanism 2 is installed on the lower surface of the air-floating workbench 7; One end of the formed lever forms a lubricating air film between the compensating air-floating pad 3 and the air-floating workbench 7 during work;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com