Ink box of ink jet printer

An inkjet printer and printer technology, applied in printing and other fields, can solve problems affecting printing quality, easy damage and deformation of ink cartridge parts, etc., and achieve the effects of precise control, space saving, and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

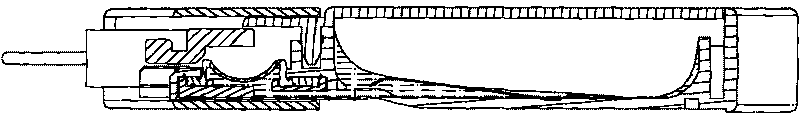

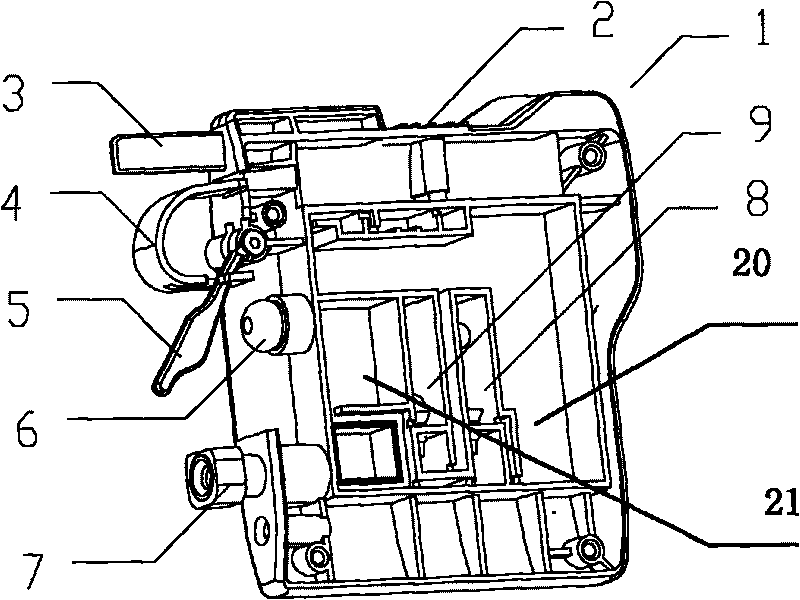

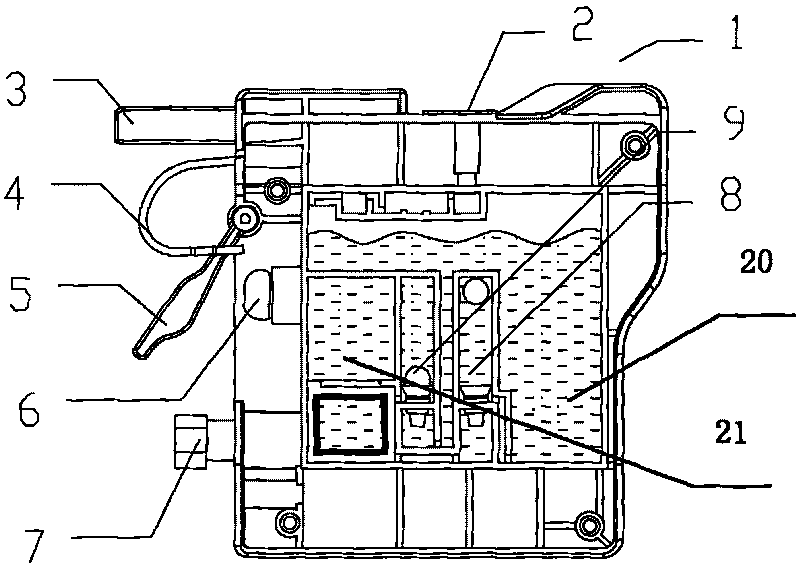

[0031] like figure 2 The shown ink cartridge for an inkjet printer includes a box body, a detection mechanism for detecting the ink cartridge and the remaining amount of ink, and the box body includes an ink storage chamber for storing ink and an ink outlet for supplying ink to the print head of the printer. port 7 and atmospheric inlet 2, the ink storage chamber includes a first ink chamber 20 and a second ink chamber 21, a gravity valve 9 and a buoyancy valve 8 are arranged between the first ink chamber 20 and the second ink chamber 21, and the gravity valve 9 and The buoyancy valve 8 cooperates to control the ink in the first ink chamber 20 to be consumed preferentially over the ink in the second ink chamber 21. The buoyancy valve 8 generates negative pressure only when the ink in the ink storage chamber prints to a certain amount. The atmospheric inlet 2 is set at on the first ink chamber 20 .

[0032] The detection mechanism for detecting the ink cartridge and the remai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com