Lost-foam pipe saddle

A lost foam, pipe saddle technology, applied in the direction of pipes, branch lines, pipes/pipe joints/fittings, etc., can solve problems such as unfavorable pipeline extension, redundant valve management, excessive pressure, etc., to speed up the construction progress and installation process. The effect of smooth and eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

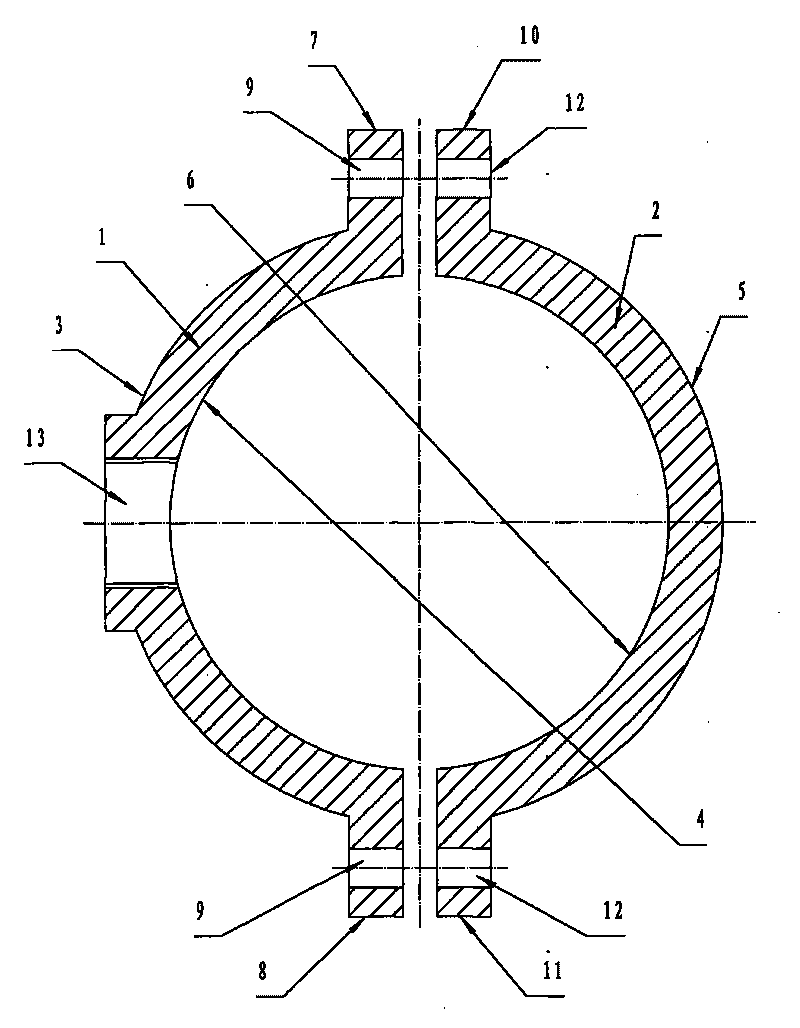

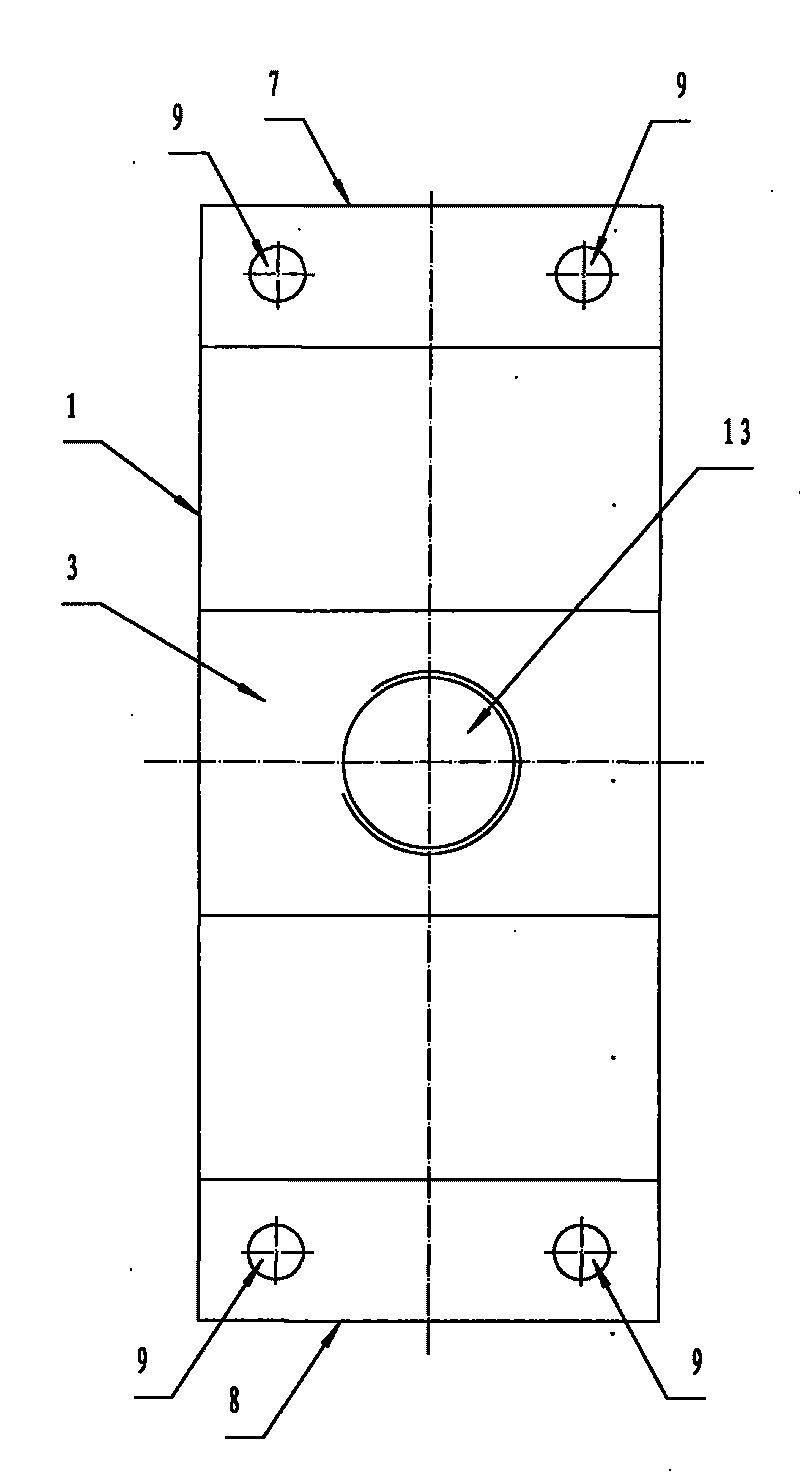

[0029] Embodiment 1: as Figure 1 ~ Figure 2 As shown, the lost foam saddle in this embodiment has a saddle base, which is characterized in that the saddle base is composed of a first semicircular saddle unit 1 and a second semicircular saddle unit 2 that cooperate with each other. The semicircular pipe saddle unit 1 has an outer pipe connection opening, a first semicircular pipe saddle outer surface 3 and a first semicircular pipe saddle inner surface 4, and the outer pipe connection opening runs through the first semicircular pipe saddle outer surface 3 and the first semicircular pipe Saddle inner surface 4, the second semicircular tube saddle unit 2 has a second semicircular tube saddle outer surface 5 and a second semicircular tube saddle inner surface 6, the first semicircular tube saddle inner surface 4 and the second semicircular tube saddle inner surface The surface 6 is relatively arranged, and the first semicircular saddle unit one end 7 and the first semicircular sa...

Embodiment 2

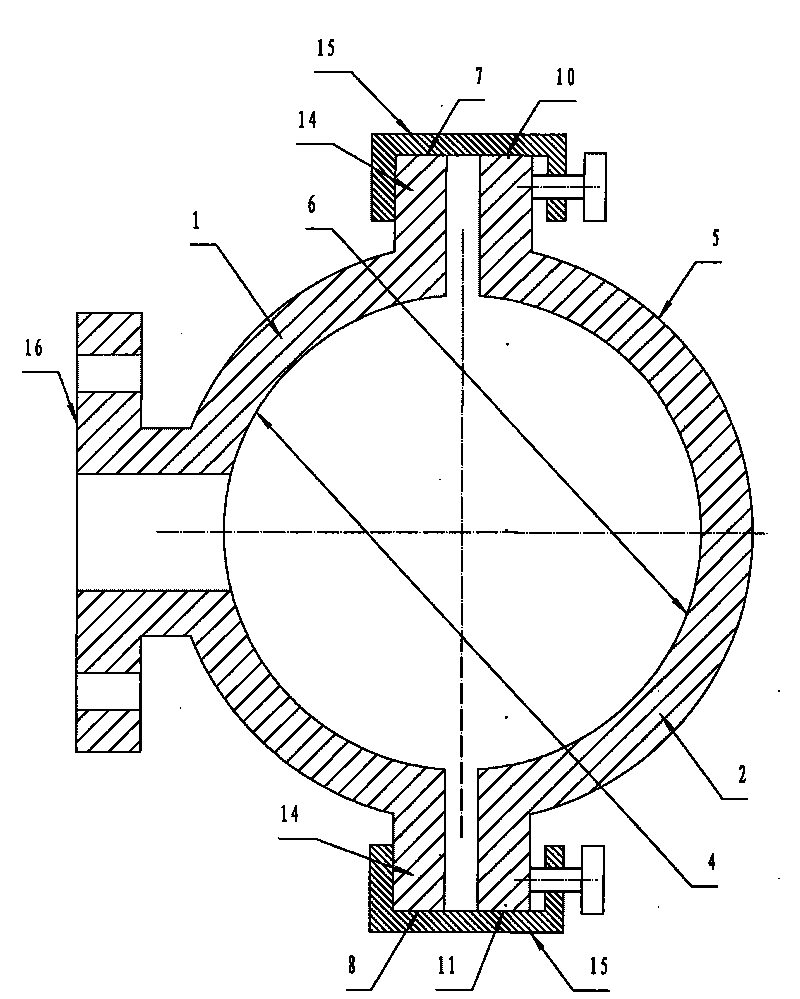

[0032] Embodiment 2: as Figure 3 ~ Figure 4 As shown, this embodiment is similar to Embodiment 1, except that the connection structure of the first semicircular saddle unit one end 7 and the first semicircular tubular saddle unit other end 8 is a snap-fit connection end 14, and the The connecting structure of the one end 10 of the second semicircular saddle unit and the other end 11 of the second semicircular saddle unit is a fastening connector 15 .

[0033] In this embodiment, the connection opening of the outer pipe is the connection opening 16 of the flange outer pipe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com