Automotive body center post with strengthening structure

A car body and reinforcement structure technology, applied in the direction of superstructure, superstructure sub-assembly, vehicle parts, etc., can solve the problems of easy deformation of the center pillar, small buffer area, crushing the occupants in the car, etc., and achieve impact force dispersion and protection Effects on head and shoulders, strengthening strength and stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

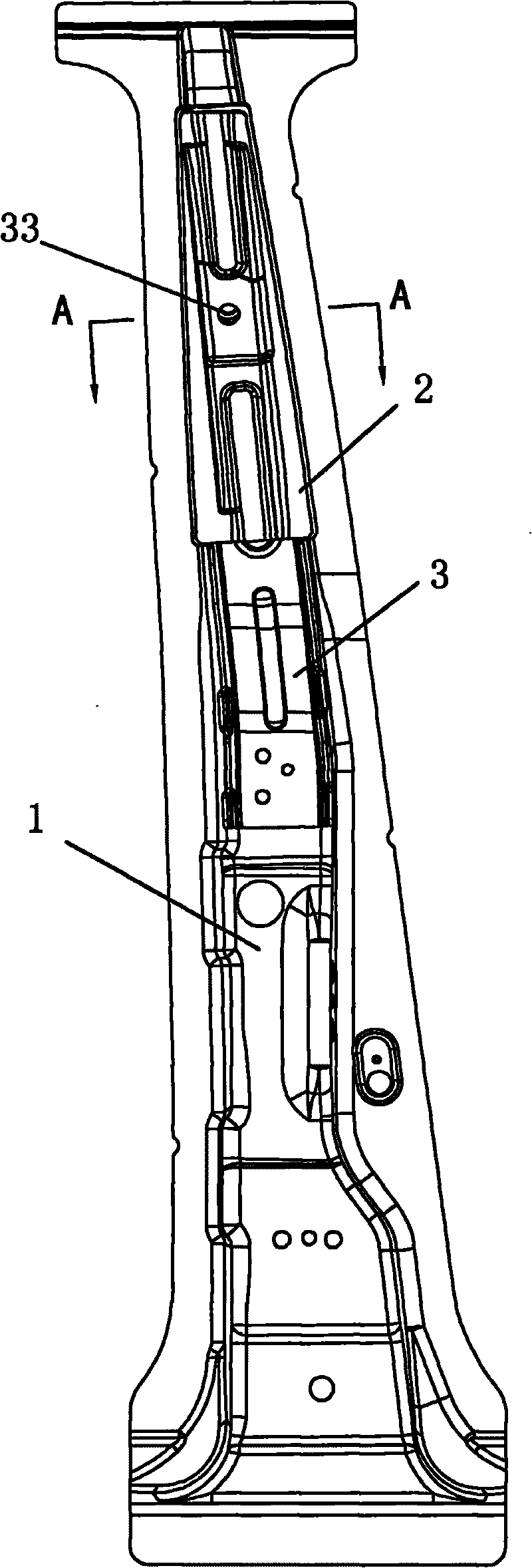

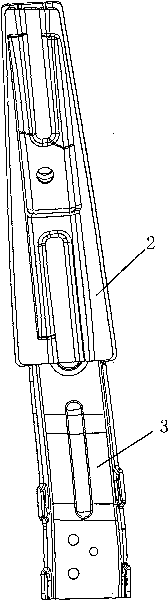

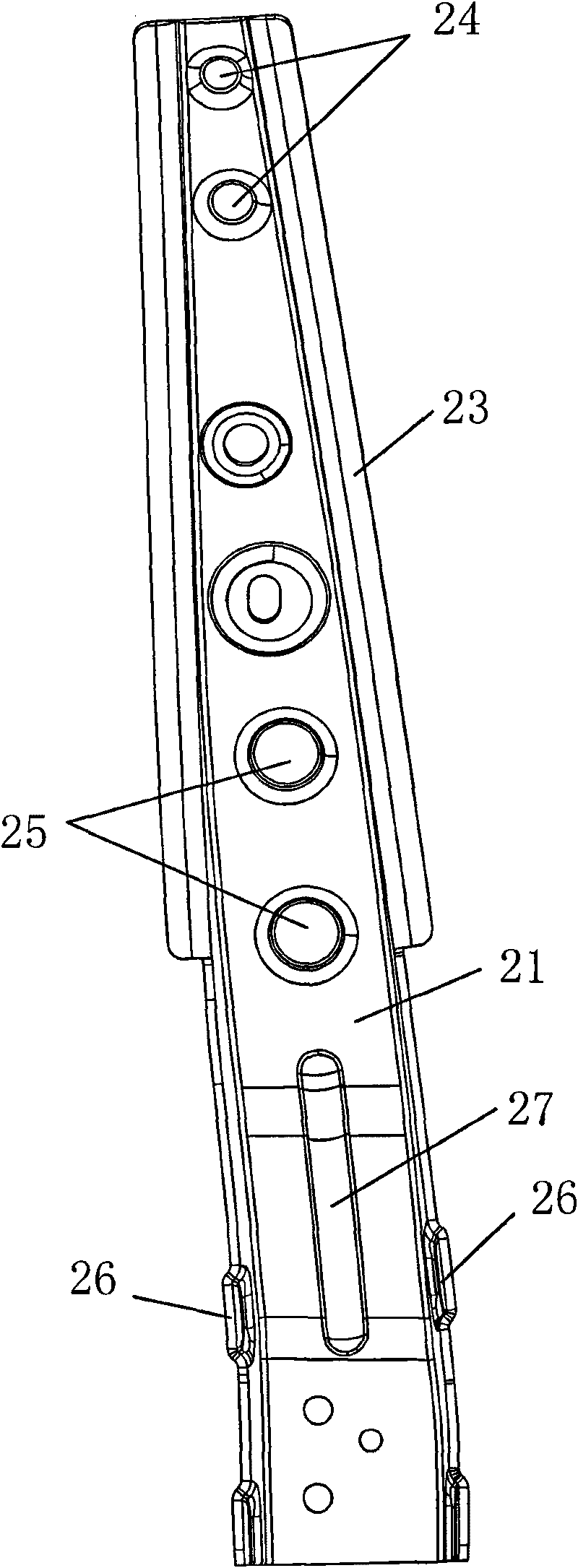

[0024] Such as figure 1 , figure 2 with Figure 8 As shown, the present invention is a center pillar of an automobile body with a reinforced structure, which is mainly composed of a center pillar reinforcement plate 1, a safety belt fixing reinforcement plate 2, a seat belt nut plate 3, a side wall outer plate 4 and a center pillar inner plate 5 . Among them, the side wall outer panel 4, the center pillar reinforcement plate 1 and the center pillar inner panel 5 are sequentially welded into one body. The notches of the outer panel 4 and the inner panel 5 of the center column are opposite to enclose the forming cavity, and the center column reinforcement plate 1 is welded between the side wall outer panel 4 and the inner panel 5 of the center column, and the center column reinforcement plate 1 is located in the cavity. The pillar reinforcement plate 1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com