Automatic calibration method between three-dimensional laser and monocular vision

A three-dimensional laser and monocular vision technology, which is applied in the direction of line-of-sight measurement, measuring devices, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

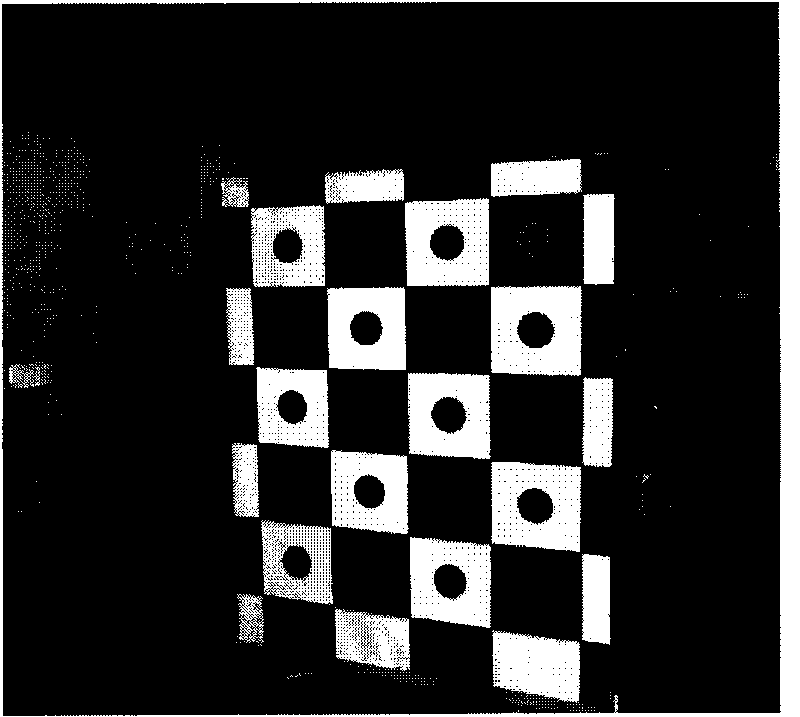

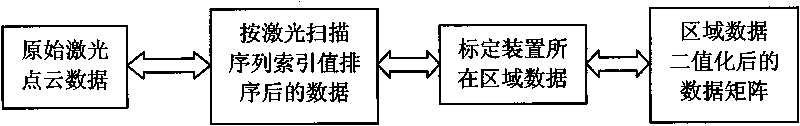

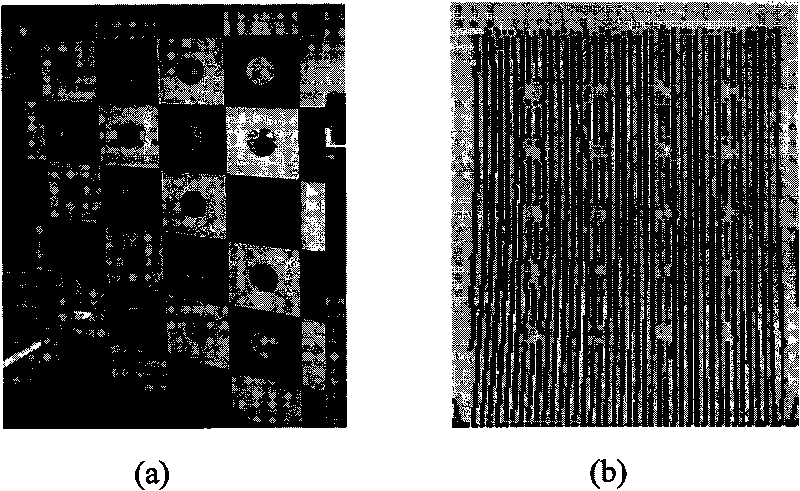

[0060] In order to verify the effectiveness of this method, the use of Figure 10 The constructed device was used for validation of the calibration method. SICK LMS 291 laser sensor is adopted, the plane scanning angle is 0-180 degrees, and the longitudinal range is dynamically adjustable, divided into 8 meters, 16 meters, 32 meters (distance resolution is 1 mm), 80 meters (distance resolution is 1 cm) four scanning ranges, the scanning range of 32 meters is used here. The gimbal motor has optional rotation angle resolutions, including: 0.192°, 0.288°, 0.480° and 0.960°. Here, 0.192° is selected, the starting angle is 30°, and the scanning range is 30°-130°. Use the motor to drive the laser sensor to obtain the three-dimensional laser ranging data of the scene. The size of the calibration device adopts a 4×5 bla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com