Floating ball funnel

A floating ball and funnel technology, which is applied in the field of experimental instruments, can solve the problems that the liquid cannot flow into the container, the liquid overflows, and the air cannot be discharged.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

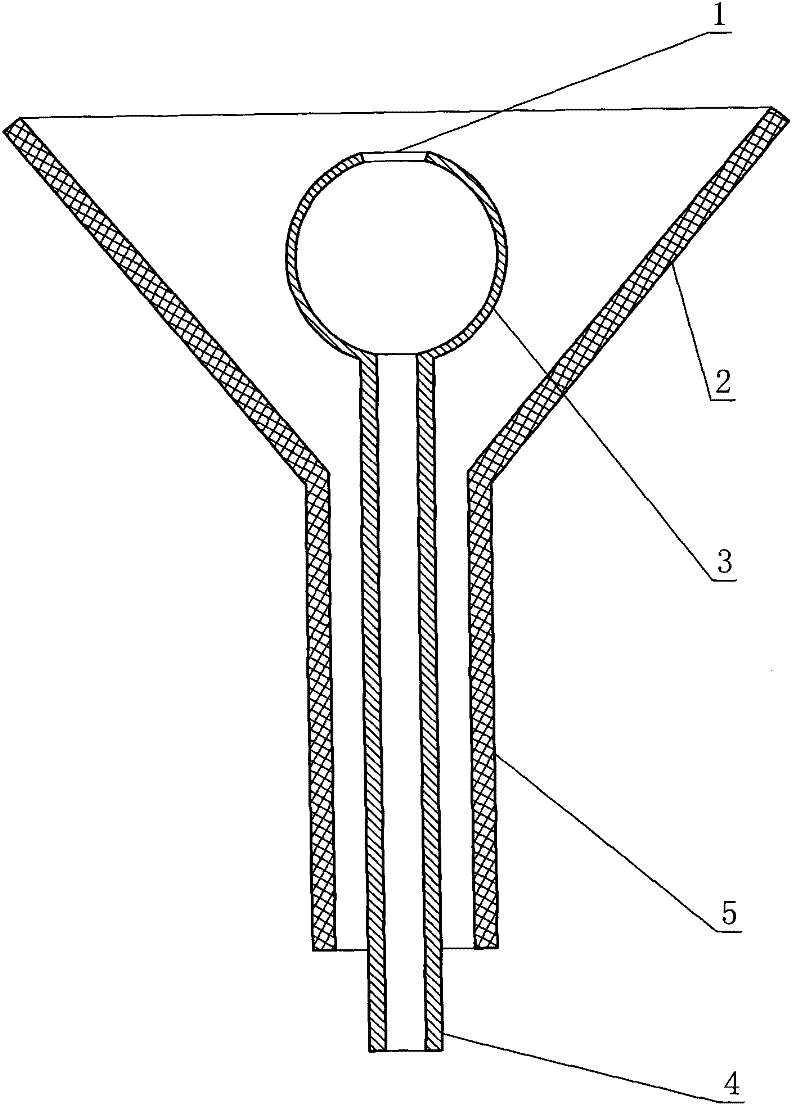

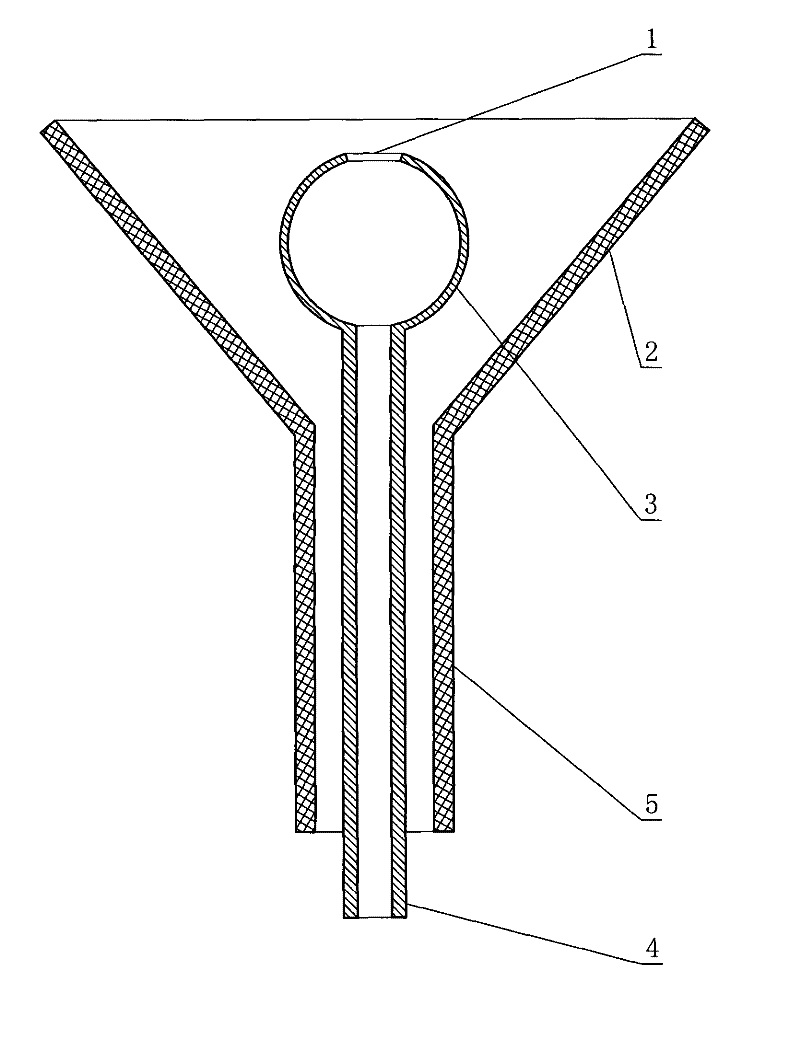

[0011] The float funnel is composed of an exhaust port 1, a tapered bucket 2, a float 3, an exhaust pipe 4 and a vertical pipe 5. The conical bucket 2 is an inverted conical shell, and the lower end of the conical bucket 2 is integrated with the cylindrical standpipe 5 . The circular tube-shaped exhaust pipe 4 is in the vertical pipe 5, and the top of the exhaust pipe 4 has a floating ball 3 which is integral with the exhaust pipe 4 and communicates with the exhaust pipe 4. The floating ball 3 is a spherical shell, and the top of the floating ball 3 has a The exhaust port 1 having a diameter larger than the inner diameter of the exhaust pipe 4 . The total length of the exhaust pipe 4 and the float 3 is greater than the total length of the tapered bucket 2 and the vertical pipe 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com