Big underground chamber tunneling method

A chamber and reverse technology, which is applied in the direction of earthwork drilling, mining equipment, tunnels, etc., can solve problems such as difficulty in climbing ladders, difficulty in manual slag removal, and unsafety. The effect of sexual problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific construction steps of the invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

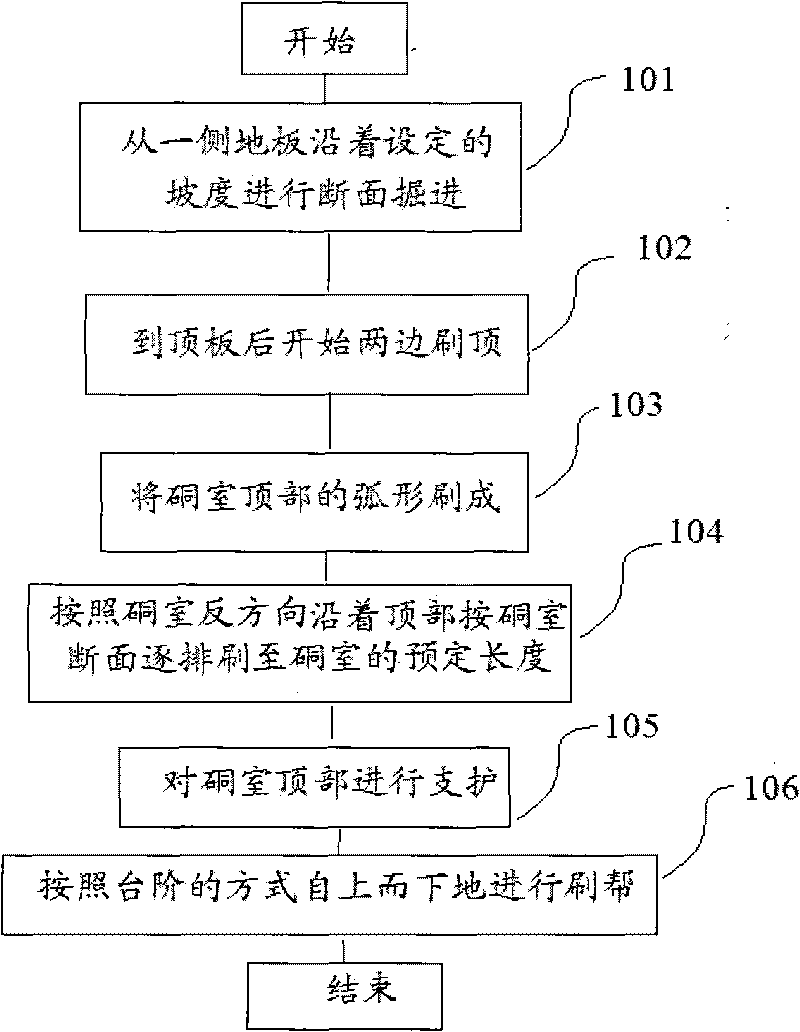

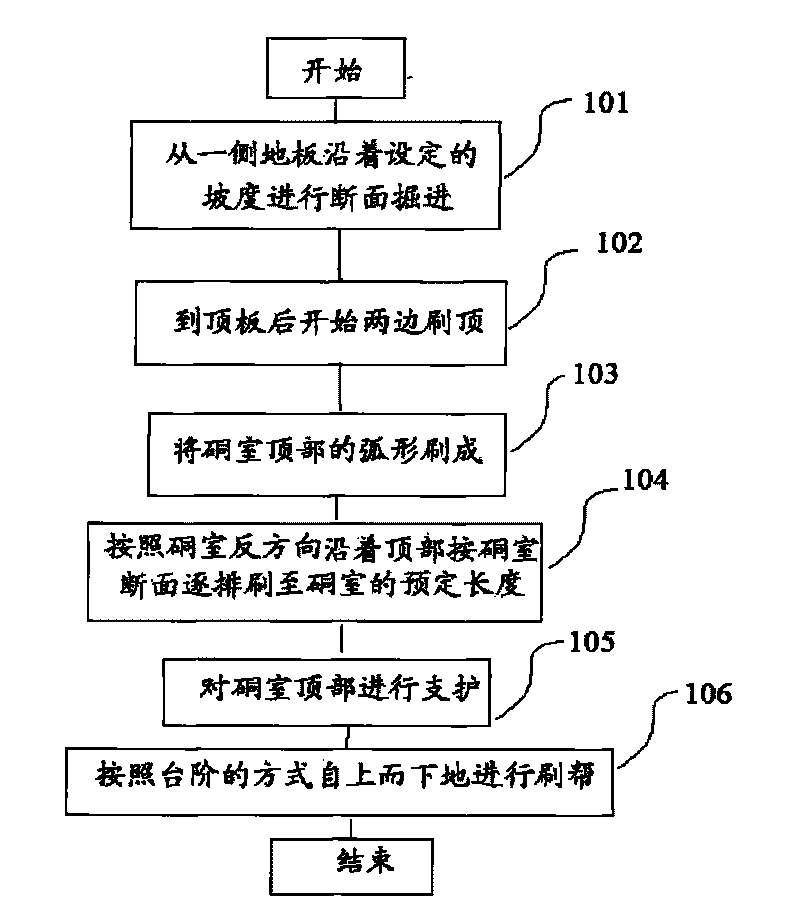

[0022] figure 1 It is the flow chart of the specific embodiment of this invention, and in a large amount of underground engineering practices, it is generally recognized that, tunnel and underground cavern engineering, its core problem, all boils down on the two key processes of excavation and support, namely How to excavate can be more conducive to the stability and support of the cave; if support is required, how to support can more effectively ensure the stability of the cave and facilitate excavation.

[0023] The above two factors determine that in the excavation construction of the chamber, it is necessary to adopt a corresponding construction method according to the characteristics of the chamber. In the embodiment, the large chamber described has a large span, a high height, and poor safety , if the whole s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com