Vortex-street flow sensing measuring method and special sensor

A vortex flow, sensing measurement technology, applied in the field of flow sensors, can solve the problem of interference, which is not well solved, affects the measurement of the lower limit of the flow, and has a small piezoelectric sheet design. It achieves high electromechanical conversion efficiency, eliminates influence, The effect of improved signal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The embodiments of the present invention will be described in detail below in conjunction with the drawings.

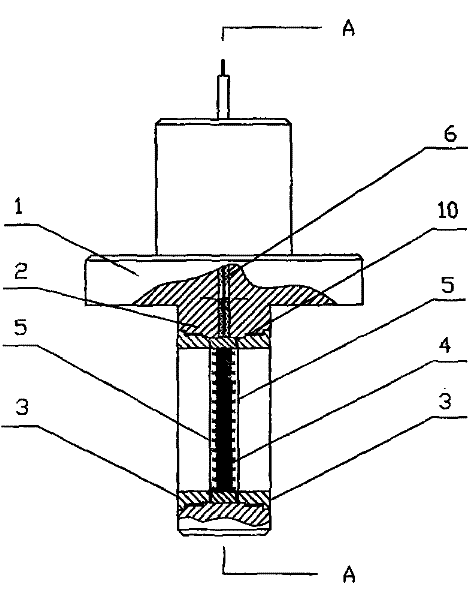

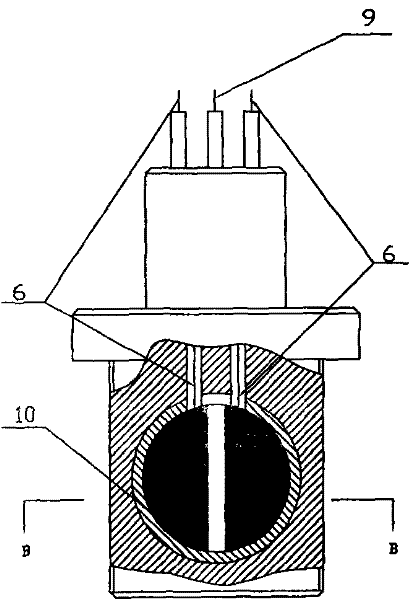

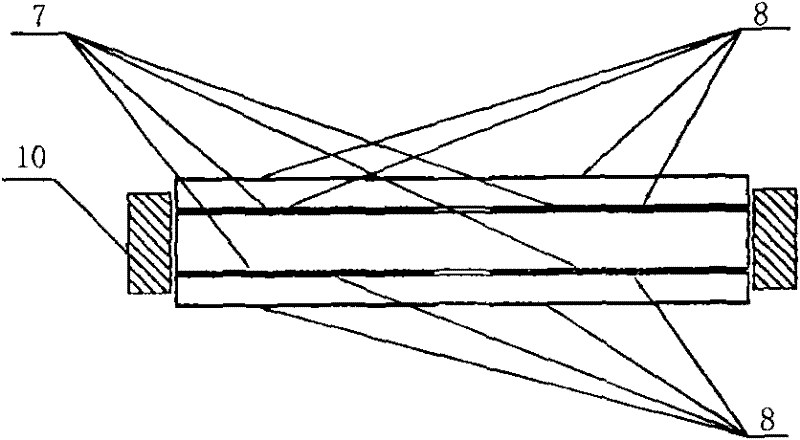

[0011] The present invention is a vortex flow sensor for measuring gas, liquid, steam and other media, such as figure 1 As shown, it mainly includes a base 1, a mounting base 2, and a piezoelectric signal generating device. The base 1 is cylindrical, and the mounting base 2 is strip-shaped, and the two adopt a structure that integrates precision pressing parts. Such as figure 2 As shown, the mounting seat 2 is provided with a communicating mounting hole, and the mounting hole is arranged vertically to form a vertical cylindrical hole. Such as figure 1 As shown, the piezoelectric signal generating device is composed of a circular insulating sheet 4 in the middle and circular piezoelectric sheets 5 on both sides, forming a structure of two piezoelectric sheets 5 wrapping the middle insulating sheet 4, and the circumference is surrounded by a ring 10 sets to make it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com