Method and device for testing whole-vehicle reliability of electric motor train units

A technology of EMUs and testing methods, applied in the direction of railway vehicle testing, etc., can solve problems such as insufficient work, achieve the effect of promoting quality, improving operation service quality, and promoting continuous improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

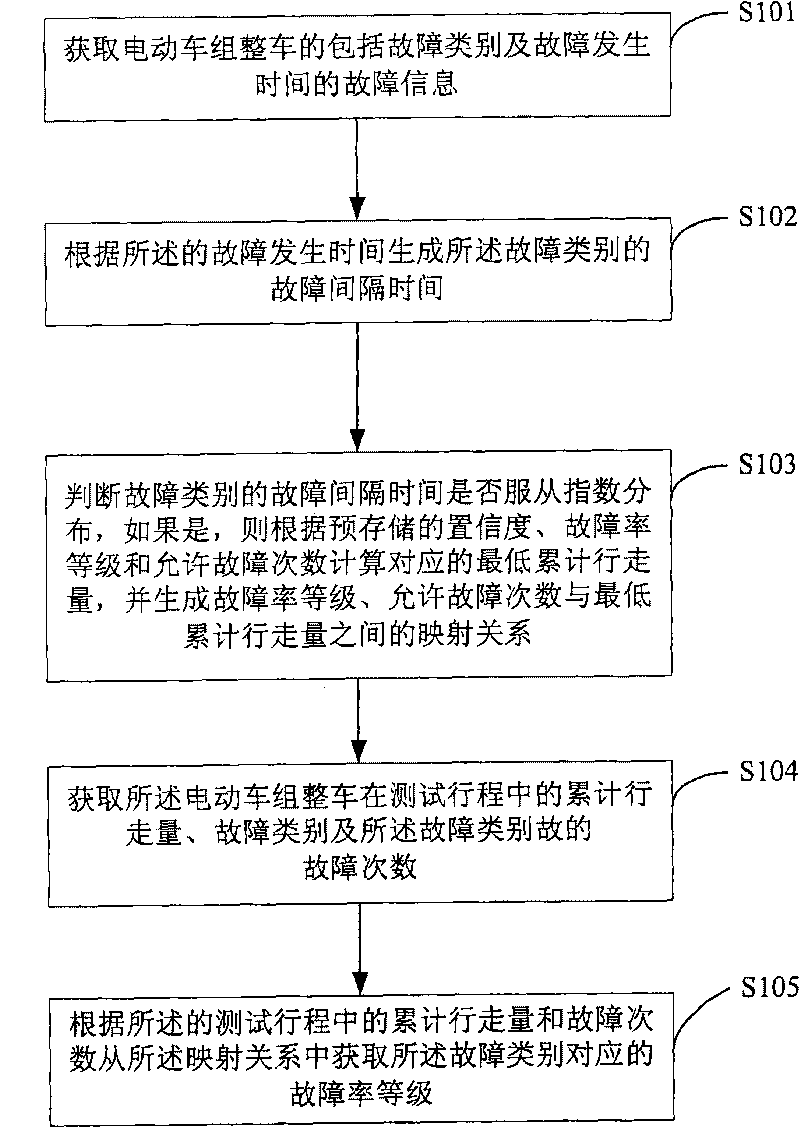

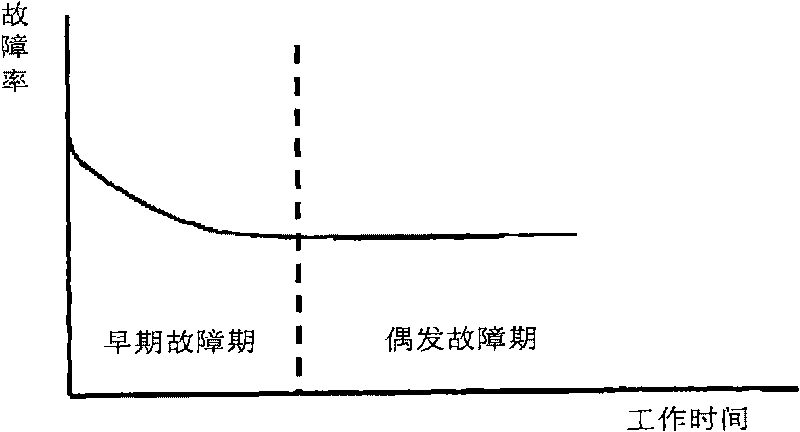

[0051] Figure 4 It is a flow chart of the method of Embodiment 1 of the whole vehicle reliability test of the electric train unit of the present invention. Wherein steps S401~S403 are the same as figure 1 Steps S101 to S103 shown are mainly used to judge whether the EMU has entered the sporadic failure period with stable quality. Only when the EMU is in the sporadic failure period and its failure rate is constant can the reliability test be performed. Then calculate the corresponding minimum cumulative travel amount according to the pre-stored confidence level, failure rate level and allowable number of failures, and generate a mapping relationship between the failure rate level, allowable failure times and the minimum accumulated travel amount. In this embodiment, the minimum cumulative walking distance is the minimum cumulative walking mileage, and the unit is 10 6 km.

[0052] Figure 5 It is the recommendation table of the failure rate level of the EMU according to th...

Embodiment 2

[0067] Figure 7 It is a flow chart of the method of Embodiment 2 of the reliability test of the whole electric train unit of the present invention. Wherein steps S701~S703 are the same as figure 1 Steps S101-S103 shown are mainly used to judge whether the EMU has entered the sporadic failure period with stable quality. Only when the electric locomotive is in the sporadic failure period and its failure rate is constant can the reliability test be performed. Then calculate the corresponding minimum cumulative travel amount according to the pre-stored confidence level, failure rate level and allowable number of failures, and generate a mapping relationship between the failure rate level, allowable failure times and the minimum accumulated travel amount. In this embodiment, the minimum cumulative walking distance is the minimum cumulative walking mileage, and the unit is 10 6 km. In this embodiment, the mapping relationship between the failure rate level and the failure rate l...

Embodiment 3

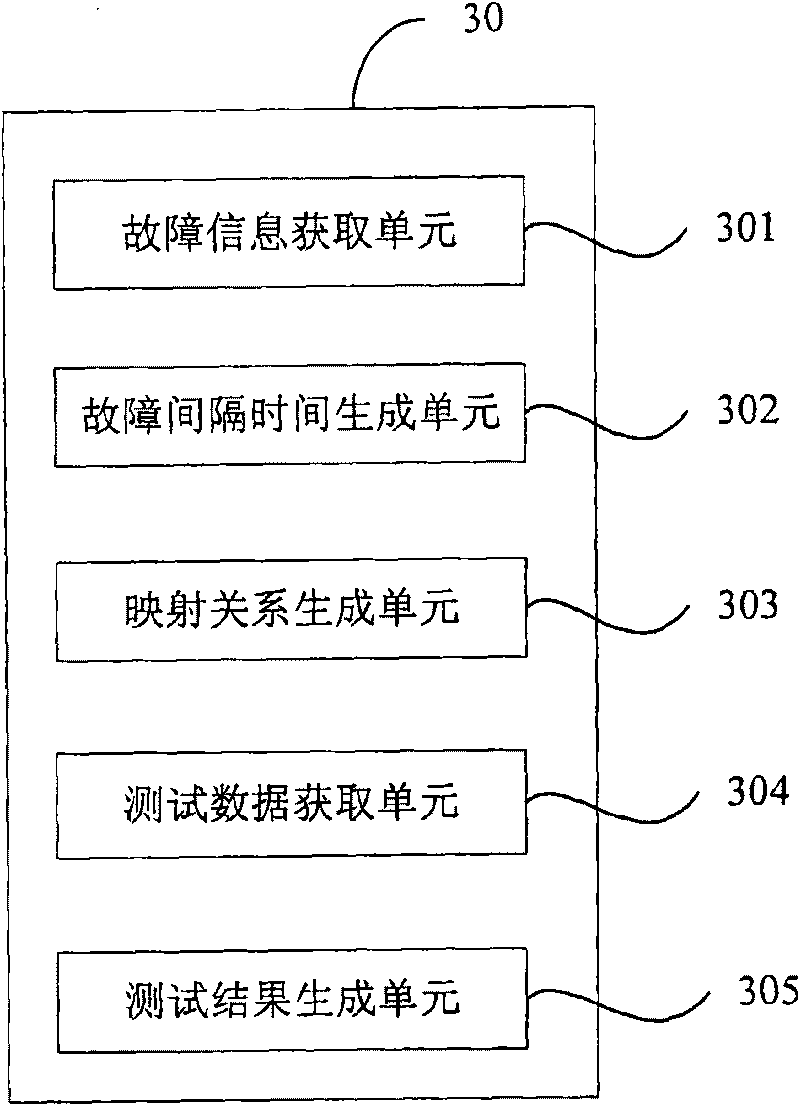

[0075] Figure 8 It is a structural flow chart of Embodiment 3 of the whole vehicle reliability test of the electric train unit of the present invention. In this embodiment, the EMU monitoring equipment 10 is used to provide the EMU vehicle reliability testing device with the fault information of the EMU vehicle, and is also used to provide the EMU fault category, Fault information such as accumulated mileage and fault occurrence times.

[0076] The database device 20 is used to pre-store parameter information such as confidence level, failure rate level, target failure rate level and allowable number of failures. These parameter values can be adjusted according to the overall condition and actual quality of the EMU during actual application.

[0077] The reliability test device 30 for the complete vehicle of the electric multiple unit obtains the fault information such as the cumulative mileage, the number of failures and the parameter information such as the confidence le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com