Grid-shaped airflow guiding device used for cooling large-sized annular cast

A technology of airflow guiding and annular casting, applied in the field of casting heat treatment equipment, can solve the problems of low cooling efficiency, stress concentration, cracks, etc., and achieve the effect of saving repair welding and orthosis, rapid and uniform cooling, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0015] The present invention will be described in detail below with reference to the drawings and specific embodiments.

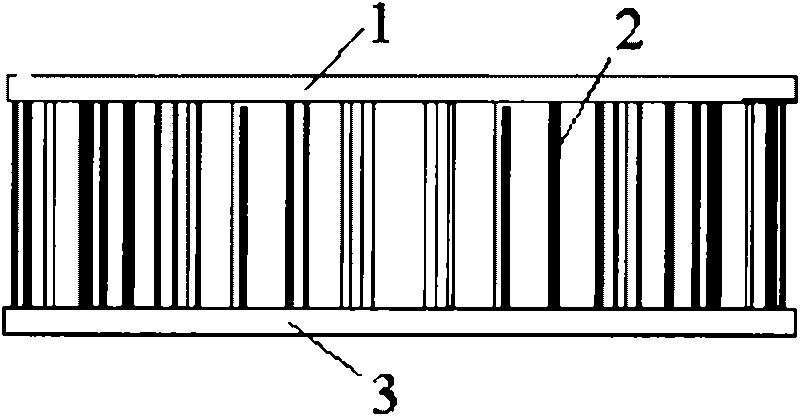

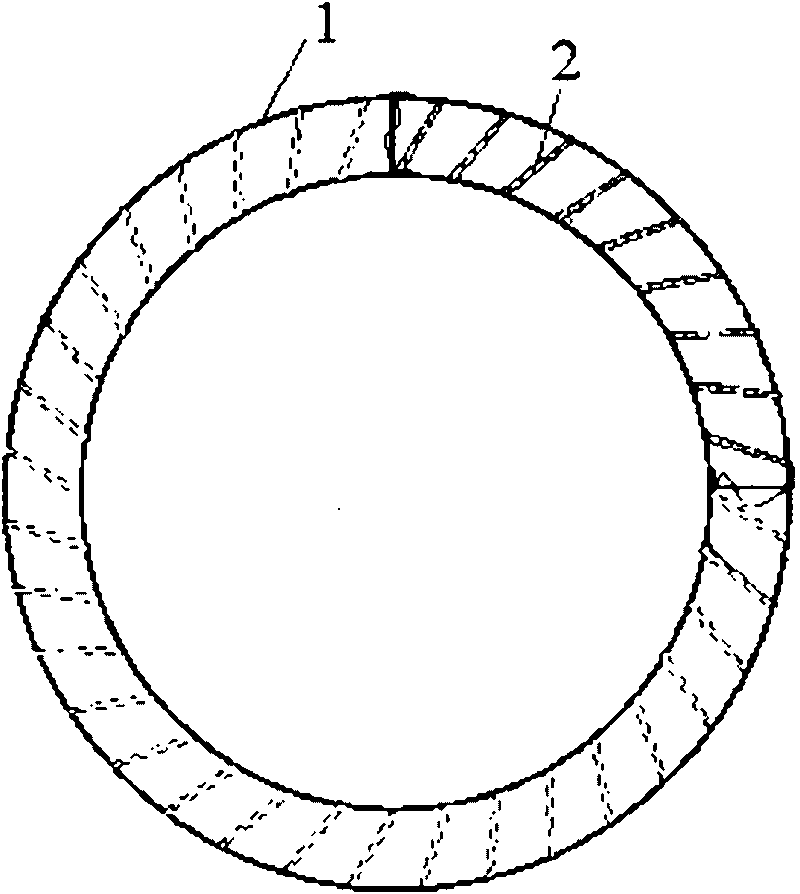

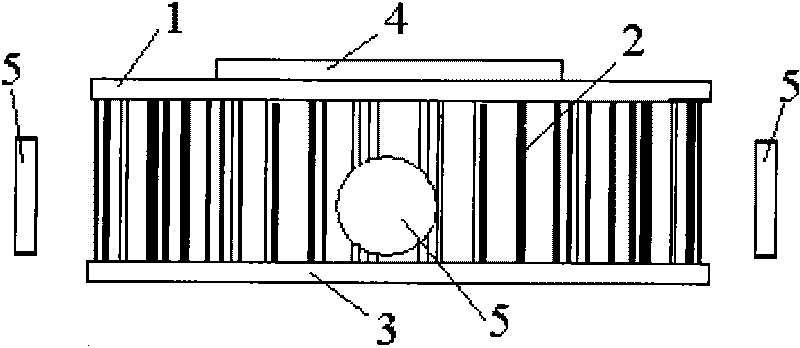

[0016] Such as figure 1 As shown, the air flow guiding device provided by the present invention can make the air flow evenly act on the casting, and make the casting uniform and rapid cooling. The structure of the device includes an annular first connecting plate 1 and an annular second connecting plate 3 arranged in parallel. The first connecting plate 1 and the second connecting plate 3 have the same structural size. The first connecting plate 1 and the second connecting plate The plate 3 is connected by at least one blade 2, and the two ends of the blade 2 are respectively connected to the first connecting plate 1 and the second connecting plate 3 by screws. The blades 2 are evenly distributed along the circumferential direction of the connecting plate, and the width of the blade 2 is 200mm~ 800mm, 500mm≤ height of blade 2< height of casting.

[0017] The nu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap