Device and method for purifying mycelial fungi polluted by bacteria

A filamentous fungus and bacterial contamination technology, which is applied in the field of fungal devices, can solve the problems of poor bacteria removal effect, and achieve the effect of cheap production materials, easy access to production materials, and simple production methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

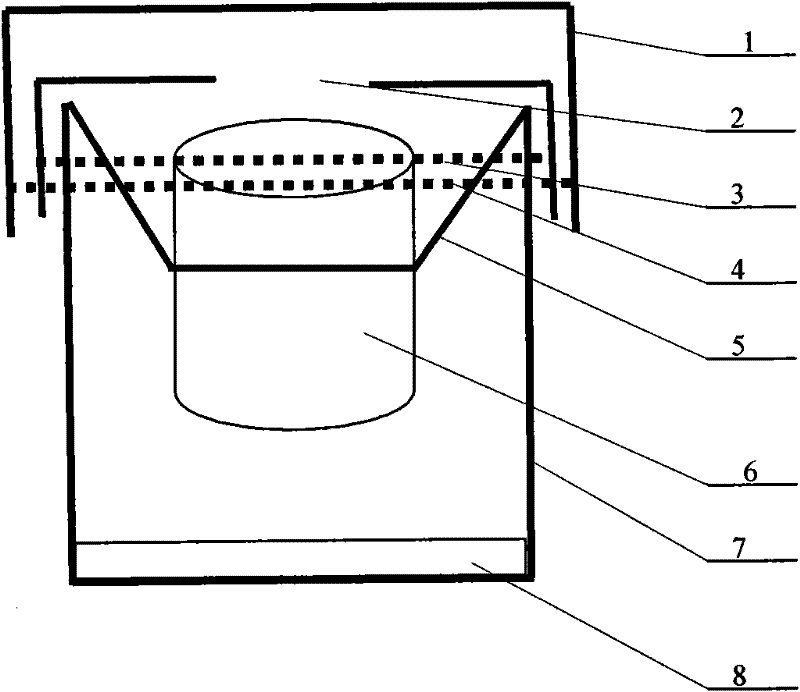

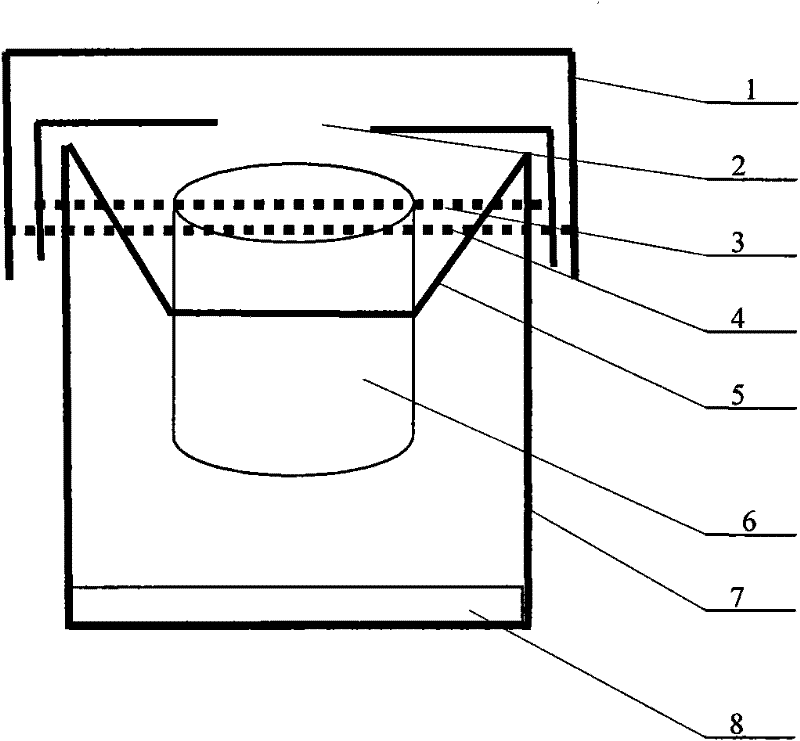

Image

Examples

Embodiment 1

[0022] 1 Make a purification device

[0023] (1) Preparation of purified fungal collection layer: choose potato to prepare plant tissue extract. Peel the potatoes, cut into small cubes of about 1.0cm×1.0cm, add water to boil according to the ratio of potatoes to tap water 1:5~10 (W / W), boil for 30 minutes, filter the decoction with gauze, add water Reach the original amount of water, and then mix and dissolve according to the ratio of potato decoction: sucrose: agar in the ratio of 100:2:1.5 (W / W), and then the solid fungal culture medium is obtained, that is, the purified fungal collection layer. Sterilize as soon as possible after the preparation is completed, sterilize at 115°C for 30 minutes before use, or refrigerate for a short time (1-5°C) for later use. .

[0024] (2) Prepare fungal culture fluid: compared with solid fungal culture medium, just do not need to add agar, namely press potato decoction: sucrose is prepared with the ratio of 100: 2 (W / W) to obtain fungal ...

Embodiment 2

[0030] Similar to Example 1, the difference is the manufacturing method of the biological purification column 6 . Use perlite tap water to boil for 10 minutes, then dry or air dry, add 1:1 (W / W) fungal culture solution, stuff it into a 1.5-2.5cm thick high-temperature-resistant plastic tube, and use a high-temperature-resistant plastic net at the bottom end of the tube Encased to prevent perlite from flowing out, purified fungi can be obtained by this method.

Embodiment 3

[0032] Similar to Example 1, the difference is the preparation method of the solid fungal culture medium and the fungal culture solution. Take soybean sprouts and grind them, squeeze out bean sprouts juice with a cloth, add bean sprouts juice, sugar and tap water in a ratio of 1:5:100 to make a fungal culture solution, and select common edible sucrose. Add 2% (W / W) agar to the fungal culture solution to make a solid fungal culture medium. Purified fungi can be obtained using this method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com