Grating type trenchless prop excavating equipment and trenchless prop method tunnel excavating process

A non-excavation and grating technology, applied in mining equipment, tunnels, earthwork drilling and mining, etc., can solve problems such as easy formation of cavities, complicated cutterhead replacement, roof collapse, etc., to reduce adverse effects, reduce safety risks, eliminate void effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

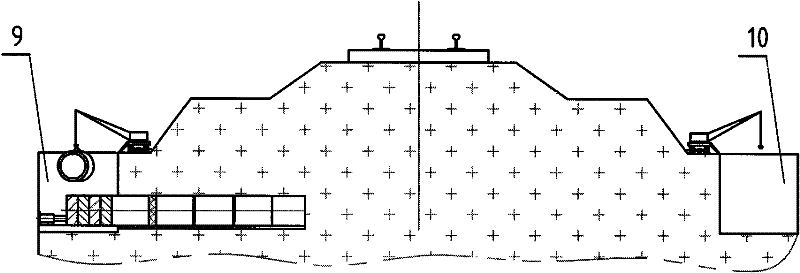

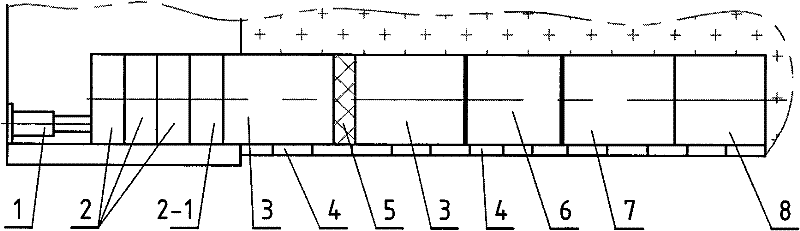

[0046] Example 1 as Figure 1-10 Shown: a grid-type trenchless pipe jacking equipment, including pipe jacking cylinder 1 and its hydraulic station, concrete pipe 3 and crane, and also includes circular outer jacking iron 2, sheath 5, and pipe jacking force The device 6, the guiding concrete pipe 7, the working head 8 for grid top punching and the guide rail 4 arranged under the working head 8 for grid top punching.

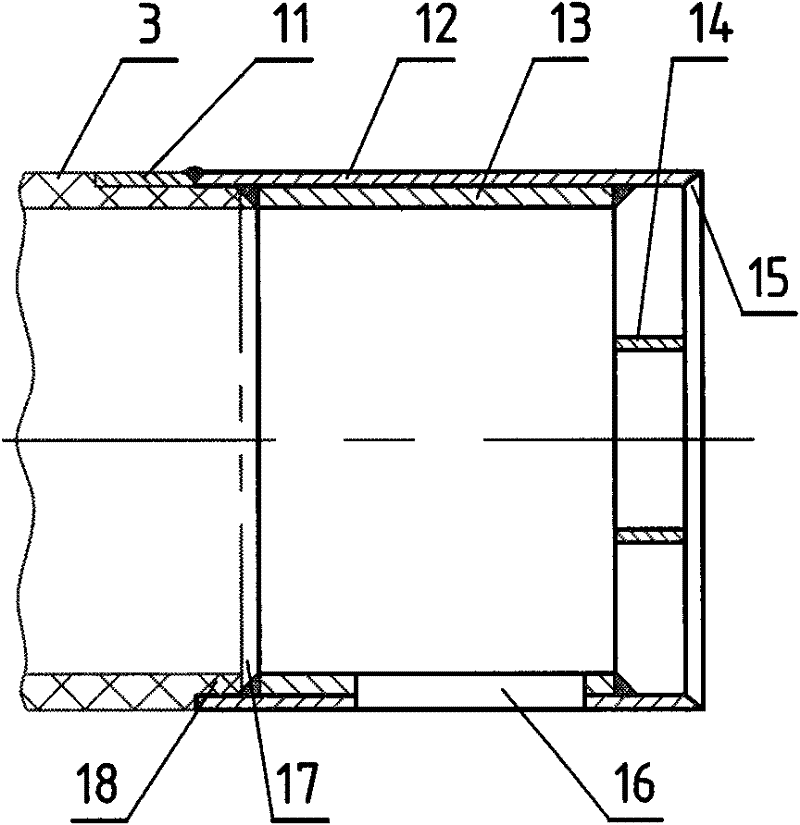

[0047] The grid top punching working head 8 is composed of a top punch outer ring 12, a top punch inner ring 13 and a grid 14 welded together, and the outer diameter of the top punch outer ring 12 is equal to the outer diameter of the concrete pipe 3. The inner diameter of the top punch inner ring 13 is equal to the inner diameter of the concrete pipe 3; one end surface of the top punch outer ring 12 perpendicular to the axis is provided with a knife edge 15, and the grid 14 is connected to the inner side of the top punch outer ring 12 with a knife edge and the to...

Embodiment 2

[0053] Example 2 as Figure 11-12 Shown: piston rod top iron 21, oil cylinder top iron 24, circular outer top iron 2 or the flat joint of concrete pipe 3 end faces include a conical flat joint with a sealing ring 29 at one end and a flat joint with a steel ring 28 at the other end, The outer diameter of the steel ring 28 is equal to the outer diameter of the concrete pipe 3 , and the inner diameter of the steel ring 28 is matched with the conical flat mouth joint with the sealing ring 29 .

Embodiment 3

[0054] Example 3 as Figure 5 Shown: the forward punch type top punch working head 20 is made up of the forward punch type top punch outer ring 19 , the top punch inner ring 13 and the grid 14 which are welded together, and the grid 14 may not be assembled. One end face of the front punch top punch outer ring 19 and the axis at an angle of α = 60° is provided with a knife edge 15, the grid 14 and the inner side of the front punch top punch outer ring 19 with a knife edge end and the top punch inner ring 13 The ends are welded as a whole; the other end of the forward-type top punch outer ring 19 and the top punch inner ring 13 perpendicular to the axis forms a concave groove 17, and the concave groove 17 is connected with the guide concrete pipe 7. Concrete convex groove 18 cooperates socket. The front punch type top punch working head 20 is not provided with the transparent rectangular window 16 described in Embodiment 1, and the guide rail 4 can be laid under the protection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com