Large tunnel traverse measuring device and installing and debugging method thereof

A mobile measurement, installation and debugging technology, applied in the direction of measuring device, aerodynamic test, machine/structural component test, etc., can solve the problems of time-consuming, large measurement range, etc., to improve efficiency, reduce labor intensity, reduce The effect of turning on and off frequencies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

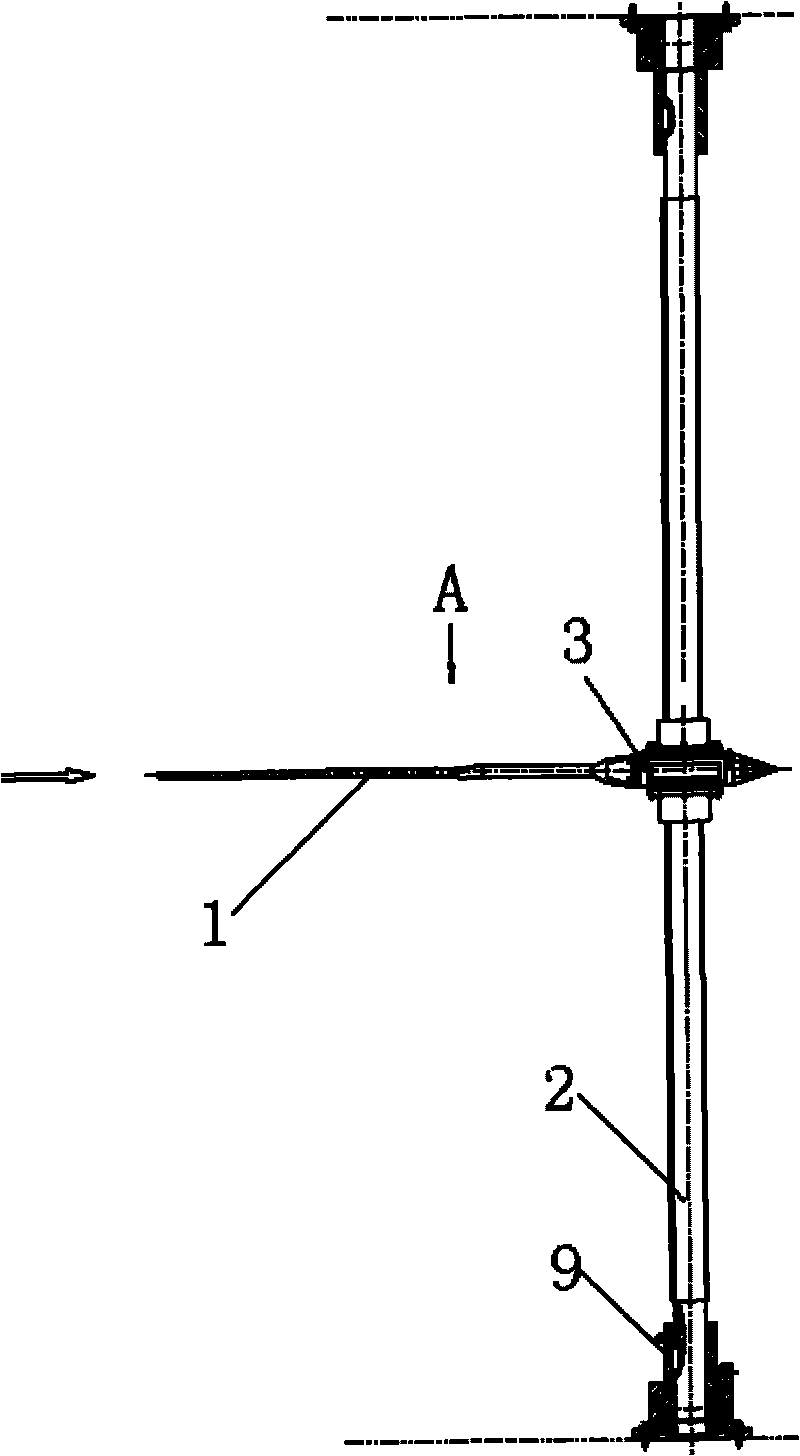

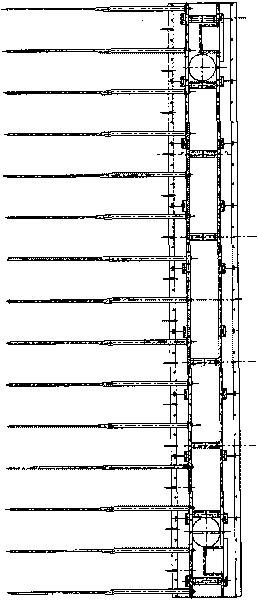

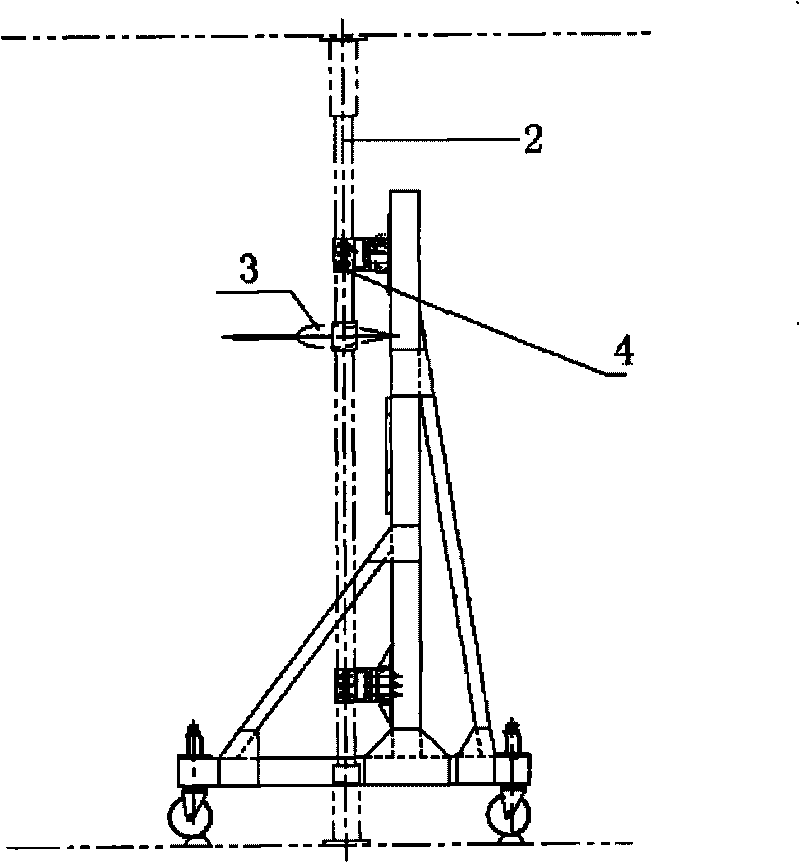

[0026] Such as image 3 As shown, the two transmission support screws 2 are respectively fixed with the tooling frame through the chuck 4, as shown in Figure 4 As shown, the bottom of the tooling frame is provided with adjustable four anchor rods 5 . Such as figure 1 As shown, the measurement rake 3 is connected to the probe 1, which is the prior art. Measuring rake 3 is contained on the two transmission support lead screws 2, and can move up and down along the two transmission support lead screws. The upper and lower ends of the transmission support screw 2 are installed in the connection seat 9, such as Figure 5 As shown, the lower part of the coupling seat 9 is located in the base 11 and is mounted on the angular contact joint bearing 10 . Such as Figure 6 , Figure 7 As shown, a driving device is installed on the measuring rake, and the driving device includes a motor 12, a worm 13, and a worm nut 14. The worm 13 is driven by the motor 12, and the worm 13 drives t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com