Flat-type automobile wiring harness fastener

A kind of automotive wiring harness, flat type technology, applied in the direction of pipe brackets, electrical components, pipes/pipe joints/pipe fittings, etc., can solve problems such as unfavorable cost control and design, increased wiring harness costs, wiring harness changes, etc., to ensure performance and control costs , smooth wiring and fastening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings of the description.

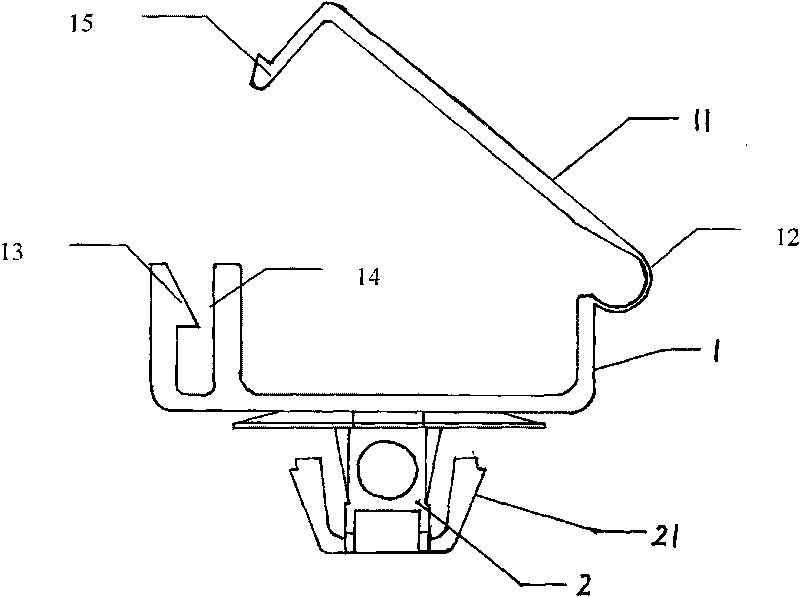

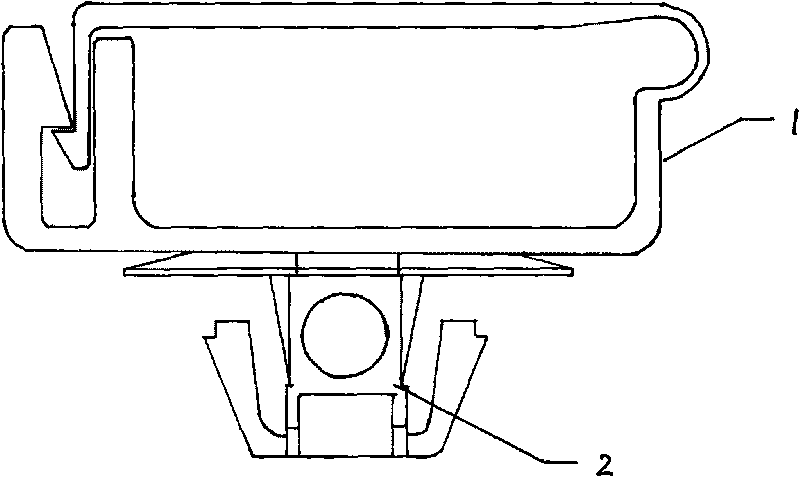

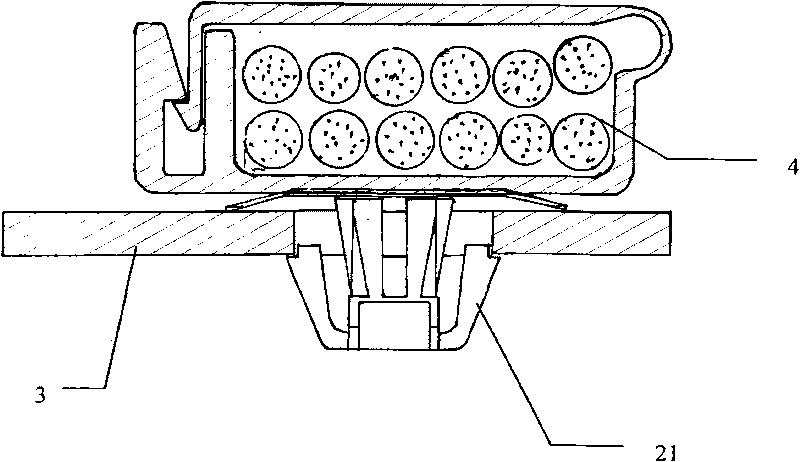

[0014] see figure 1 and figure 2 , the wire harness buckle is made of plastic, and the buckle is divided into upper and lower functional parts. The upper part is the buckle body 1, which is used to buckle the wire harness, and the lower part is the elastic chuck 2, which is used to snap into the hole on the body sheet metal. The upper and lower parts are integrally formed.

[0015] The buckle body 1 is a flat rectangular frame, the center of which is a horizontally connected buckle space, the upper frame of the flat rectangular frame is a flip-out buckle 11, and one end of the flip-out buckle 11 is connected to the top of one side frame The connection part is a soft connection part 12 formed by thinning the material, so that the flip-out buckle 11 can easily rotate around the connection part 12 . There is a bar...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap