Built-in cold wall type shift reactor for heat exchanger and direction connection structure for shift reactor and downstream heat exchanging equipment

A technology for heat exchange equipment and reactors, applied in chemical instruments and methods, hydrogen separation, separation of hydrogen using solid contact, etc., can solve the problems of leakage source, pipeline material manufacturing, high inspection cost, large investment amount, etc. External piping, complete adiabatic reaction, and the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

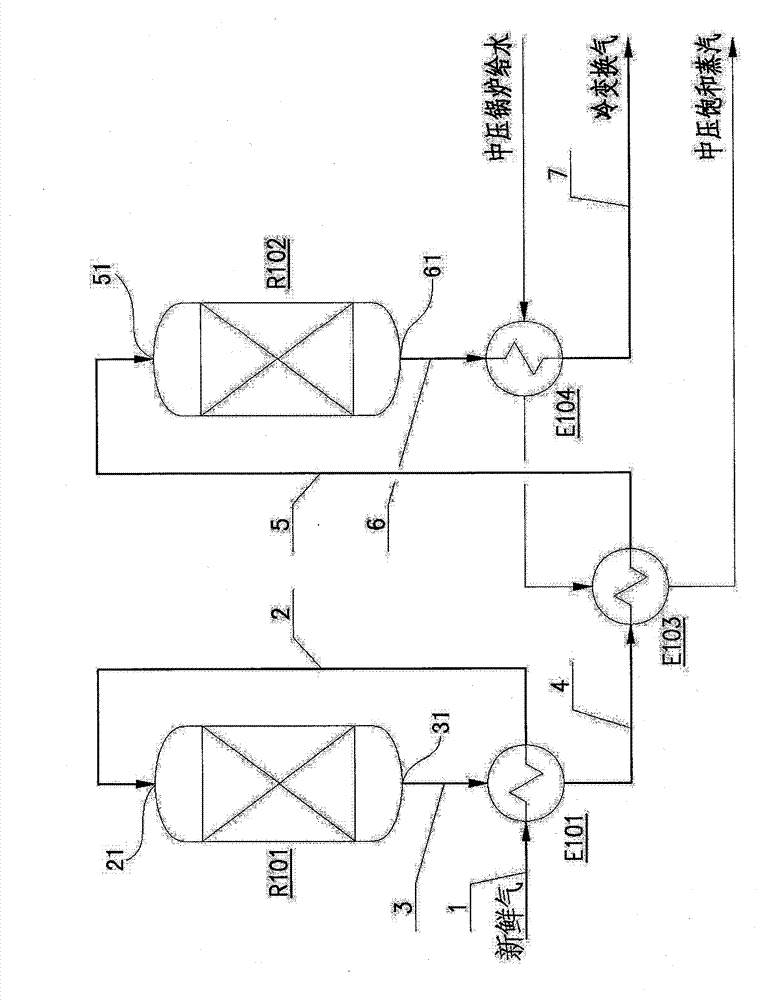

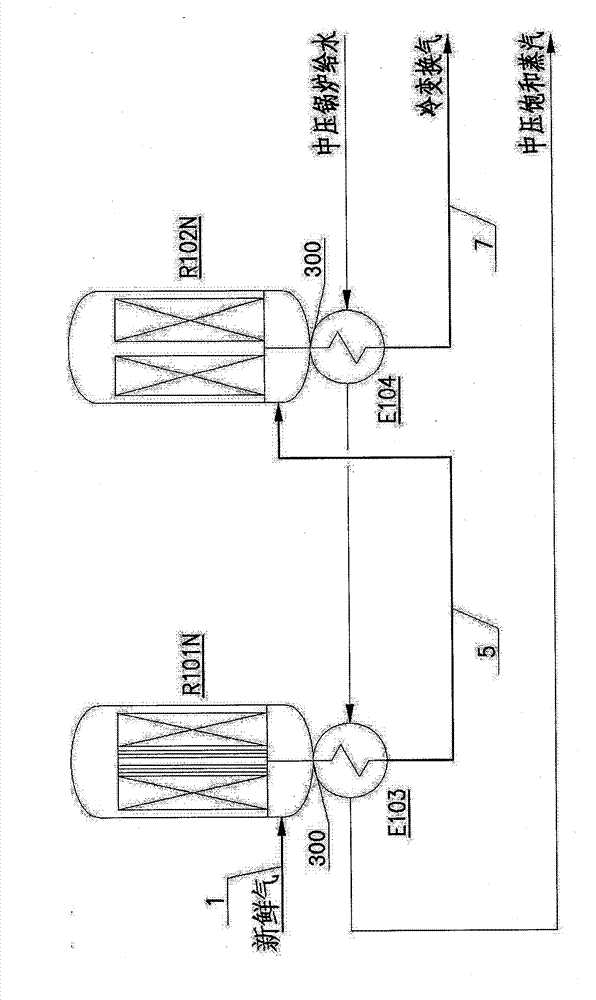

Problems solved by technology

Method used

Image

Examples

Embodiment 1

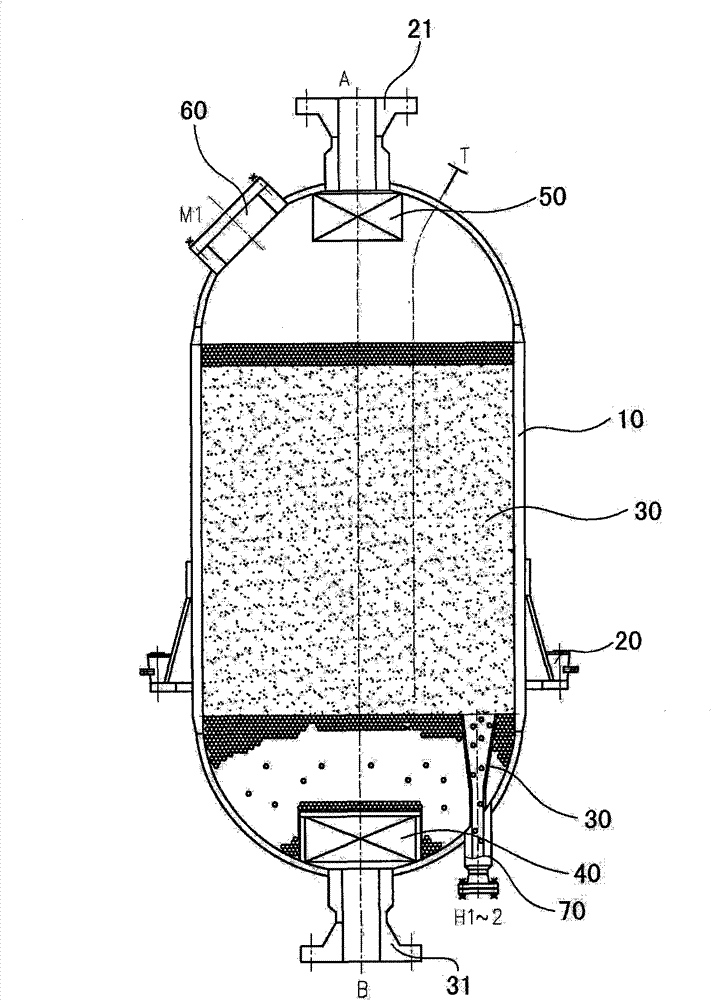

[0052] see image 3 , the cold-wall shift reactor with a built-in heat exchanger shown in the figure is an axial radial reactor, including a pressure-bearing shell 100, which is welded by a cylinder section and upper and lower heads The cylinder section and the upper and lower heads are all made of medium-temperature hydrogen-resistant steel, and there is no need to use stainless steel lining in the pressure shell 100 . The entire pressure-bearing housing 100 is installed on a foundation using a support 110 (not shown in the figure). On the top of the pressure housing 100 , that is, on the top of the upper head, a manhole 120 and a starting heating gas inlet 130 are arranged. The purpose of setting the manhole 120 is to facilitate the disassembly and assembly of the heat exchange component 200 and the outlet central pipe 300 . A manhole cover 121 is installed on the manhole 120 , and a pressure gauge P is installed on the manhole cover 121 to detect the reaction pressure in t...

Embodiment 2

[0061] see Figure 4 , the cold-wall shift reactor with built-in heat exchanger in this embodiment is an axial reactor, and its structure is based on the same principle as that of Embodiment 1, the only difference is that the position of the feed gas inlet 150 of the shift reactor is different, and the feed gas is in the The direction of flow in the tubes is reversed. This embodiment is not only another structural form of the axial-to-radial conversion reactor, but also due to the inversion of the feed gas flow direction, when the reactor adopts an axially reversed structure, the cold wall between the pressure-bearing shell and the catalyst outer frame The channel structure is realized.

[0062] The cold-wall shift reactor with a built-in heat exchanger includes a pressure-bearing shell 100. The pressure-bearing shell 100 is welded by a cylinder section and upper and lower heads, and the cylinder section and the upper and lower heads are all made of Made of medium-temperatur...

Embodiment 3

[0074] see Figure 5 , the cold-wall shift reactor with built-in heat exchanger of this embodiment is an axial radial reactor, and its structure is basically the same as that of Embodiment 2, the only difference being that: a radial gas dispersion is arranged on the catalyst outer frame 410 The hole 411 makes the catalyst outer frame 410 double as a gas distributor.

[0075] The working principle of this embodiment is: the low-temperature feed gas enters the feed gas guide tube 220 of the heat exchange component 200 from the feed gas inlet pipe 150a of the shift reactor, and enters the column of the heat exchange component 200 through the feed gas guide tube 220 In the tube, it exchanges heat with a part of the heat-shifted gas from the catalyst bed 400. After the heat-exchanged raw material gas reaches the activation reaction temperature of the catalyst, it enters the lower space of the pressure shell 100 through the tubes, and then passes through the reactor. The row holes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com