Integral lifting clamp splint tip mouth type automatic bag clamping device

An overall lifting and sharp-mouth type technology, applied in the direction of packaging automatic control, packaging, solid materials, etc., can solve the problems of slow switching between empty bags and full bags, affecting the packaging capacity of automatic packaging machines, etc., to speed up the handover speed, improve The effect of packaging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

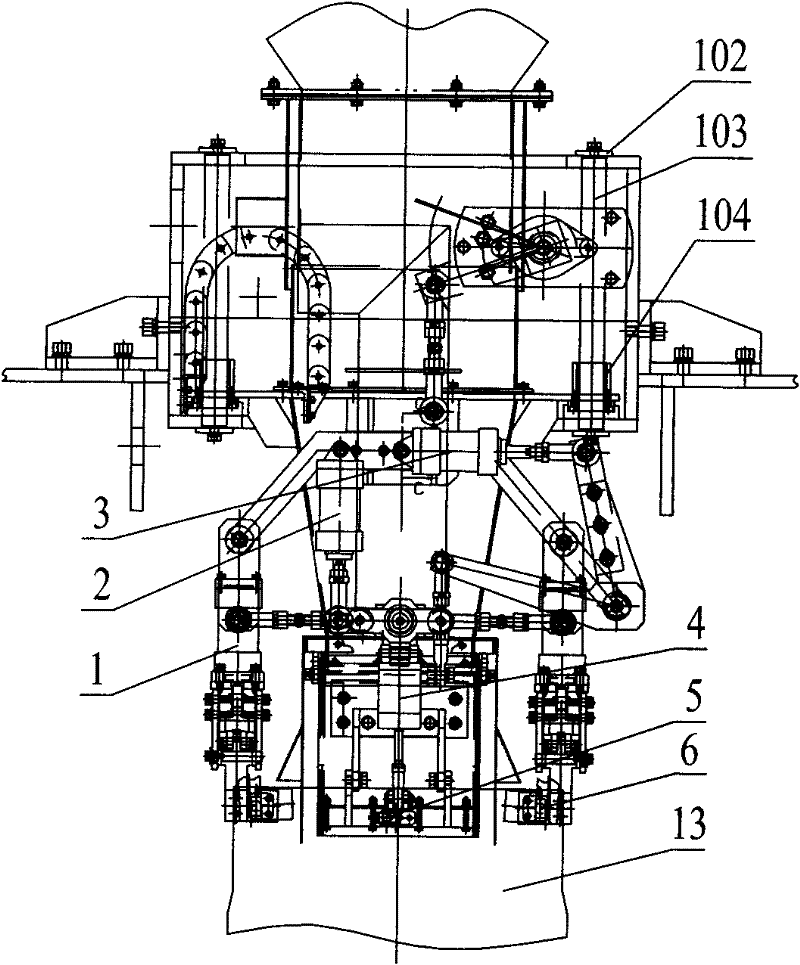

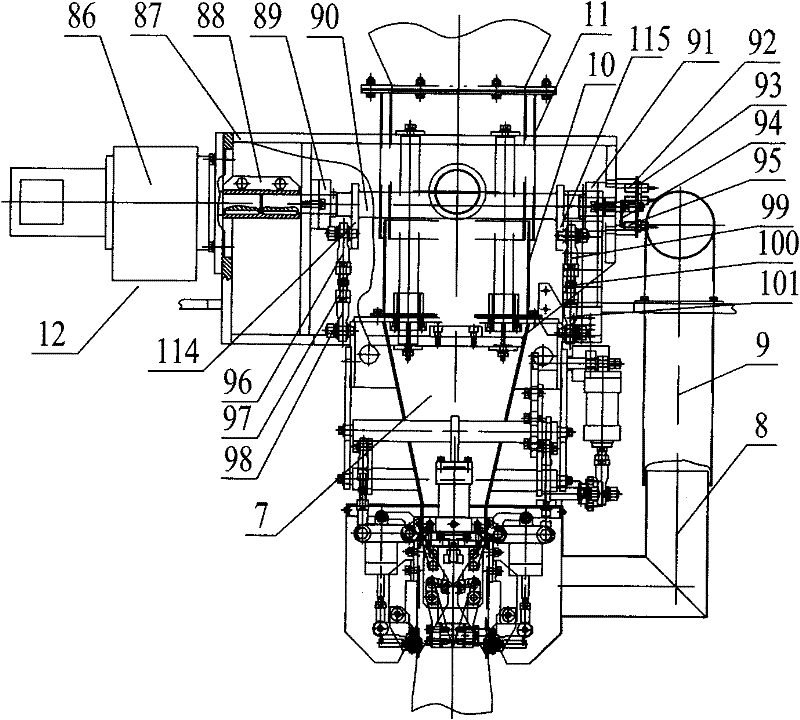

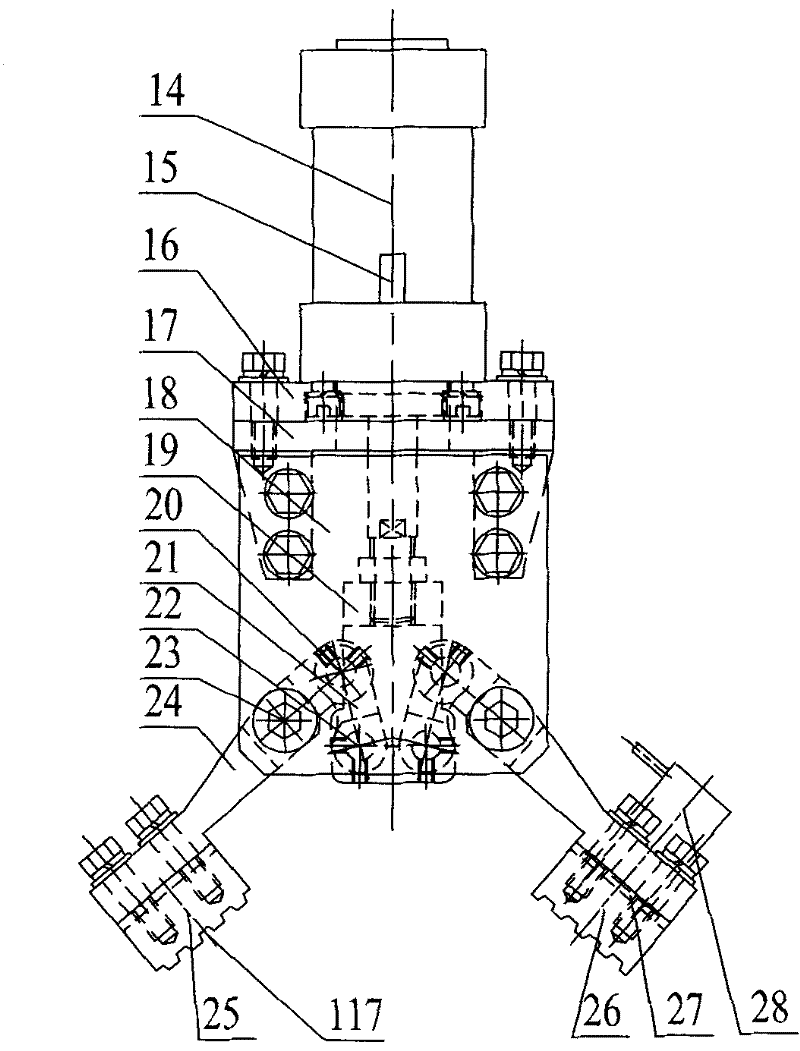

[0025] Such as figure 1 , figure 2As shown, the present invention is mainly composed of clamp bag mechanism 1, clamp pull-shrink whole bag mechanism 2, feeding nozzle filling mechanism 3, plywood bag mechanism 4, splint judging device 5, tong judging device 6, bag Clamp body 7, draft dust removal cover 8, draft dust removal pipe 9, inner connecting pipe 10, outer connecting pipe 11, bag folder elevating mechanism 12 and other components.

[0026] Such as figure 1 , figure 2 As shown, the bag clip body 7 is installed on the bag clip lifting mechanism 12, and the bag clip lifting mechanism 12 is fixed on the frame of the automatic packaging machine, and the upper part of the bag clip body 7 is connected to the blanking pipeline; Fixed on the bag clamp body 7, a set of clamp bag mechanism 1 is installed on both sides of the clamp pull-shrink whole b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com