Self-reliance sealing device of wind pipe connecting end

A technology for connecting ends and air ducts, applied in the direction of pipeline layout, pipe/pipe joints/pipe fittings, pipe components, etc., can solve the problems of inability to adjust the valve closure in time, high cost, electric accidents, etc., to shorten the self-cleaning time, use safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

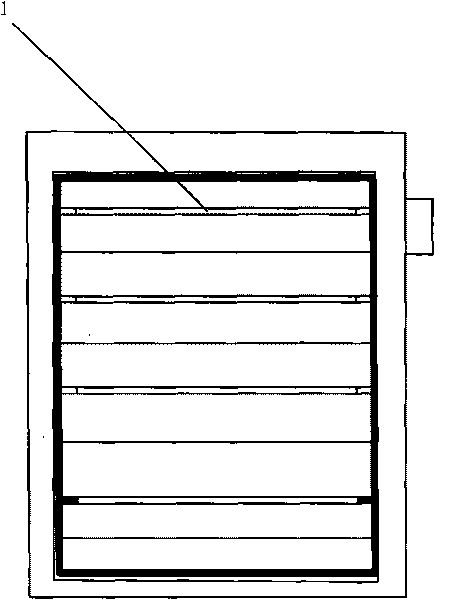

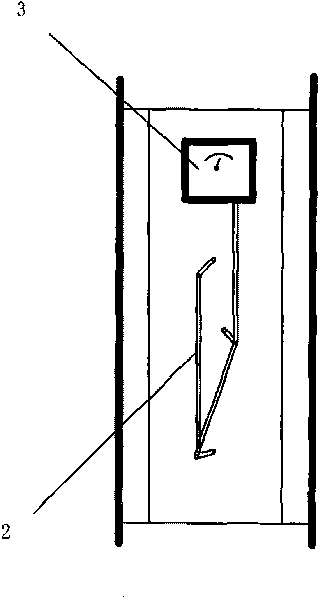

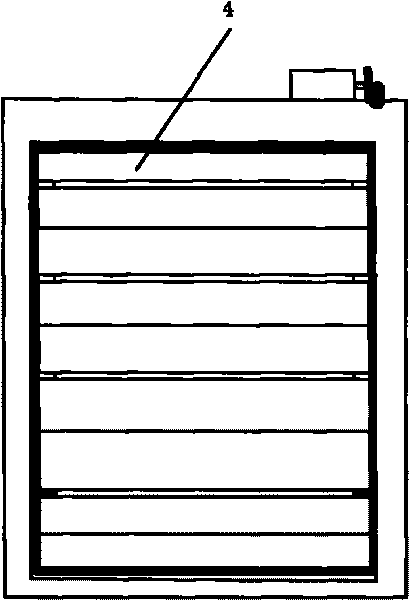

[0017] Such as image 3 , 4 As shown, the present invention is applied to the self-sealing device of the air duct connection end of the movable space and the fixed space, wherein such as image 3 for its on state, Figure 4 Its closed state includes the fixed air duct 1 on the fixed space (not shown in the figure) and the movable air duct 2 on the movable space (not shown in the figure), and the rotating control shaft 5 controls the movable space and the movable wind pipe. For the rotation of the pipe, butt flanges 3 and 3' are respectively provided at the butt ends of the fixed air duct 1 and the movable air duct 2, and connecting flanges 11 and 11 are provided on the air ducts at the inner ends of the butt flanges 3 and 3'. ', the airtight valves 4, 4' are airtight split multi-leaf regulating valves, which are installed between the connecting flanges 11, 11' and the butt flanges 3, 3', and the airtight valves 4, 4' are controlled by the driving device. close.

[0018] Su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com