Method for controlling silicon filtering and recycling system

A control method and filter press technology, which is applied in the field of filter press manufacturing, can solve problems such as unscientific control methods, low filtration efficiency, and insufficient washing, so as to achieve intuitive and convenient control, improve filtration efficiency, and shorten the time for unloading cakes. the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

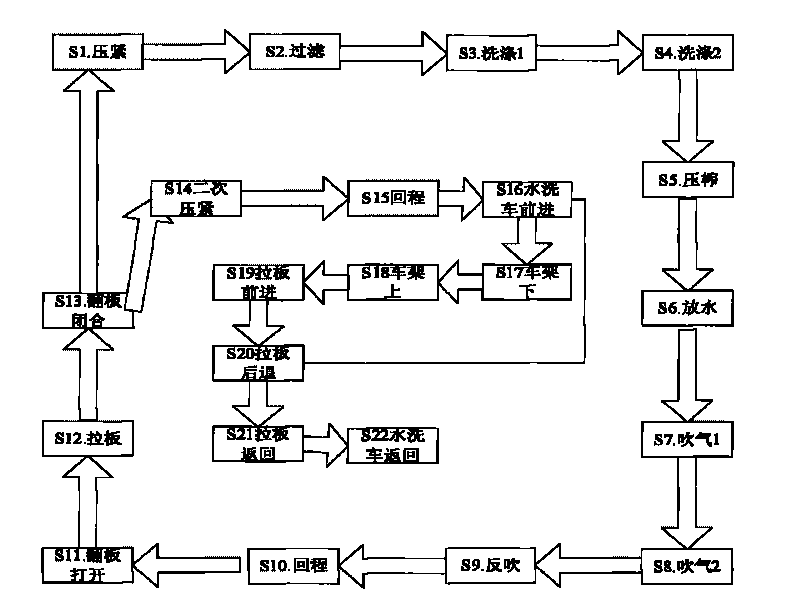

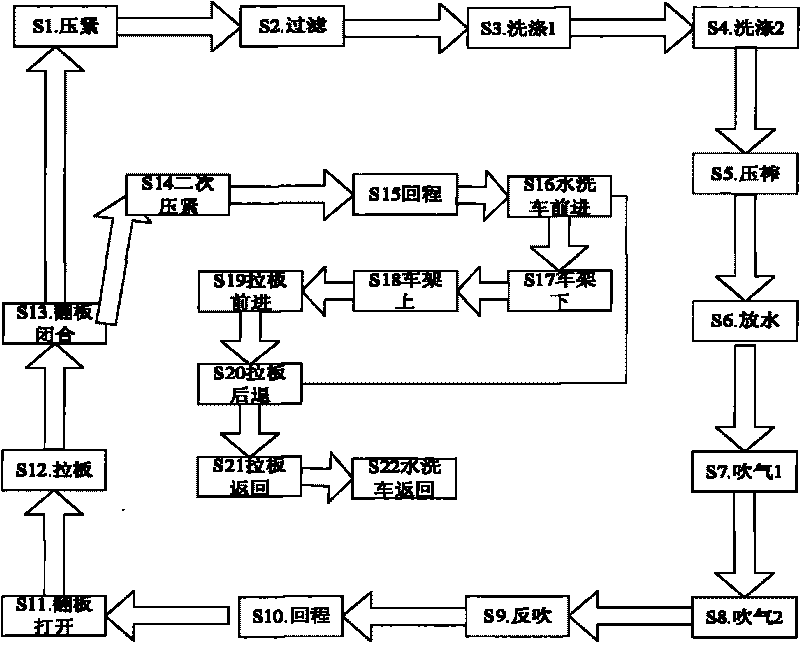

[0008] Example 1: Refer to the attached figure 1 . A control method for filtering and recycling silicon system, which is characterized by: (1) The process graphics design is required on the touch screen, and each state can be displayed, and each parameter is set on the screen, and each alarm state is displayed, using text Display; (2) An alarm is required, and the reset is reset by touching the button. There are emergency stop buttons and washing cloth selector knobs on the electric control box; (3) There should be buttons for various actions and automatic buttons on the touch screen; stop button - --The filter press will stop working in any state of the filter press, and will be cleared in any manual state; in the automatic state, the pause button will not clear the pressure holding state; (4) The above actions are all single Step and automatic action control; (5) Water flushing. All cleaning states are effective when the cloth selection knob is in the cleaning state. The num...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com