Rivet

A technology of rivets and rivet caps, applied in rivets and other directions, can solve problems such as uneven force, uneven flanging, and affecting riveting strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

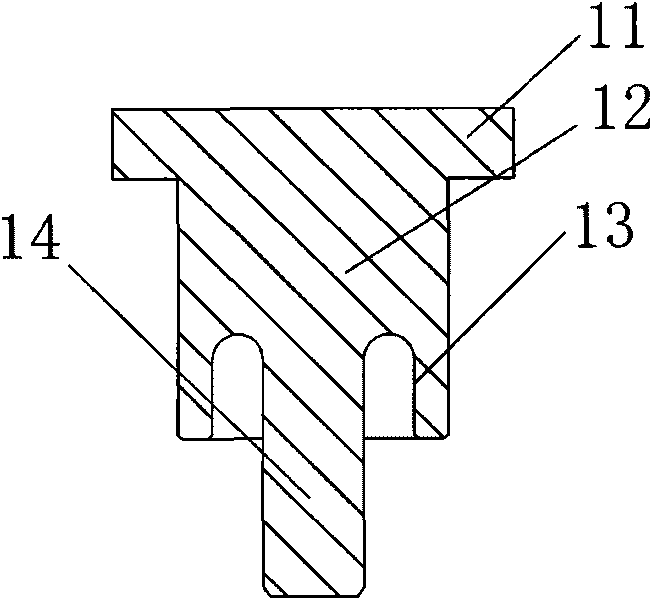

[0015] Such as figure 2 As shown, the rivet of this embodiment includes a cylindrical rivet body 12 with a rivet cap 11 at one end, and a hollow flanging structure at the other end of the rivet body away from the rivet cap, and the flanging structure is arranged on the rivet The axial groove 13 at the end of the body, the groove wall of the groove 13 is used for flanging and riveting; the end of the rivet body away from the rivet cap is also provided with a guide post 14 coaxial with the rivet body, the guide The posts 14 are arranged in the groove 13 at intervals, one end of the guide post 14 is fixedly connected to the bottom of the groove 13 , and the other end protrudes from the notch of the groove 13 .

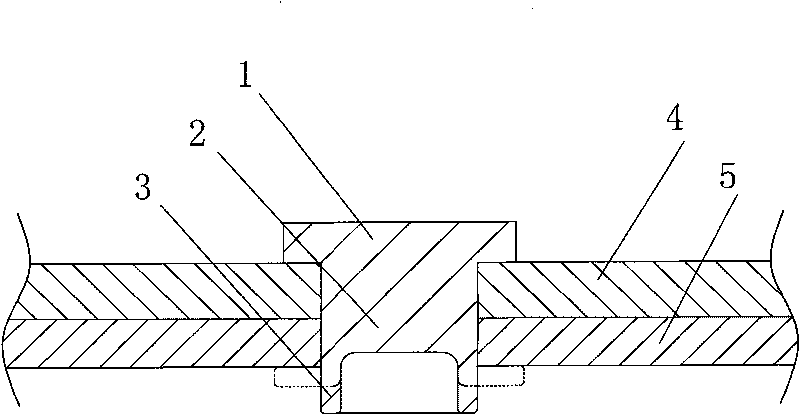

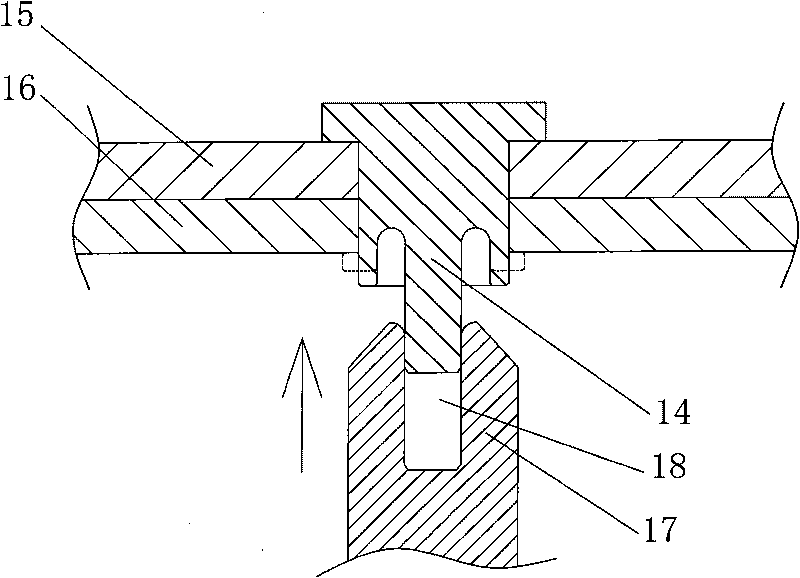

[0016] When the rivet of this embodiment is in use, such as image 3 As shown, the rivet body is first inserted into the riveting holes of the riveting fasteners 15, 16, so that the rivet cap is pressed against one of the riveting fasteners 15, and then the flanging str...

Embodiment 2

[0018] Such as Figure 5 As shown, the structure of the rivet of this embodiment is the same as that of Embodiment 1, the difference lies in that a thread 20 is provided on the outer peripheral surface of the guide post 14 of the rivet. The method of using the rivet in this embodiment is the same as in Embodiment 1, the difference is that a safety nut 19 can be screwed on the guide post 14 after flanging treatment, which not only increases the riveting strength, but also prevents the groove wall from flanging The resulting sharp openings will cause damage to personnel.

Embodiment 3

[0020] The structure of the rivet in this embodiment is the same as that in Embodiment 1, and can be used in the lead-out structure of the battery or supercapacitor pole, wherein the guide post can be used as the lead-out end of the positive and negative poles of the battery or supercapacitor. Such as Figure 6 As shown, 50 in the figure is an end cover of a battery or a supercapacitor, and a through hole 52 is opened in the center of the end cover 50, and a rivet is inserted upside down in the through hole 52; the rivet body 12 of the rivet and the through hole 51 An insulating sealing sleeve 53 is tightly sealed between the hole walls, and the upper and lower ends of the insulating sealing sleeve 53 protrude from the aperture of the through hole 51 respectively, and the lower end of the insulating sealing sleeve 53 is clamped between the rivet cap 11 and the top cover 50 of the rivet. Between the lower surfaces; a gasket 54 is set on the upper part of the rivet body 12 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com