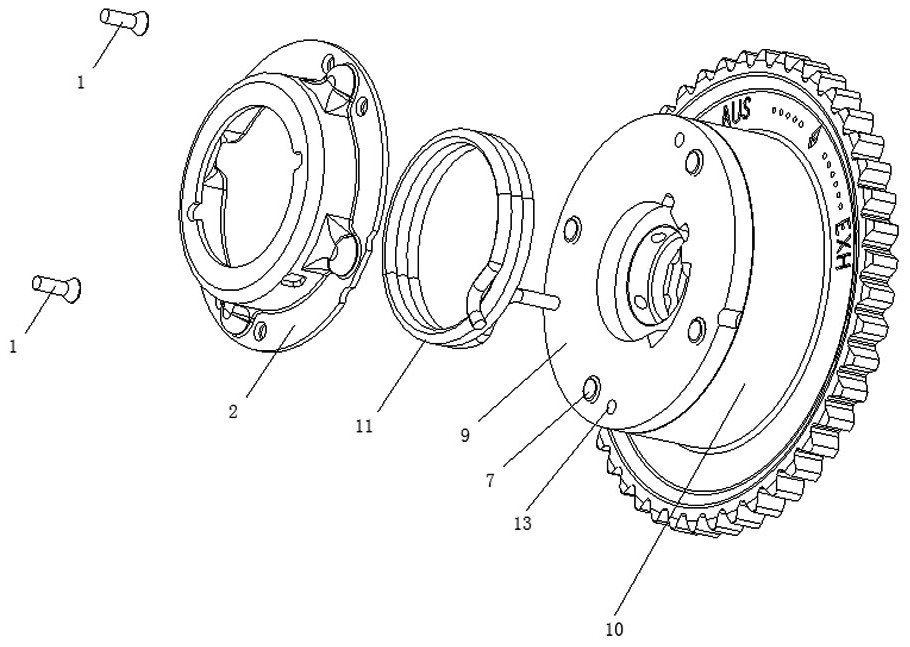

Guard for securing the torsion spring at the front end of the camshaft phaser

A phase adjuster and camshaft technology, which is applied in the direction of machines/engines, valve devices, mechanical equipment, etc., can solve the problems of difficult installation of torsion springs and loose torsion springs, so as to simplify the assembly process and increase the riveting strength of rivets , the effect of reducing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

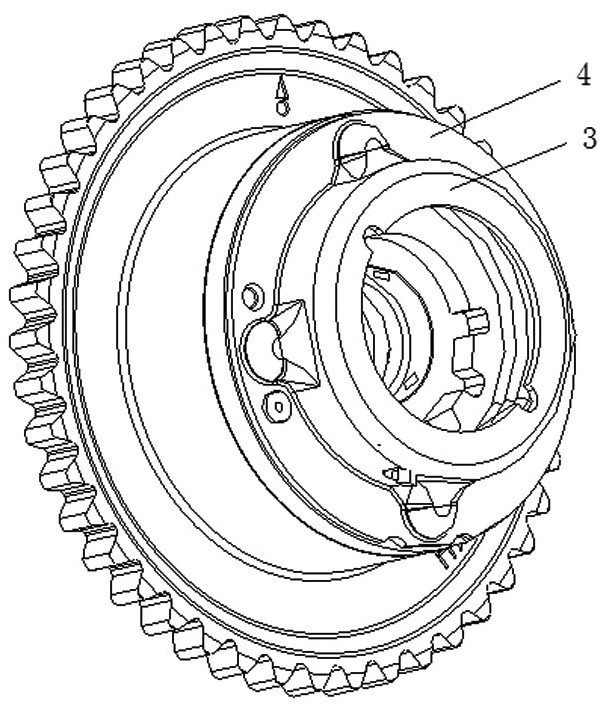

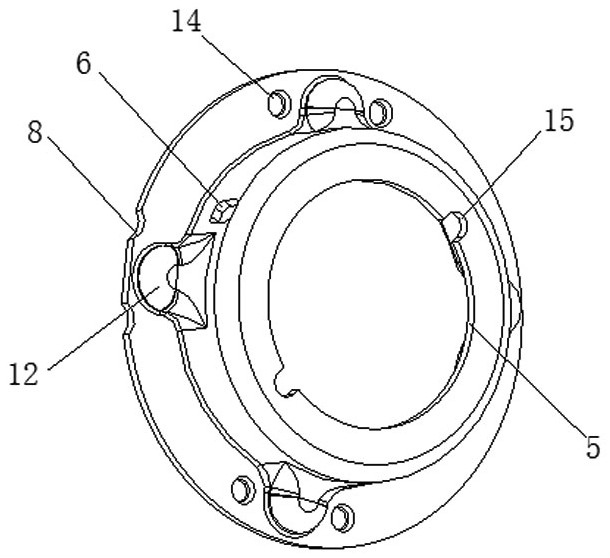

[0022] See Figure 1 to Figure 4 , the present invention has a shroud 2 that is riveted with the cover plate 9 of the phaser 10 by pressing the tail of the rivet 1; The center of the cover 2 is provided with an avoidance hole 5 for easy assembly and disassembly of the central bolt; a torsion spring fixing port 6 is provided on the side wall of the torsion spring cover 3, and the torsion spring 11 is placed in the inner cavity of the torsion spring cover 3; The annular array on the outer ring 4 has four avoidance grooves 12 that facilitate the full threaded contact between the mounting screw 7 and the cover plate 9 and increase the tightening force of the mounting screw 7 and four concentric with the rivet holes 13 on the cover plate 9 of the phaser 10 And one-to-one correspondence with the rivet holes 14 of the shield, the opening of the rivet hole 14 of the shield has a chamfer, which increases the riveting pressure of the rivet 1 and the riveting strength of the rivet 1, use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com