Stepless adjustment device for fixture frame

A stepless adjustment and fixture technology, applied in measuring devices, material analysis by optical means, instruments, etc., can solve problems such as affecting work efficiency, affecting inspection quality, trouble, etc., to facilitate operators, improve inspection efficiency, and simplify operations. effect of the program

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

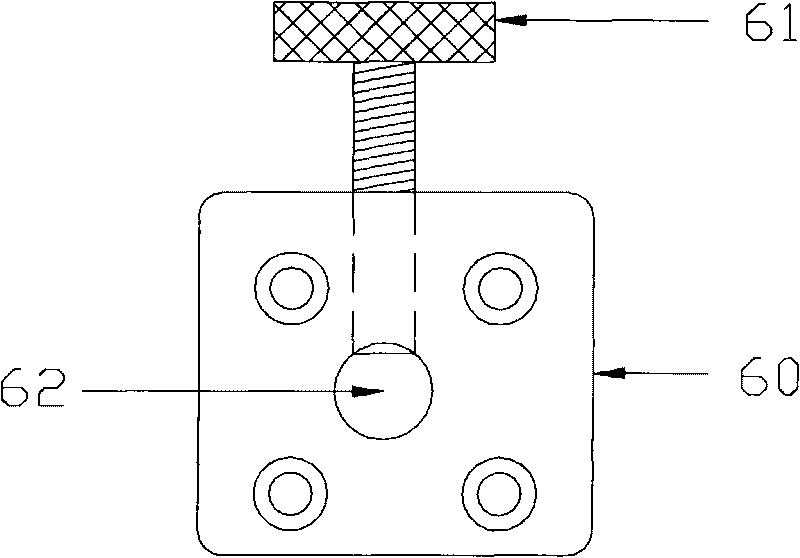

[0014] Such as figure 1 A clamp frame stepless adjustment device shown includes a positioning slider 60, a sliding hole 63 is provided in the middle of the positioning slider 60, a positioning screw 61 is arranged vertically above the sliding hole 63, and the positioning screw 61 and The positioning sliders 60 are threadedly connected.

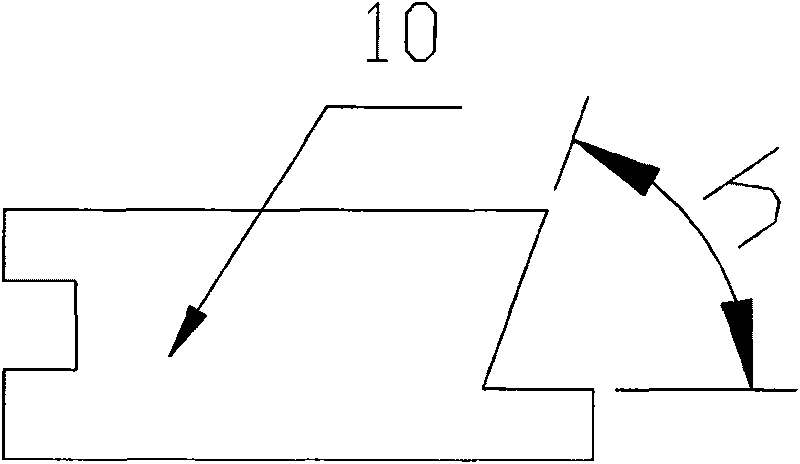

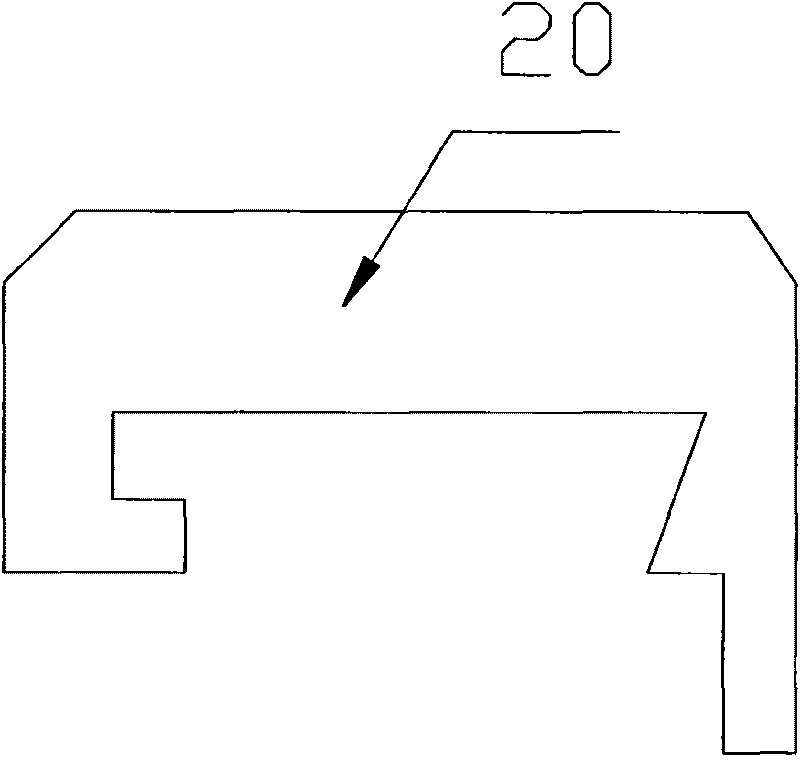

[0015] Such as figure 2 , Figure 4 As shown, specifically: push-pull rods 50 are erected on both sides of the PCB fixture frame 40 respectively, the push-pull rods 50 are provided with positioning sliders 60, and the push-pull rods 50 pass through the sliding holes 62 of the positioning sliders 60 Over, the sliding connection between the positioning slider 60 and the push-pull rod 50, the positioning slider 60 is provided with a front bar-shaped loading table 10 for clamping the PCB board 30, and the two ends of the front bar-shaped loading table 10 are used The fastening parts are respectively fixed on the two positioning sliders 60 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com