Inner and outer ring combined device of bearing

A combination device, inner and outer casing technology, applied in the direction of bearing components, shafts and bearings, mechanical equipment, etc., can solve problems such as complex structure, low production efficiency, equipment operation failure, etc., achieve simple and compact structure, improve production efficiency, and reduce labor The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

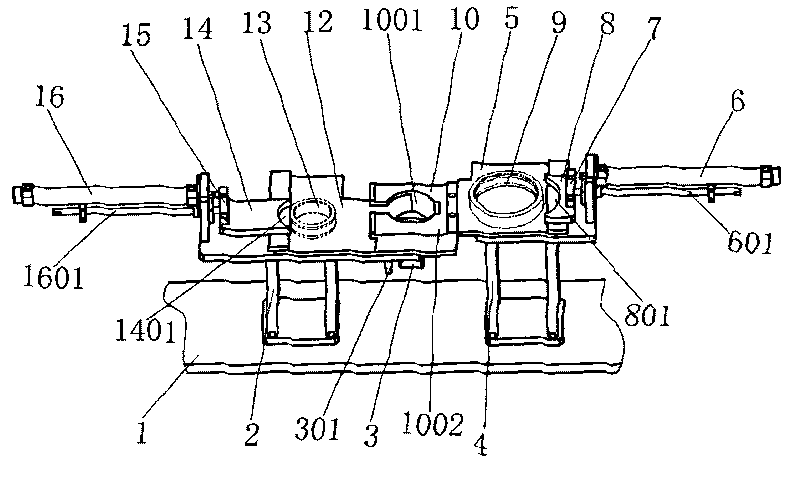

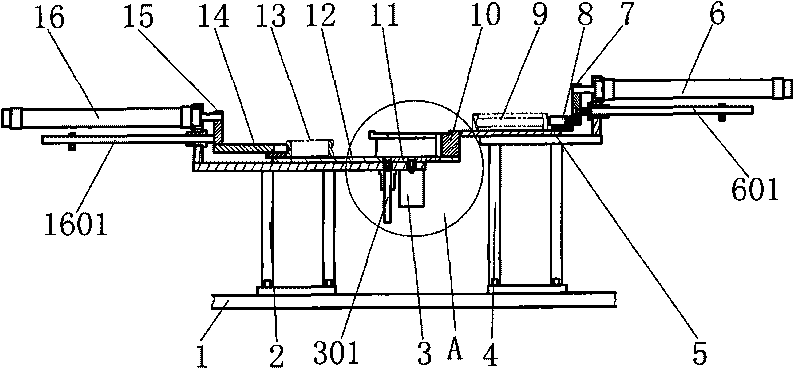

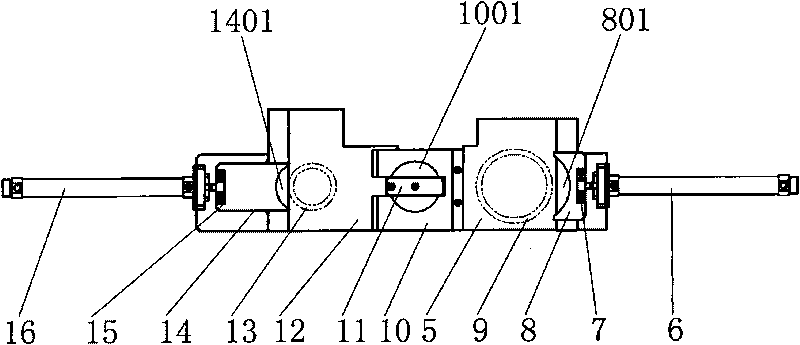

[0019] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0020] Such as figure 1 , 2 , 3, and 4, the present invention includes a base plate 1, the inner ring pushing support 2 and the outer ring pushing support 4 are installed on both sides of the base plate 1, and the inner ring material channel plate 12 is installed on the inner ring pushing support 2, the outer ring material channel plate 5 is installed on the outer ring material pushing support 4, and the installation height of the inner ring material channel plate 12 is lower than the outer ring material channel plate 5. The combined mold base 10 is installed on the inner ring material channel plate 12 and connected to the outer ring material channel plate 5. The upper plane of the combined mold base 10 is flush with the outer ring material channel plate 5. In this embodiment, the combined mold base 10 is flat Outer ri...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap