Methods of Encapsulating Surface Mount Components

A packaging surface, surface mount technology, applied in the direction of electrical components, impedance networks, etc., to prevent cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings.

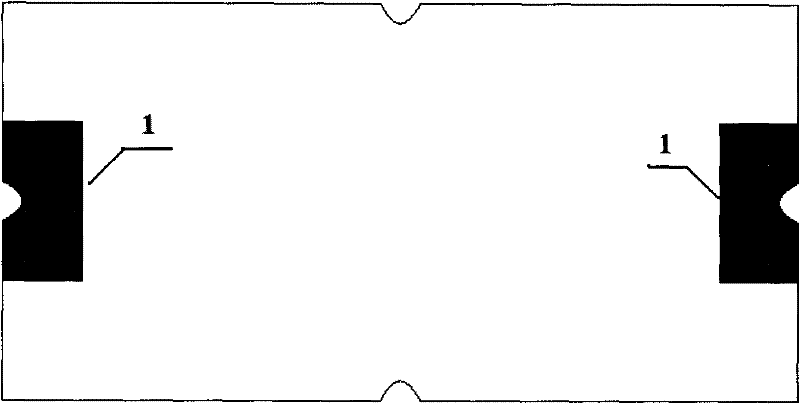

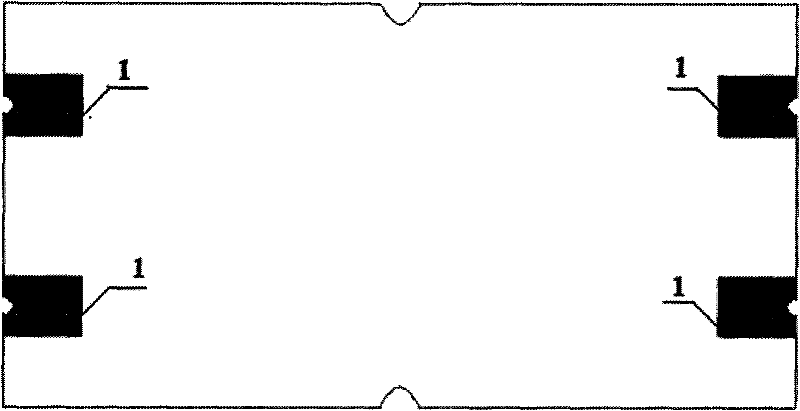

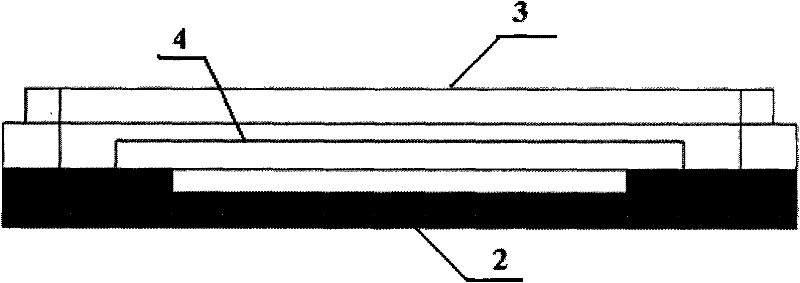

[0026] see Figure 7 , Figure 8 with Figure 9 , the present invention comprises the following steps:

[0027] A10. First print a layer of solder 5 on the solder joint (i.e. electrode 1) on the base 2 of the surface mount component or on the position corresponding to the solder joint on the substrate 7, and then print a layer of solder 5 on other parts Filled solder or filled epoxy resin 6 with the same thickness, the filled solder or filled epoxy resin 6 and the above-mentioned solder 5 are provided with a gap 15, and the two cannot contact each other to ensure that the solder 5 is filled with solder or filled with epoxy resin 6. It is non-conductive between them to prevent the short circuit of the solder joints of the base 2 of the surface mount components. The above printings are all screen printing; filled with solder or filled with epoxy resin 6 and printed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com