Postpositioned reversal ditching machine

A ditching machine, rear-mounted technology, applied in the direction of digging/covering ditches, tillage equipment, agricultural machinery and equipment, etc., can solve problems such as poor quality and effect of ditching, falling on both sides of the ditch, laborious operation, etc. , to achieve the effect of light operation, low power consumption and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

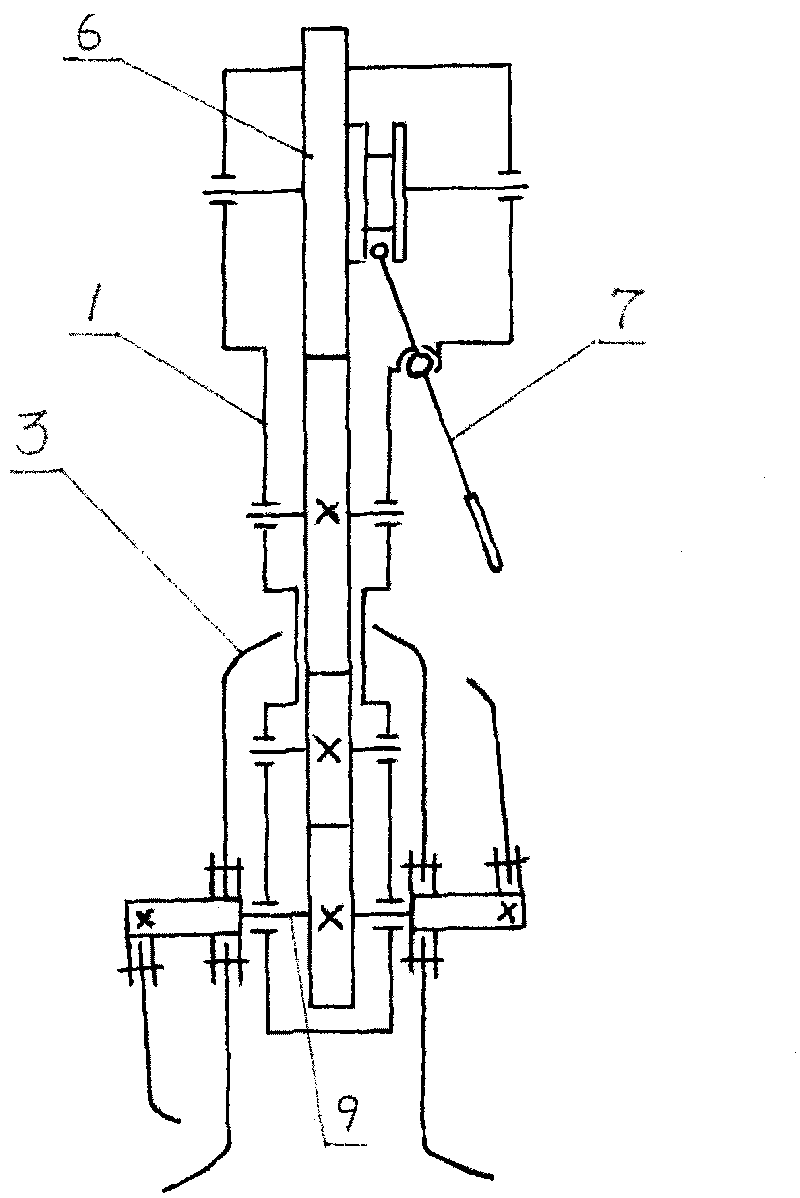

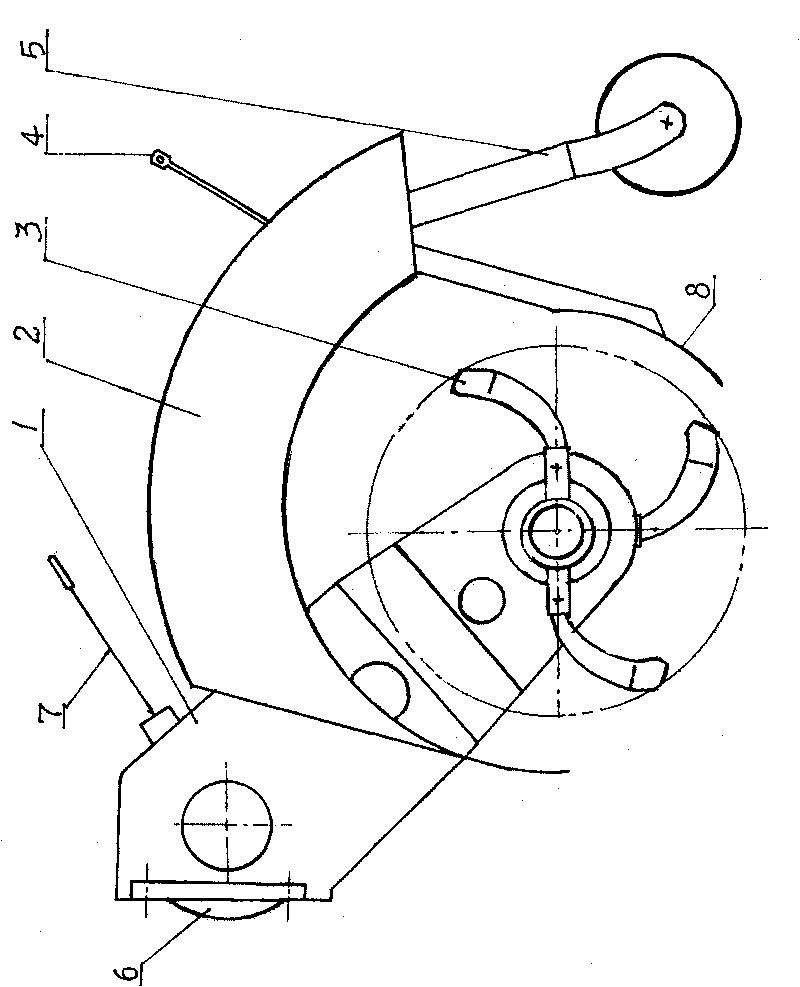

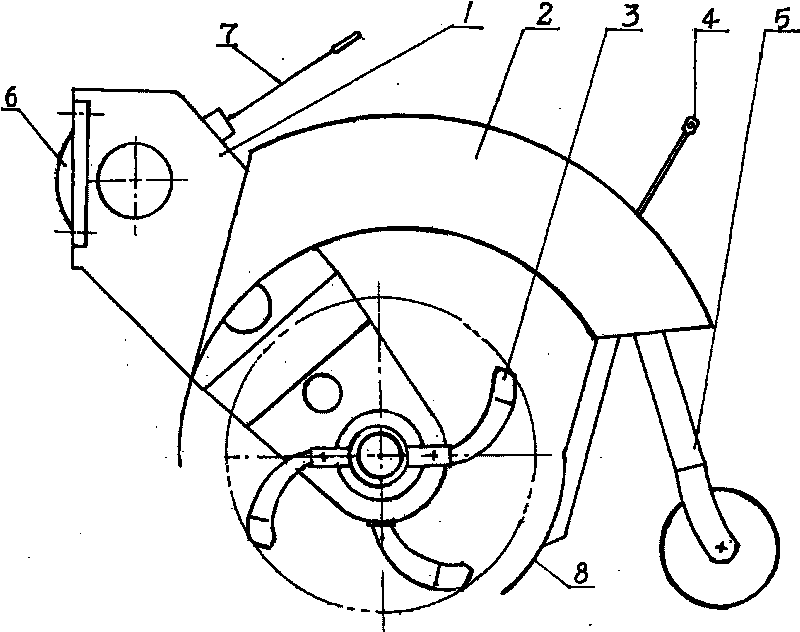

[0010] Such as figure 1 , figure 2 The rear-mounted reverse ditching machine shown includes an intermediate transmission case 1, an input gear 6, and a rotary cutter 3 fixed on the shaft ends of the power output shaft 9 on both sides of the lower part of the intermediate transmission case 1. A fender 2 is arranged on the upper front of the fender 2, and a shovel plate 8 is arranged on the rear and lower part of the fender 2. The tail wheel 5 is fixed on the fender 2, and the strut 4 is connected and fixed with the hand-towed handrail frame. The joystick 7 meshes the input gear 6 with the gear of the hand-drawn gearbox, the power is transmitted to the rotary cutter 3 through the output shaft 9, the rotary cutter 3 rotates in the opposite direction, the tail wheel 5 adjusts and controls the depth, and the middle transmission box 1. The width of the part where the rotary cutter 3 rotates is 25 mm to 50 mm. The part of the soil between the ditch that has not been rotary cut is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com