Magnetic turn-over device of sorting machine

A sorting machine and magnetic technology, used in sorting, transportation and packaging, conveyor objects, etc., can solve the problems of type limitation, inability to forge objects to receive complete inspection, inability to distinguish directions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

[0017] Before the present invention is described in detail, it should be noted that in the following description, similar elements are denoted by the same reference numerals.

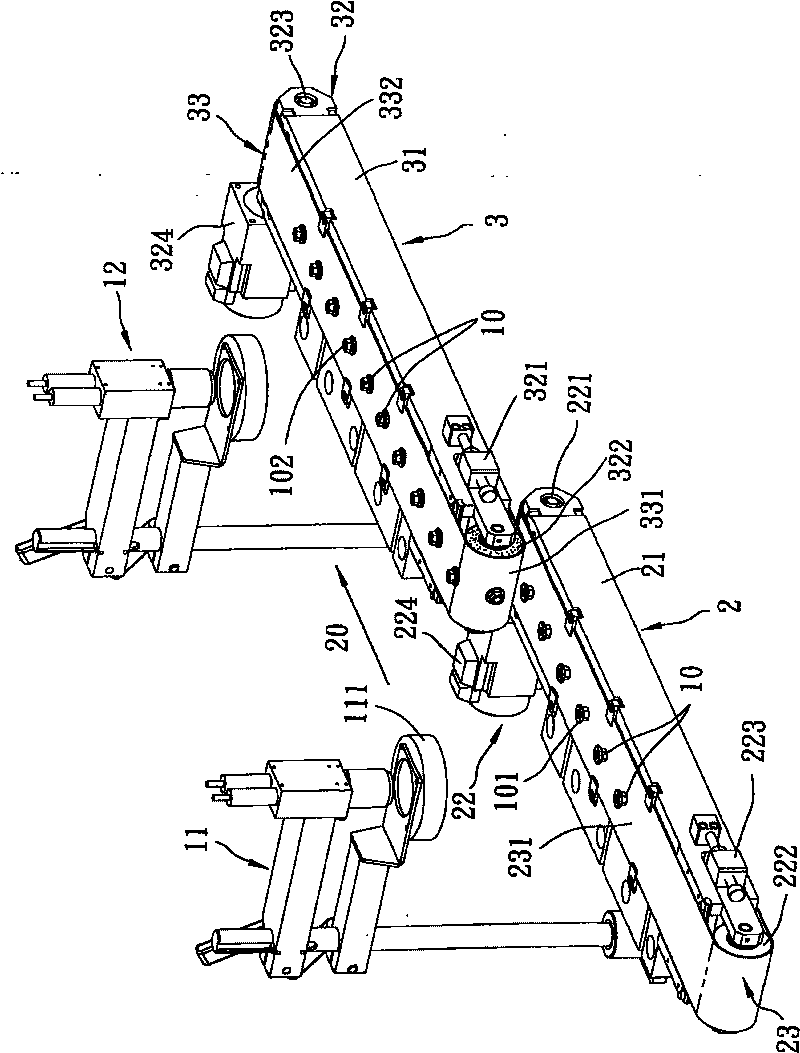

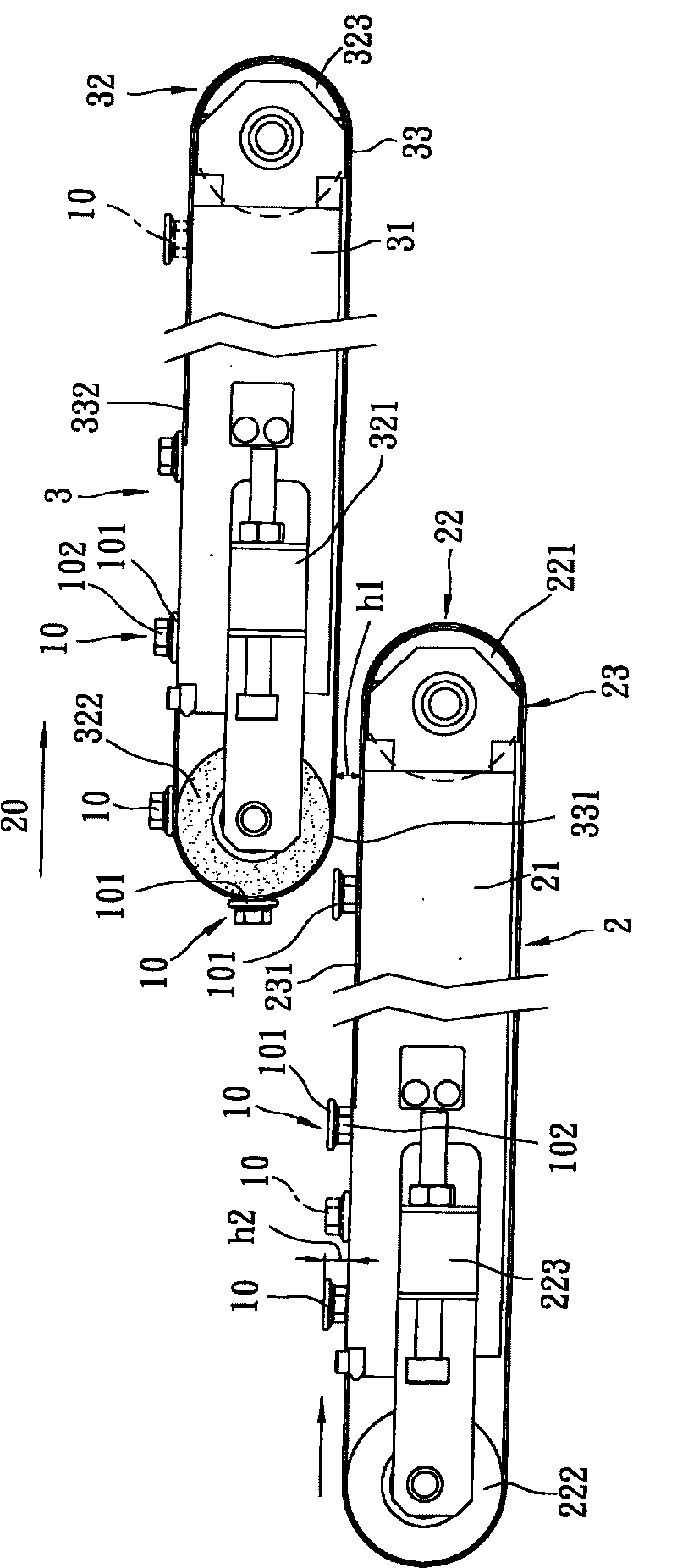

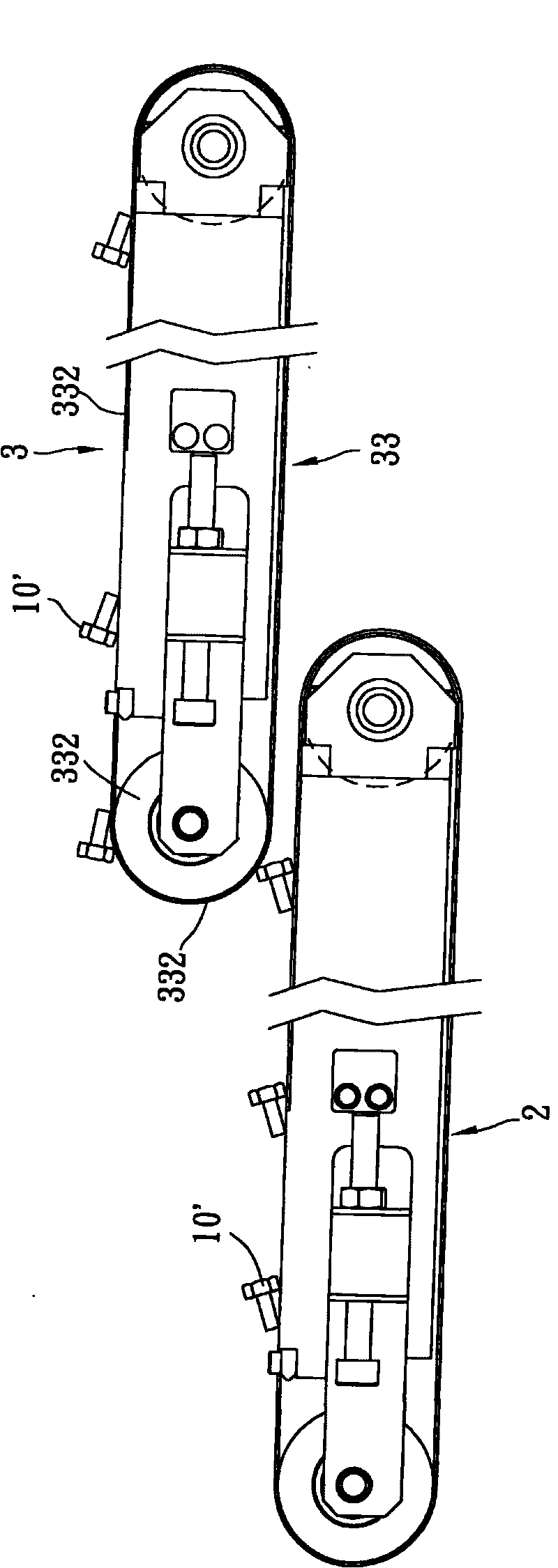

[0018] refer to figure 1 , 2 , the first preferred embodiment of the magnetic flipping device of the present invention is suitable for transporting several magnetic objects 10 with magnetism, and cooperates with two detectors 11 and 12 spaced before and after to detect the magnetic objects 10. figure 1 The detectors 11 and 12 shown in are used to detect the integrity of the surface of the magnetic object 10, but as long as the magnetic object 10 needs to be turned over in the process of detecting various physical properties of the magnetic object 10, the magnetic turning device of the present invention is suitable for use . Furthermore, the magnetic object 10 disclosed in this embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com